Duplex pipe for gas draining and hole sealing by grouting

A gas drainage and grouting pipe technology, which is applied in the field of gas drainage pipes and coal mine gas drainage pipes, can solve the problems of inability to guarantee the depth and length of sealing holes, high cost of transfer and labor, and low gas drainage concentration. Achieve the effect of eliminating the loss of waste holes, improving the sealing effect, and simplifying process problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

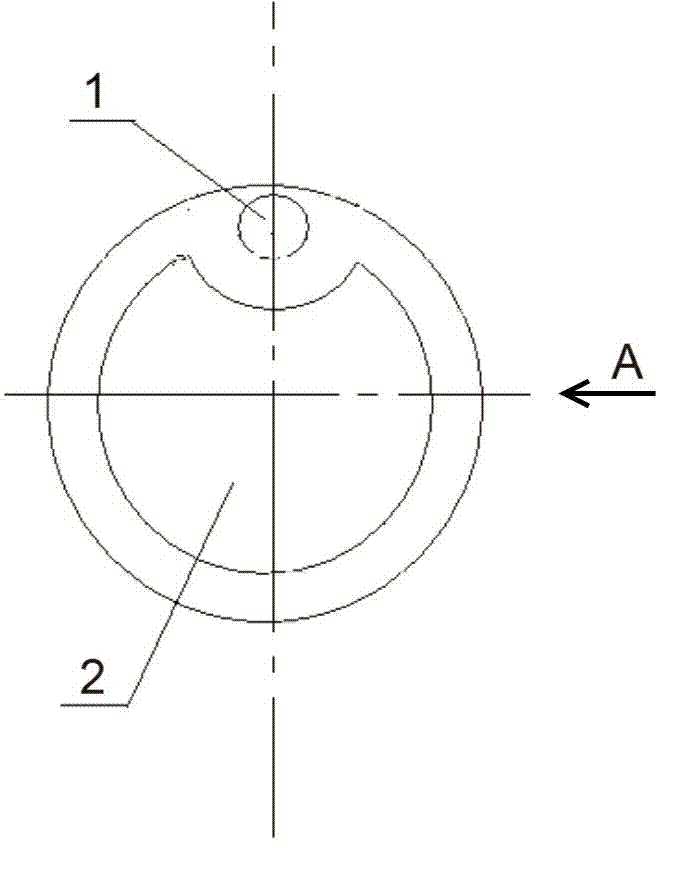

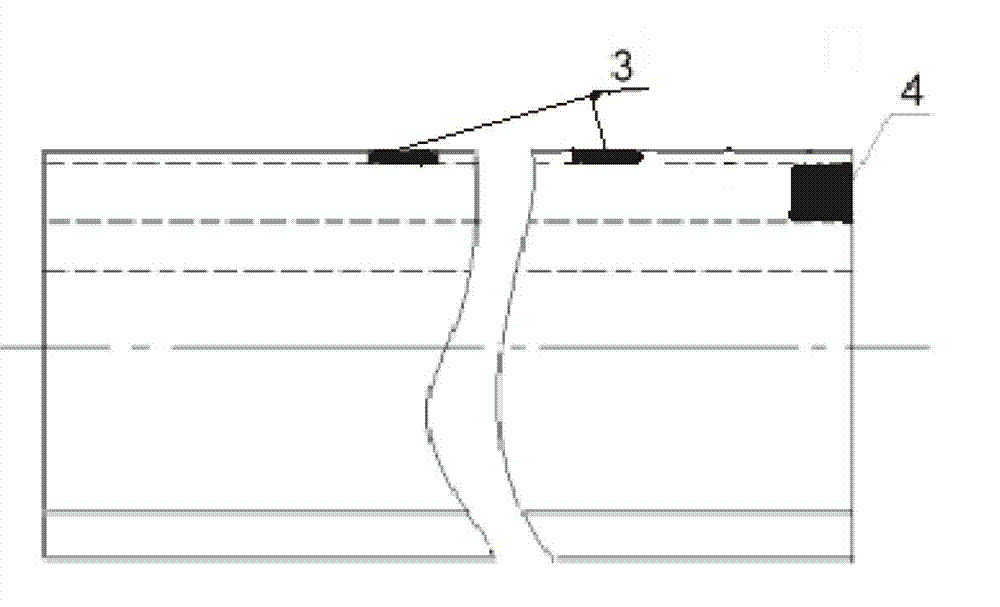

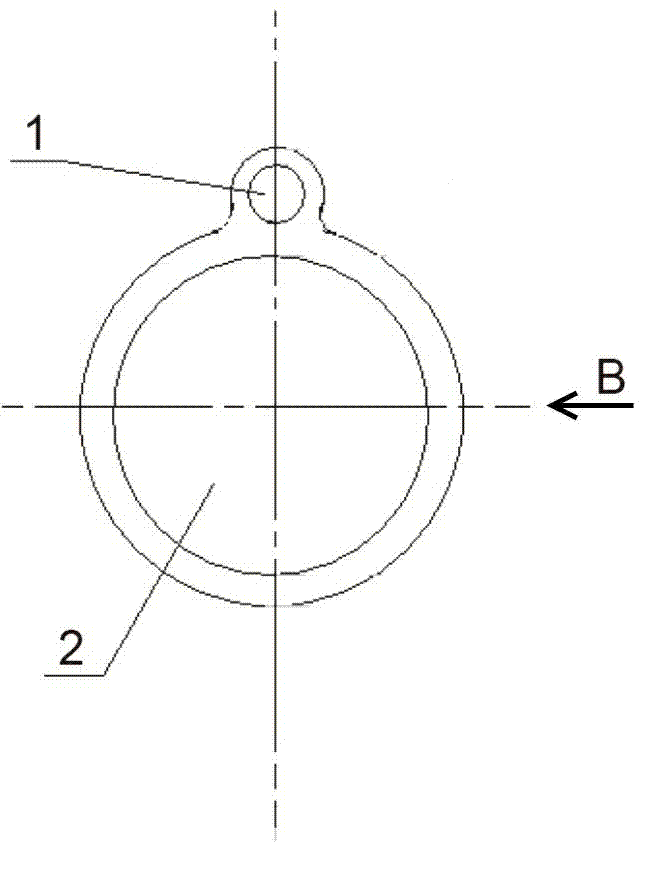

[0021] figure 1 It is one of the structural diagrams of the present invention (the grouting pipe is placed inside the gas drainage pipe), figure 2 for figure 1 A schematic diagram of the structure; image 3 It is the second structural diagram of the present invention (the grouting pipe is placed outside the gas drainage pipe), Figure 4 for image 3 Schematic diagram of the B-direction structure. The figure clearly shows a gas drainage and grouting sealing double pipe of the present invention, including a gas drainage pipe 2 and a grouting pipe 1, characterized in that: the gas drainage pipe 2 and the injection pipe The central axes of the grouting pipes 1 are arranged parallel to each other and in the same direction, and the gas drainage pipe 2 and the grouting pipe 1 are attached to each other and integrated into one body. figure 1 and figure 2 The structure shown is that the inner diameter of the gas drainage pipe 2 is larger than the outer diameter of the grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com