Cold flow test device for scaling linear plug type spray pipe carrier

A technology of plug nozzle and cold flow test, which is applied in jet propulsion devices, rocket engine devices, machines/engines, etc. It can solve problems such as over-expansion, pressure changes on the surface of plug cones, and pressure reduction on the wall of plug cones. Complete, wide range of research, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

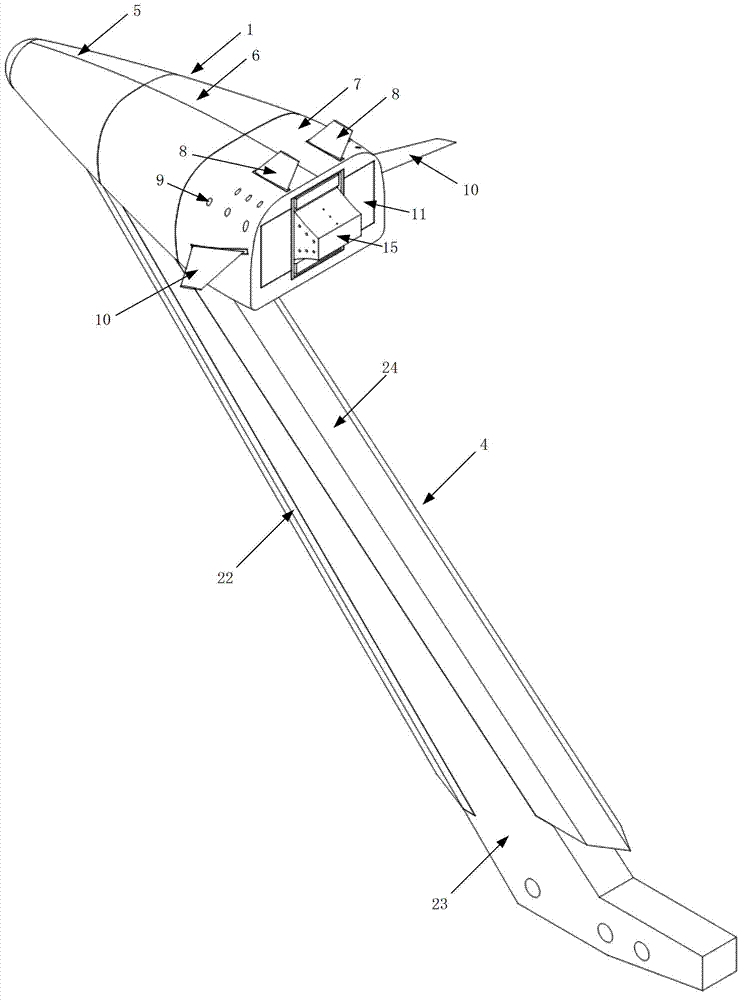

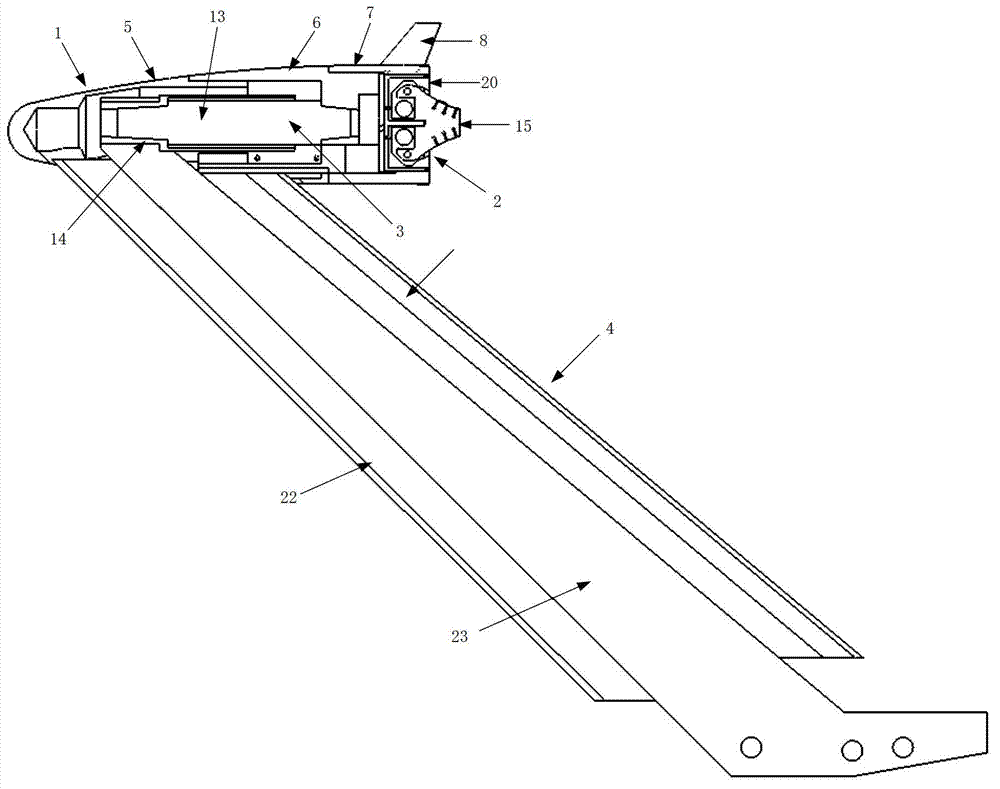

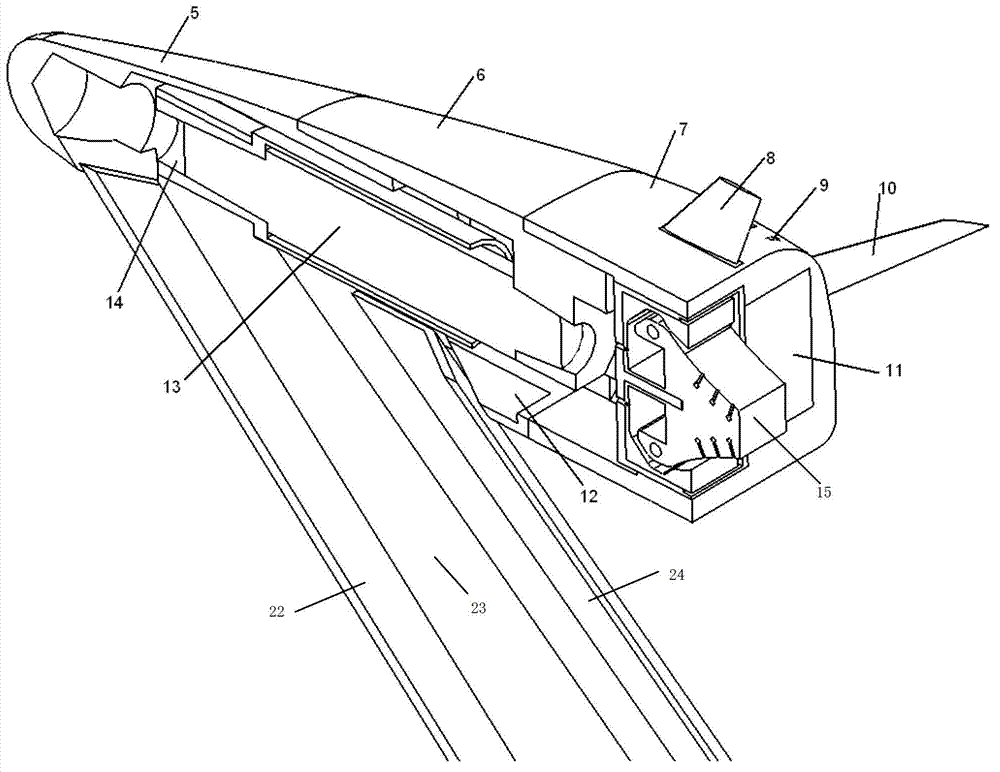

[0031] The invention is a cold flow test device for a scaled linear plug nozzle carrier, such as figure 1 and figure 2 As shown, it includes a lifting body assembly 1 , a plug nozzle assembly 2 , a force balance assembly 3 and a support assembly 4 .

[0032] Such as image 3 As shown, the lift body assembly 1 includes a lift body front portion 5, a lift body middle portion 6, a lift body rear portion 7, two vertical tails 8, two horizontal wings 10, twelve airfoil pins 9, two bottom covers plate 11 and two belly cover plates 12.

[0033] The front part 5 of the lifting body, the middle part 6 of the lifting body and the rear part 7 of the lifting body are all hollow structures, and the front part 5 of the lifting body, the middle part 6 of the lifting body and the rear part 7 of the lifting body are sequentially connected by screws to form the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com