Positioning support device for stir friction welding of storage box cylinder section circular seam

A technology of friction stirring and positioning support, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of increased difficulty in welding large thin-walled storage tank girth seams, poor resistance to deformation, and large structural size, etc., to facilitate the overall The effect of positioning, parameter stability, and small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

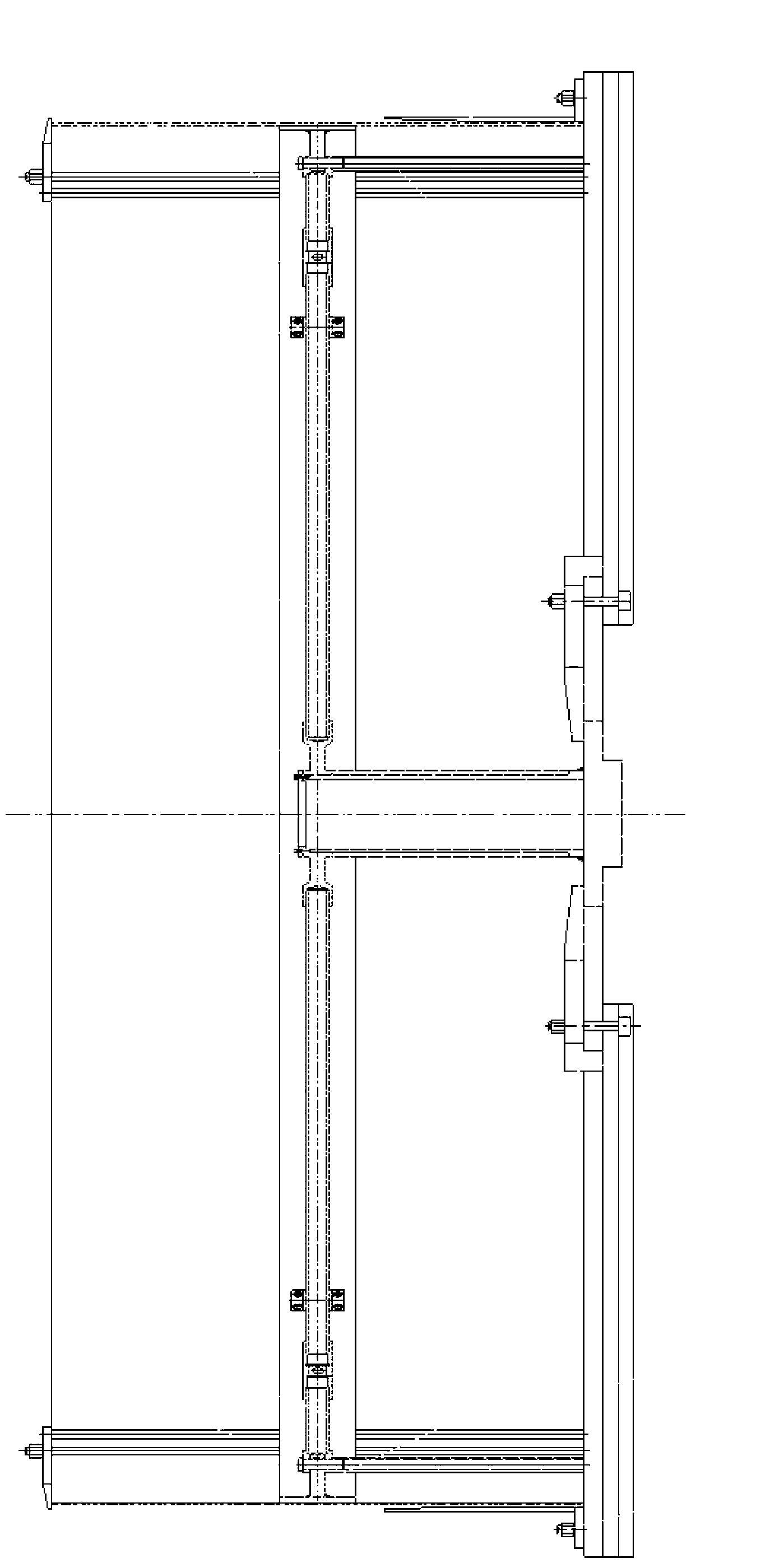

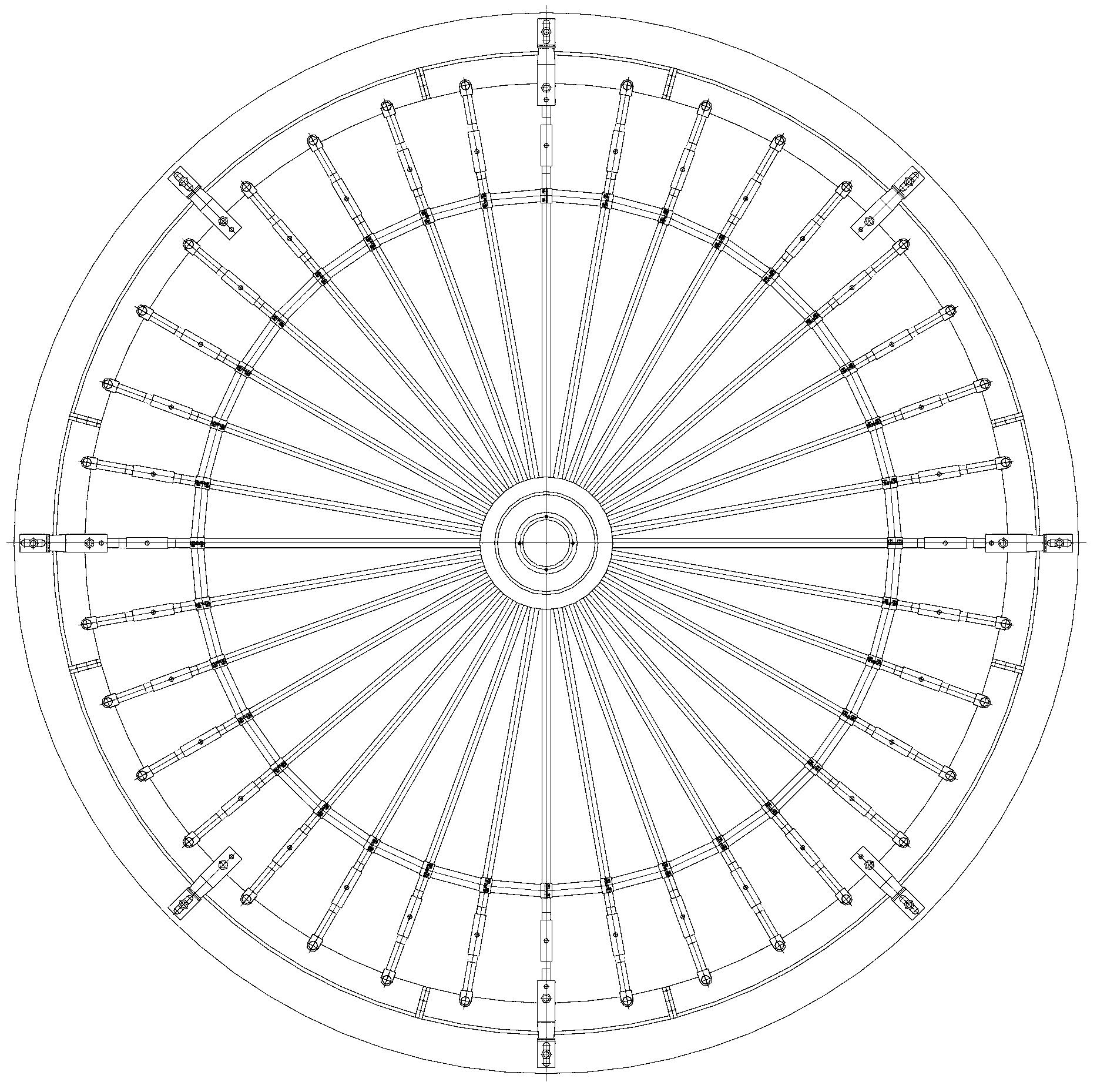

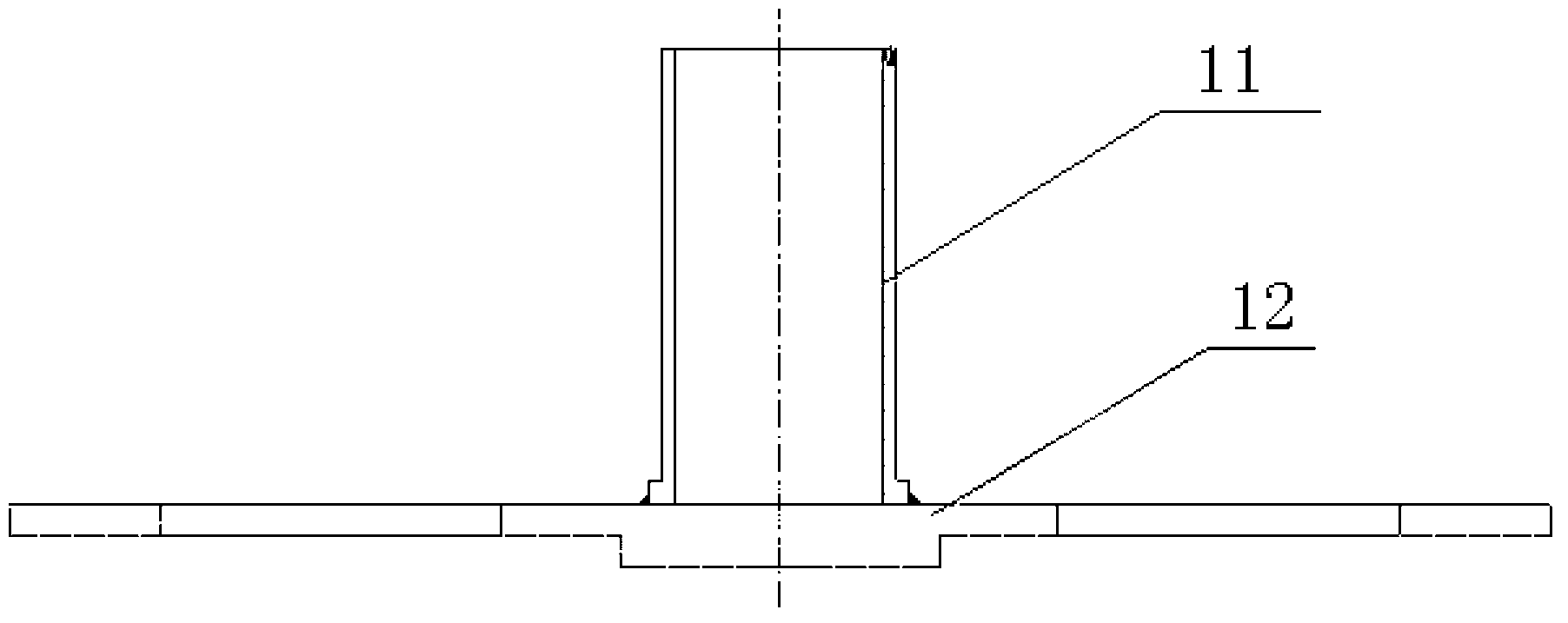

[0030] Such as figure 1 and figure 2 As shown, the rotating base 24 is an annular disc, which is installed on the rotating shaft mechanism and can rotate. The central axis disk 1 is positioned and installed on the rotating base 24 through the positioning platen 18, the positioning bolt 19 and the positioning nut 20. The cylinder body of the central axis disk 1 is covered with a central support ring 2, and its upper end is installed as a top ring 3 through the fixing bolts. Center connecting disc 5 is installed on center supporting ring 2 upper ends, and supporting ring 2 can locate and support central connecting disc 5 simultaneously; Some long struts 6 are fixedly installed by screw thread on the outside of connecting disc 5, 36 are installed in this implementation, in order to make The ends of the extended long struts 6 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com