Evaluating method for corrosion of well-reinforcing cement stone

A technology for cementing cement stone and corrosion evaluation, which is applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., to achieve real and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Firstly, according to the SY / T 5546-2002 "Oil Well Cement Applied Performance Test Method" standard, the G-grade cementing cement slurry was prepared.

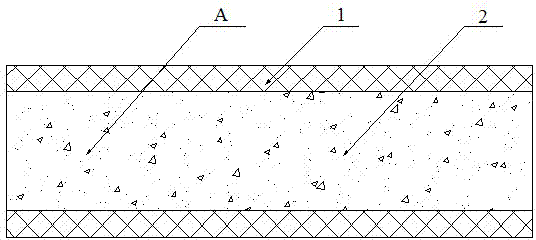

[0024] Pour the prepared G-grade cement slurry into the mold 1 with an inner diameter of 25 mm, a length of 30 mm and a length of 50 mm, seal the mold 1 and place it in a high-temperature and high-pressure curing kettle for curing for 48 hours, so that it can solidify under simulated downhole conditions to form cement stone 2 , Then take out the cement stone sample A that has not removed the mold, and use sandpaper to grind the vitrified surface. According to this method, several cement stone samples A are made according to the test requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com