System and method for realizing automatic failure compensation for power battery

A power battery and automatic technology, applied in secondary battery repair/maintenance, electrical components, circuit devices, etc., can solve problems such as power battery system performance degradation, affecting vehicle operation and reliability, and increasing user costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

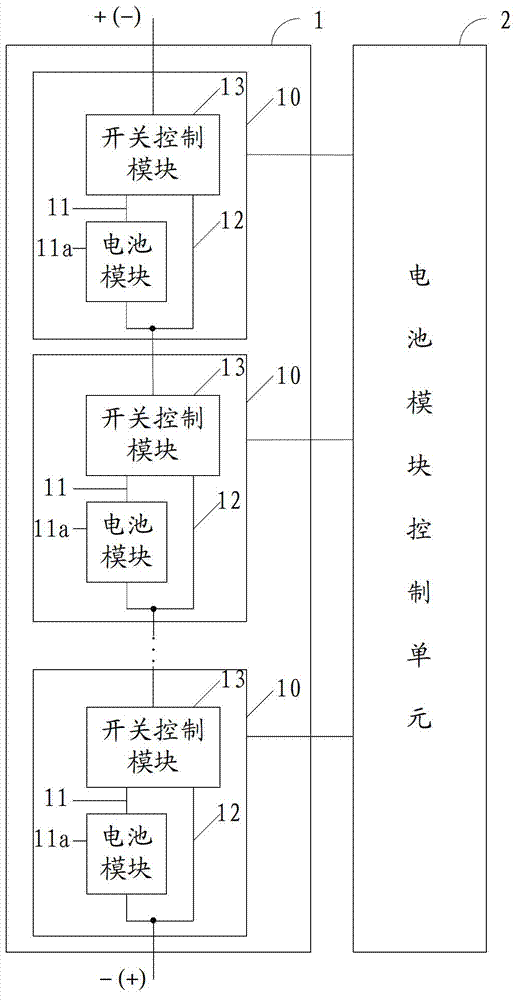

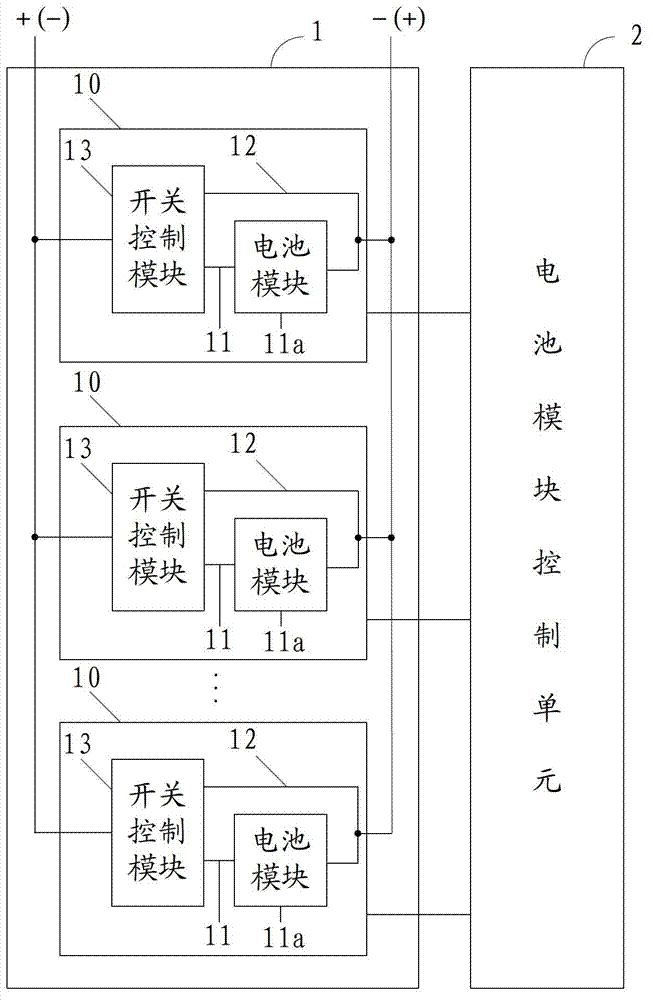

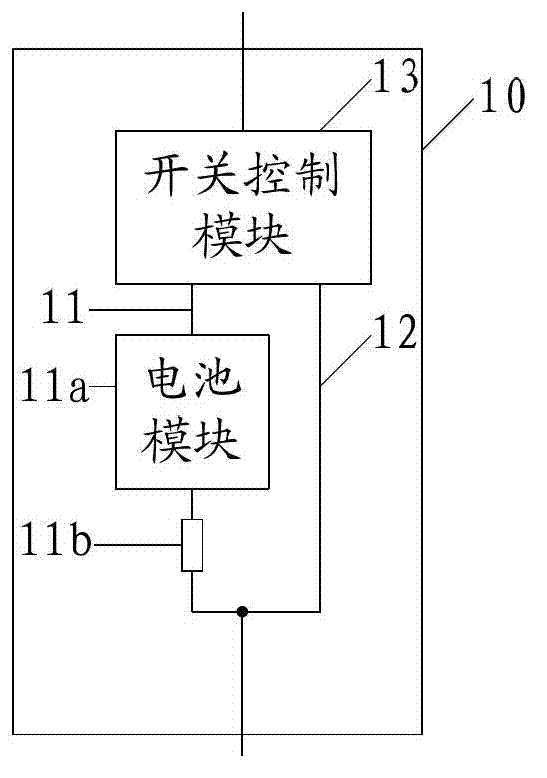

[0081] The present invention proposes a system for realizing automatic failure compensation of the power battery, aiming at the early failure of some battery modules in the battery module in the prior art, which leads to a decrease in the performance of the power battery system, which in turn affects the operation and reliability of the vehicle, and increases the number of users In terms of cost of use, the battery unit is marked as a working battery unit or a reserved battery unit. When the working battery unit fails, the battery module control unit controls the switch control module to isolate the failed battery unit from the battery module. The reserved battery unit is connected to the battery modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com