Combined type longitudinal finned pipe fume waste heat exchanger

A flue gas waste heat, finned tube technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of complex manufacturing, poor pressure bearing capacity and erosion resistance, and achieve compact structure. , easy to clean, easy to repair the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

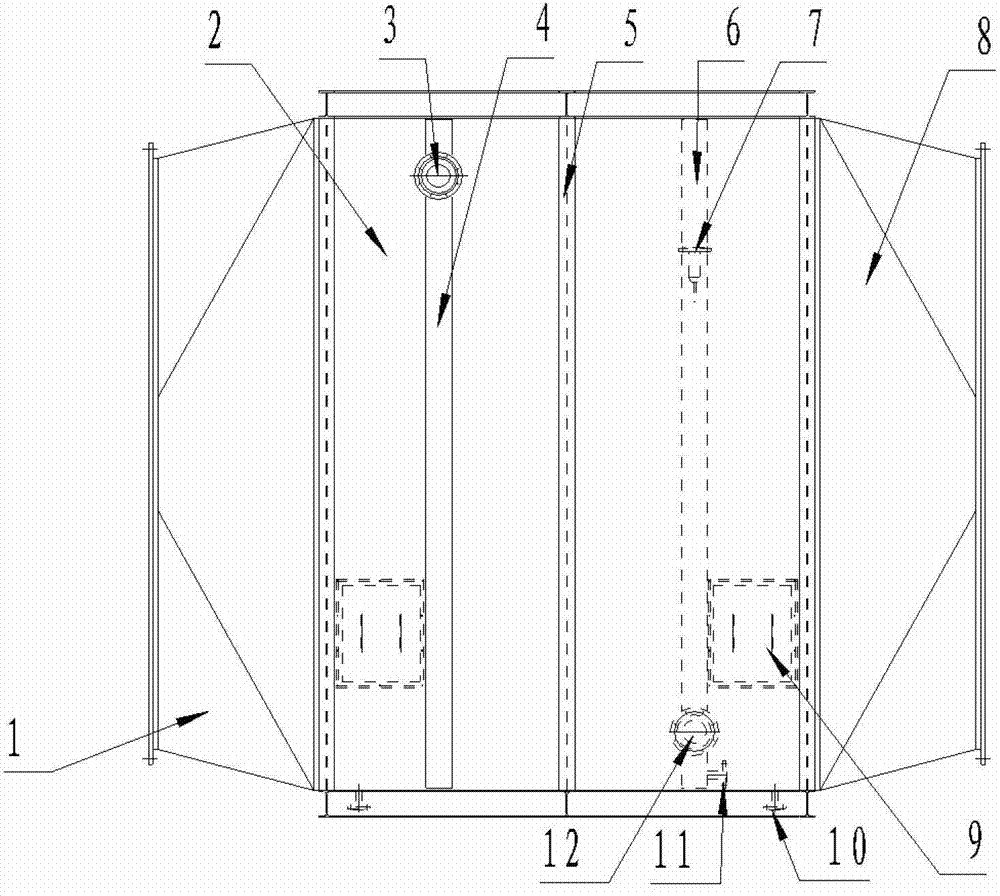

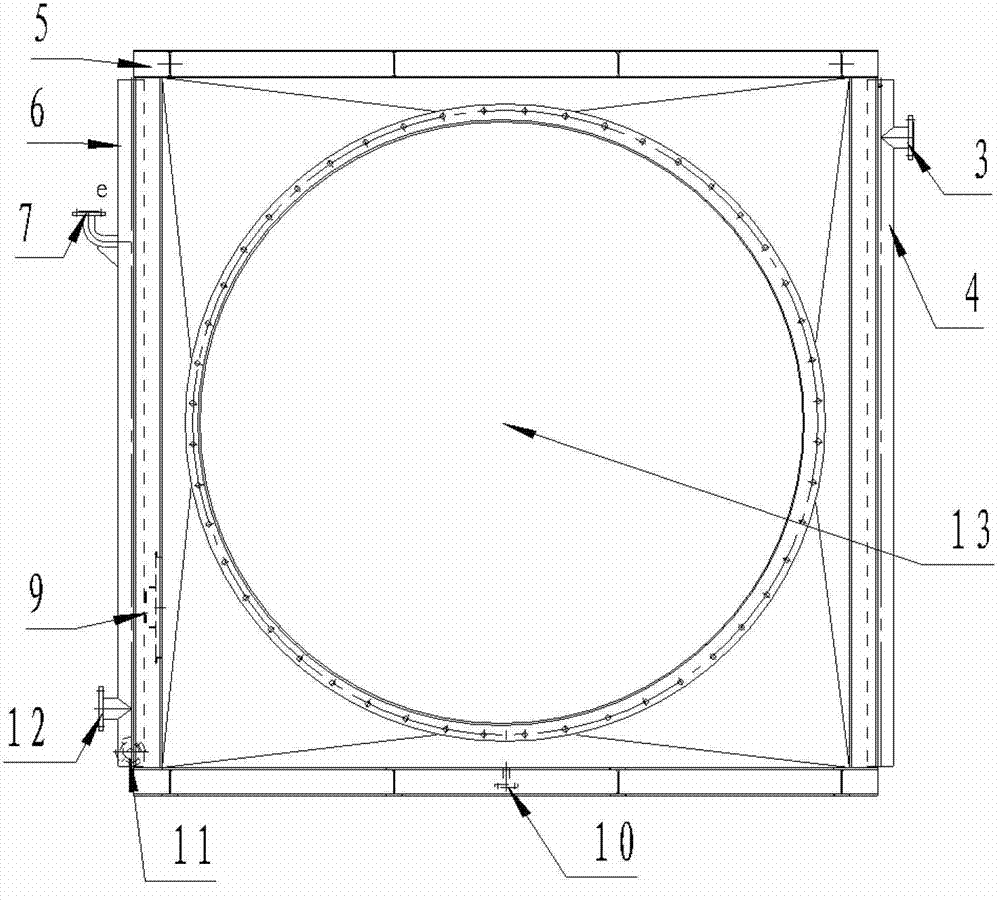

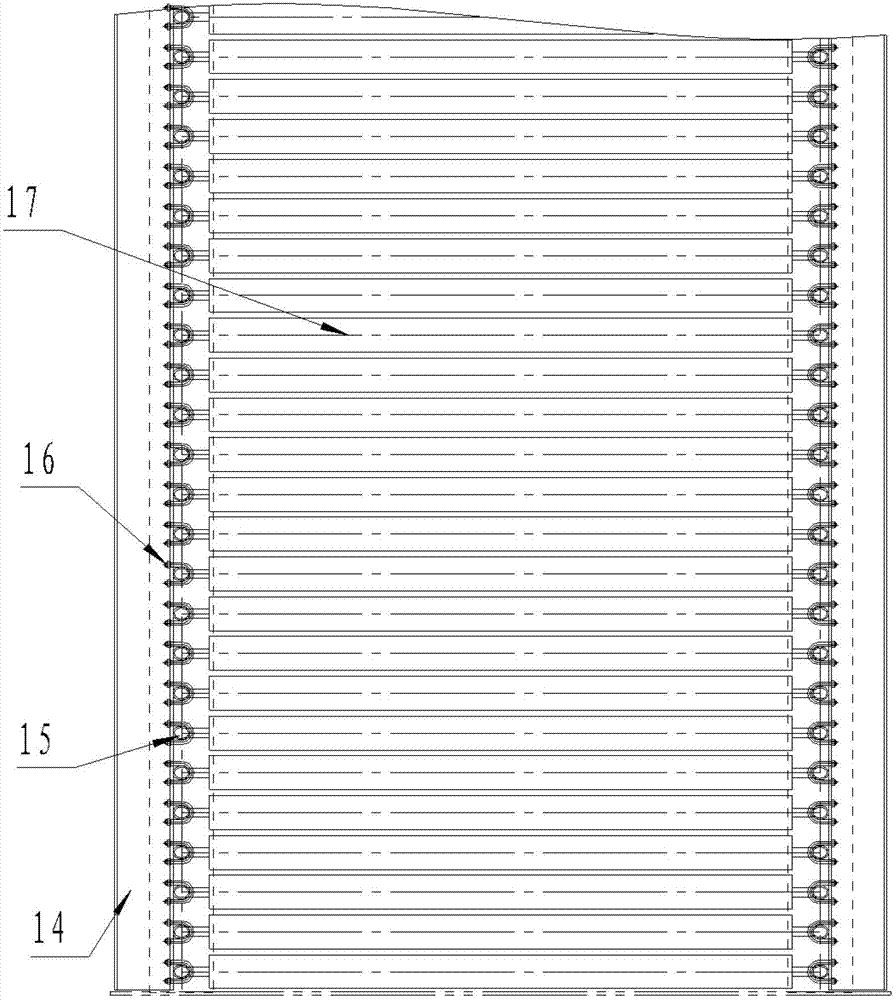

[0019] Example 1, a composite longitudinal finned tube flue gas waste heat exchanger, comprising a rectangular parallelepiped heat exchanger shell 2 with a flue gas inlet 1 and a flue gas outlet 8 respectively, the flue gas inlet and outlet are the same as The external flue gas pipe is a circular flange interface, and the shell is a square interface with a round sky and a square shape. The shell is equipped with a tube bundle 13 composed of longitudinal finned tubes, which is characterized in that: the inlet jellyfish tube 6 and the jellyfish outlet tube 4 are located outside the shell 2, the ends of the jellyfish inlet tube and the jellyfish outlet tube are closed, and the jellyfish tube is provided with The water inlet 12 is provided with the water outlet 3 on the jellyfish pipe. The longitudinal finned tube is a composite longitudinal finned tube 17 in which an inner steel pipe 19 is set inside an aluminum longitudinal finned tube 18 .

Embodiment 2

[0020] Example 2, a composite longitudinal finned tube flue gas waste heat exchanger, comprising a rectangular parallelepiped heat exchanger shell 2 with a flue gas inlet 1 and a flue gas outlet 8 respectively, the flue gas inlet and outlet are the same as The external flue gas pipe is a circular flange interface, and the shell is a square interface with a round sky and a square shape. The shell is equipped with a tube bundle 13 composed of longitudinal finned tubes, which is characterized in that: the inlet jellyfish tube 6 and the jellyfish outlet tube 4 are located outside the shell, the two ends of the jellyfish inlet tube and the jellyfish outlet tube are closed, and the inlet jellyfish tube is provided with an inlet A water outlet 12 is provided with a water outlet 3 on the jellyfish pipe. The bottom of the jellyfish tube is provided with a sewage outlet 11. The longitudinal finned tube is a composite longitudinal finned tube in which an inner steel pipe 19 is set inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com