Method for recovering surplus heat source energy by using flash evaporator

A technology of flash evaporator and heat source, which is applied in the field of using flash evaporator to recover excess heat source energy. It can solve the problems of ineffective use of heat, unreasonable recycling, and complex waste heat recovery system. It achieves no rotating parts, strong practicability, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

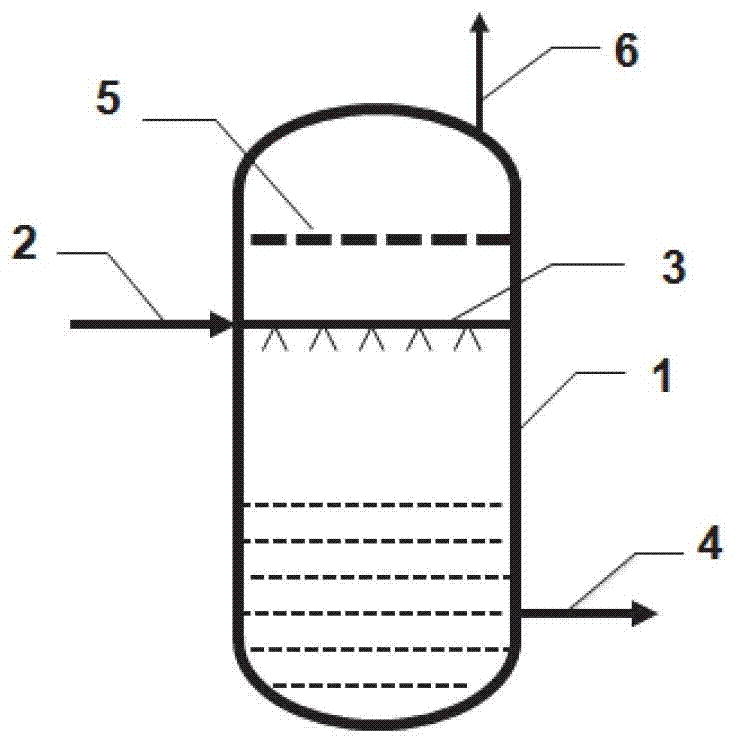

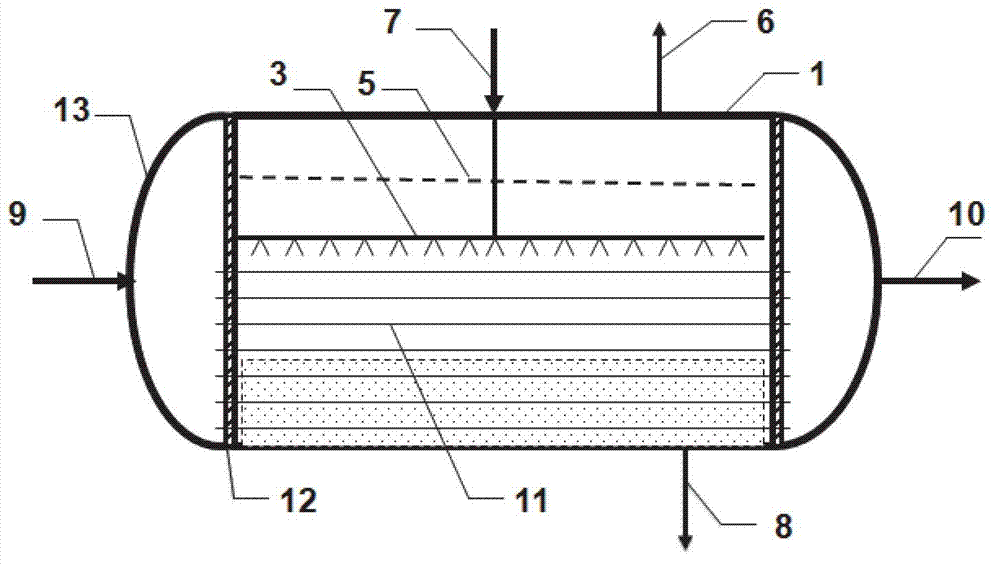

[0032] The specific implementation method is: the waste heat source B enters the heat exchange tube 11 at the lower part of the flasher from the waste heat source B inlet 9, releases heat to heat the waste heat source A liquid sprayed outside the heat exchange tube, and discharges it from the waste heat source B outlet 10 after releasing heat and cooling down Flash evaporator; the residual heat source A enters the spray pipe 3 from the inlet of the residual heat source A, and after forming droplets, due to expansion and pressure reduction, the liquid of the residual heat source A flashes a part of saturated steam under low pressure; the remaining residual heat source A liquid is in the form of fine liquid The form of droplets is sprayed on the surface of the heat exchange tube 11. After absorbing the heat of the waste heat source B in the heat transfer tube, a part of the liquid of the waste heat source A is vaporized into saturated steam, and the saturated steam is drawn out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com