Magnetic powder clutch applying permanent magnet material

A technology of magnetic powder clutch and permanent magnet material, applied in the field of clutch, can solve the problems of increasing the rotational inertia of the engine flywheel, decreasing the acceleration power of the engine, complex structure and control system, etc., achieving simple structure, increasing effective area and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

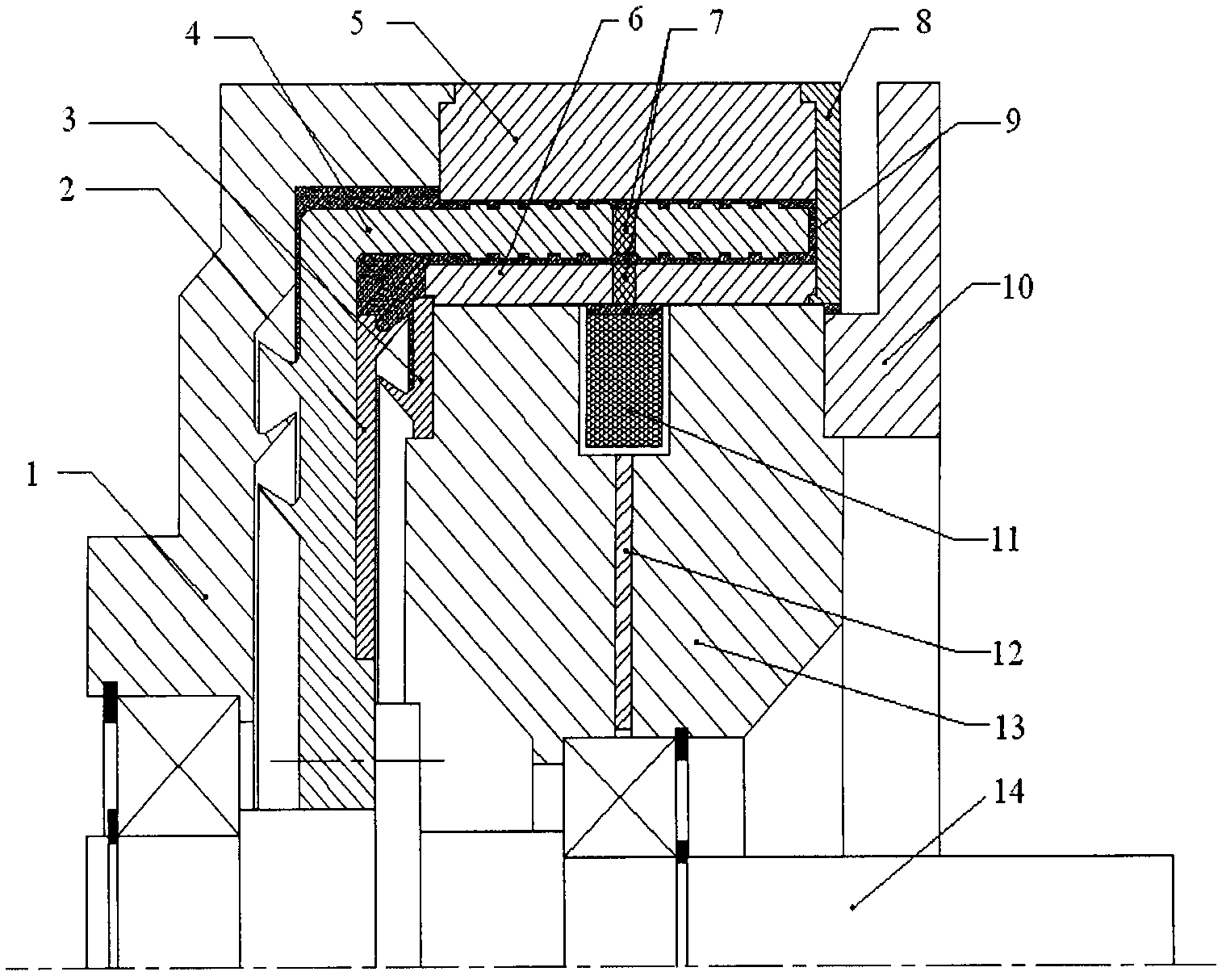

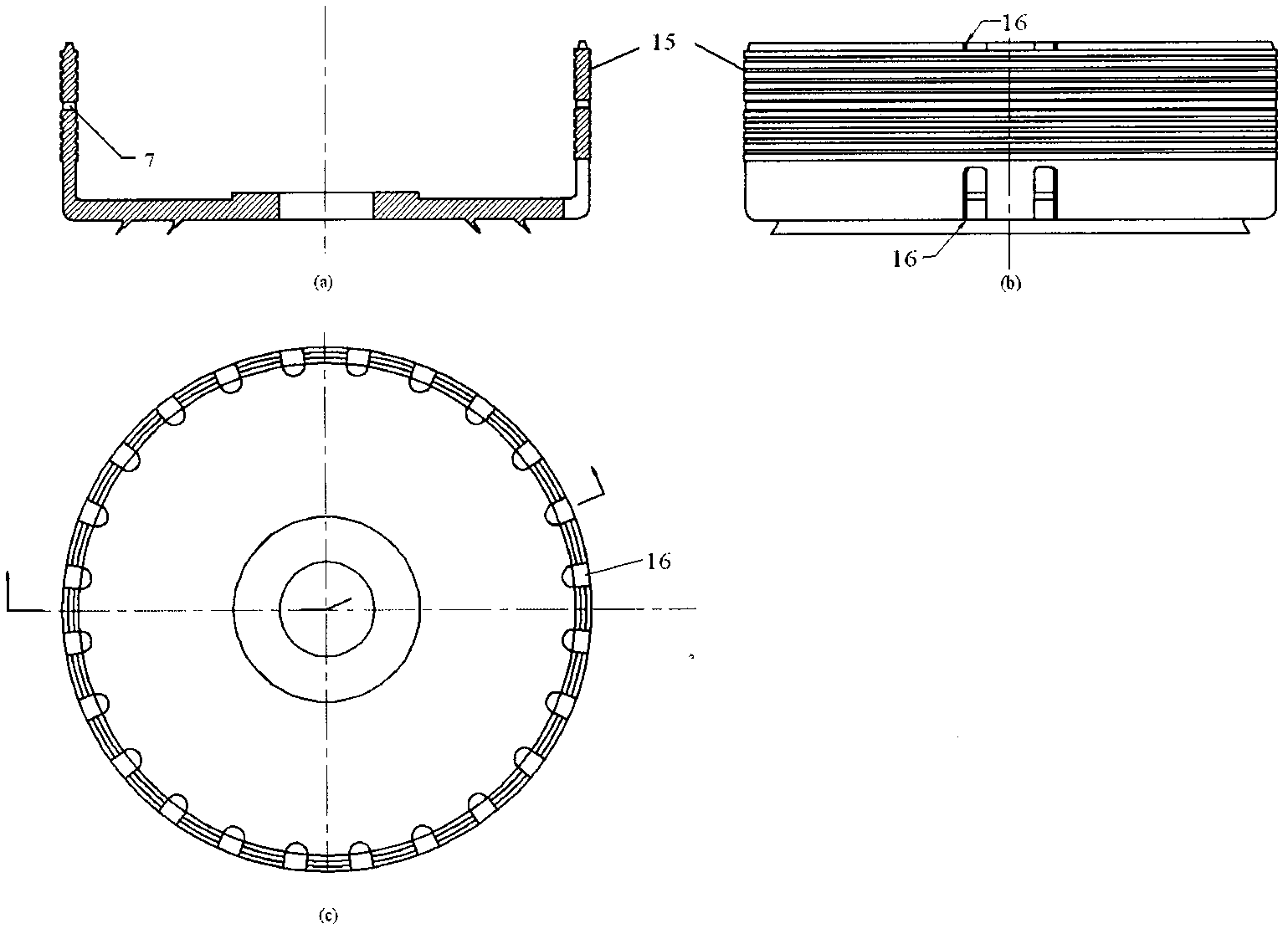

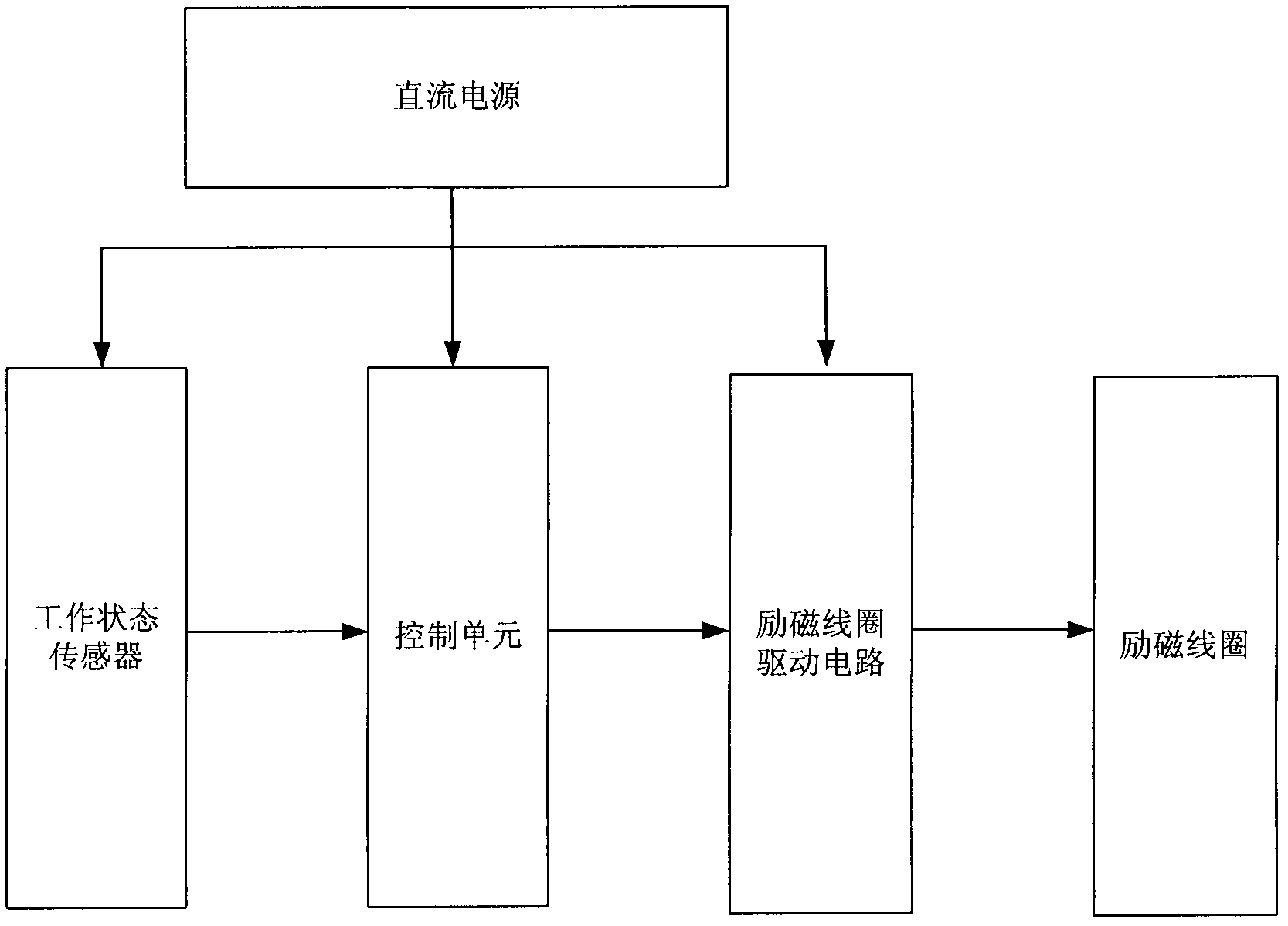

[0012] The present invention applies the magnetic powder clutch of permanent magnet material, figure 1 Its structural diagram shows that the permanent magnet 12 and the excitation coil 11 are embedded in the yoke 13 to form a permanent magnet-electromagnetic hybrid magnetic circuit structure. The permanent magnet 12 and the excitation coil 11 divide the yoke 13 into two parts in the axial direction. The permanent magnet 12 is located radially inside the excitation coil 11 . The yoke 13 is supported on the output shaft 14 through a bearing, and a magnetic powder stop ring 3 is installed on the end surface of the yoke 13 adjacent to the driven rotor 4 . The yoke 13 is connected with the flange 10, and the flange 10 is fixed on the base. The permanent magnet 12 can adopt NdFeB material.

[0013] The inner driving rotor 6 and the outer driving rotor 5 are connected as a whole through a connecting ring 8 to form a clutch driving rotor. The end cover 1 is connected with the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com