Method, device and system for measurement of oil injection volume

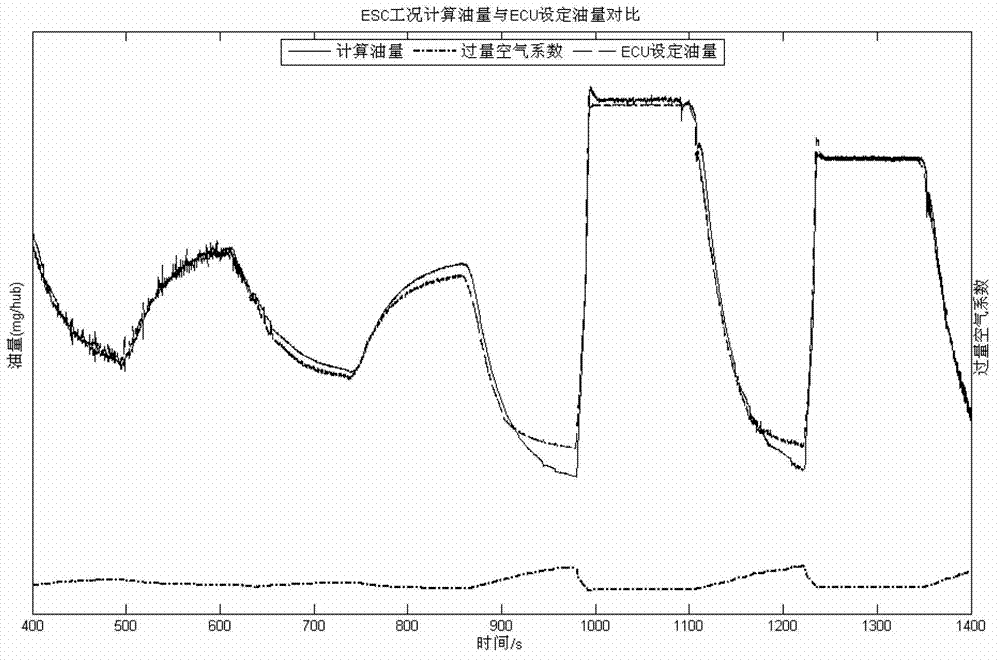

A measurement method and technology of fuel injection quantity, applied in the field of fuel injection quantity measurement method, device and system, can solve the problems that the fuel injection quantity cannot be obtained, the operation of the diesel engine cannot be well controlled, etc., and the actual fuel injection quantity is accurate and calculated The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0070] see figure 1 , which is a flow chart of the first embodiment of the method for measuring fuel injection quantity provided by the present invention, the method includes:

[0071] S101, collecting and obtaining the concentration of oxygen in the exhaust gas.

[0072] In the first embodiment of the present invention, the concentration of oxygen in the exhaust gas is collected by the first collection unit. Specifically, the first collection unit is a nitrogen and oxygen sensor. For example, the SCR system is generally used in high-pressure common rail diesel engines, and the nitrogen oxygen sensor (NOx sensor) is one of the necessary sensors. The O2 content of the exhaust gas can thus be measured with the NOx sensor.

[0073] S102. Calculate an excess air factor by using the concentration of oxygen in the exhaust gas.

[0074] Wherein, the excess air coefficient is calculated according to the following formula:

[0075] λ = ...

no. 2 example

[0083] see figure 2 , which is a flow chart of the second embodiment of the method for measuring fuel injection quantity provided by the present invention, the method includes:

[0084] S201, collecting and obtaining the concentration of oxygen in the exhaust gas.

[0085] Specifically, the concentration η of oxygen in the exhaust gas is collected by a nitrogen and oxygen sensor 1 .

[0086] S202, measure the intake air temperature, the intake air pressure, and the engine speed.

[0087] In this specific embodiment of the present invention, the intake air temperature t is measured by the intake air temperature sensor 1 ; Use the intake pressure sensor to measure the intake pressure P; use the engine speed sensor to measure the engine speed n.

[0088] Those skilled in the art can understand that the order of step S201 and step S202 can be reversed or executed in parallel.

[0089] S203. Calculate an excess air coefficient by using the concentration of oxygen in the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com