Detection device and method for chemical-mechanical polishing end point of copper

A chemical-mechanical and end-point detection technology, which is applied to grinding devices, grinding machine tools, and parts of grinding machine tools, can solve problems such as increasing circuit impedance and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

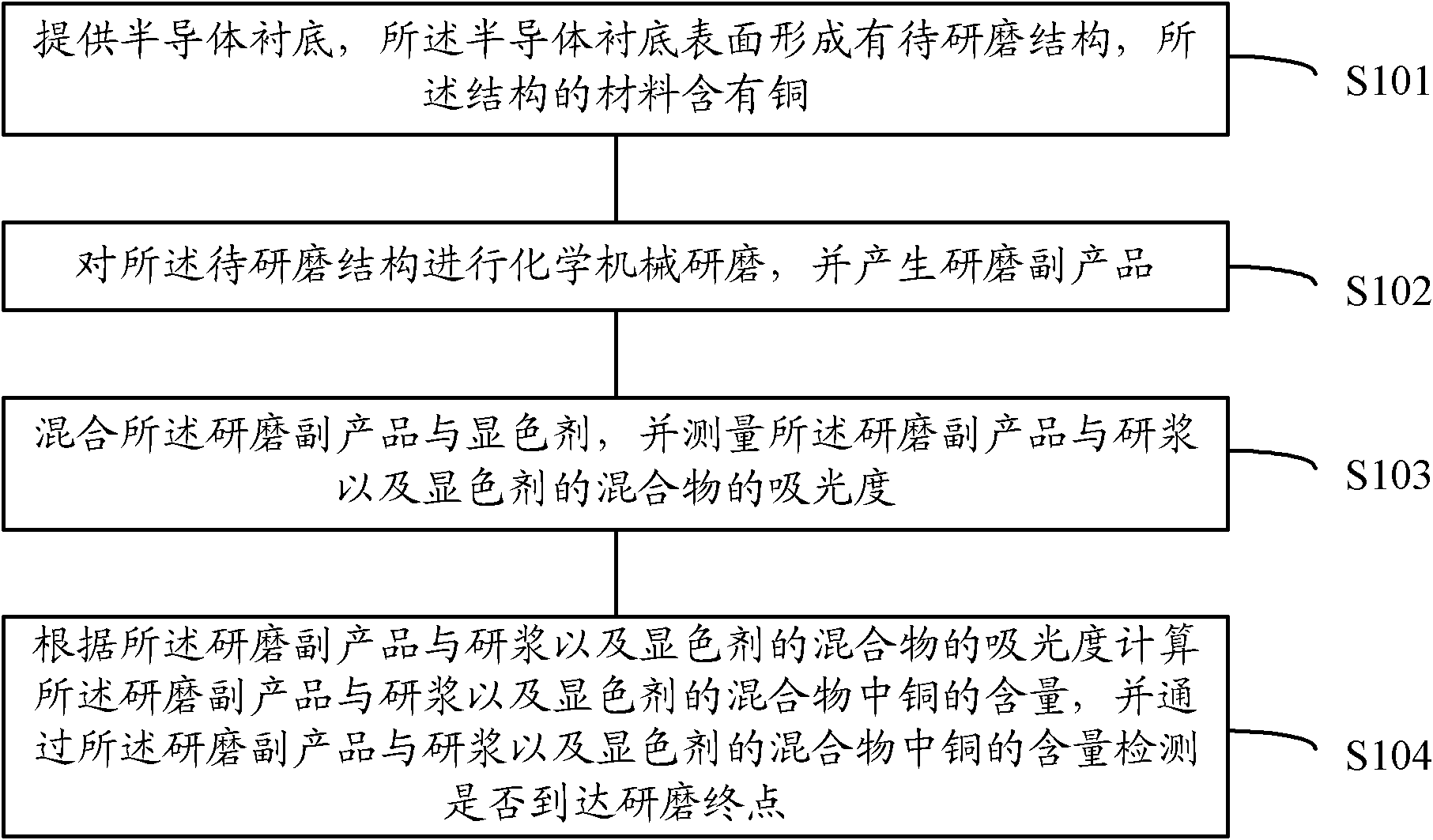

[0038] It can be seen from the background art that detecting the polishing end point is a difficult point in the chemical mechanical polishing process, and it is more and more important to accurately detect the polishing end point of the chemical mechanical polishing of the structure to be polished. The inventor studies the above-mentioned problems, and tries to find a physical quantity that is directly related to the content of copper in the grinding by-product and is convenient to obtain by measurement. After many experiments, the inventor finds that the absorbance of the mixture of the copper-containing solution and the chromogen The content of copper in the mixture is related. After further research, the inventor provides a copper chemical mechanical polishing end point detection method and device, and a copper chemical mechanical polishing method in the present invention.

[0039] In the present invention, after the color developer is mixed with the copper-containing solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com