Adsorption-desorption-seepage experiment system for loaded coal containing gas under condition of varying temperatures

An experimental system and technology for gaseous coal, which is applied in the field of adsorption-desorption-seepage experimental system of gas-containing coal under variable temperature conditions, can solve the problem that it is difficult to reflect the real characteristics of gas-containing coal, cannot meet the needs of scientific research, and the air tightness is not good enough. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

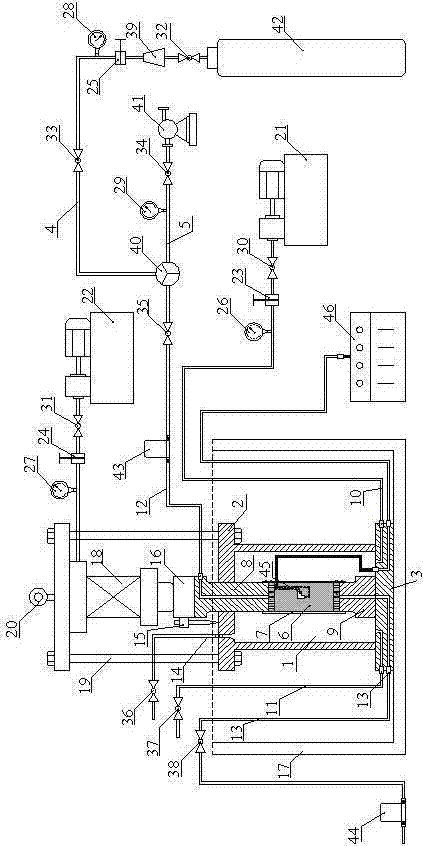

[0022] Depend on figure 1 The shown a gas-containing coal adsorption-desorption-seepage experimental system under variable temperature conditions includes a pool body 17 for holding a constant temperature water bath, a triaxial pressure chamber 1 is arranged in the pool body 17, and a coal room.

[0023] The triaxial pressure chamber 1 is airtight, including the top plate 2, the bottom plate 3 facing up and down, and the side plates surrounded between the top and bottom plates 2, 3. The top plate 2 of the triaxial pressure chamber 1 is inserted with a vertical column Indenter 8, the bottom end of the indenter 8 is located in the triaxial pressure chamber 1, and the top end of the indenter 8 protrudes upwards out of the triaxial pressure chamber 1. The coal chamber is composed of a coal chamber base 9 and a vertical heat-shrinkable tube 7, the coal chamber base 9 is fixed on the upper side of the bottom plate 3 of the triaxial pressure chamber 1, the coal chamber base 9 is opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com