Roller bit of rolling and sliding floating sleeve bearing

A technology of roller cone bits and floating sleeves, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of slow speed of floating sleeves, affecting the normal operation of floating sleeve bearings, and difficulty in lubricating medium, so as to improve the rotation accuracy and Lubricating ability, improved service life and work efficiency, and low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

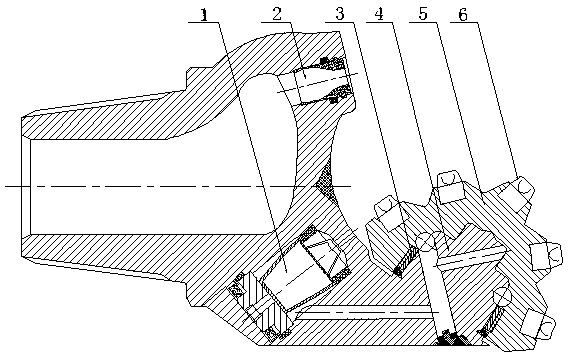

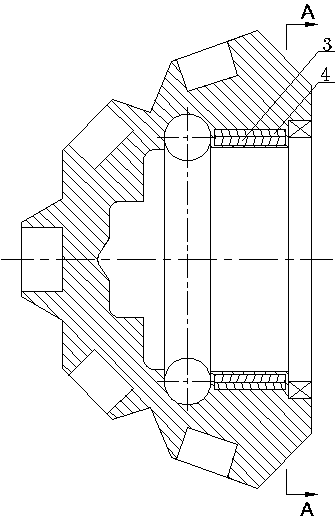

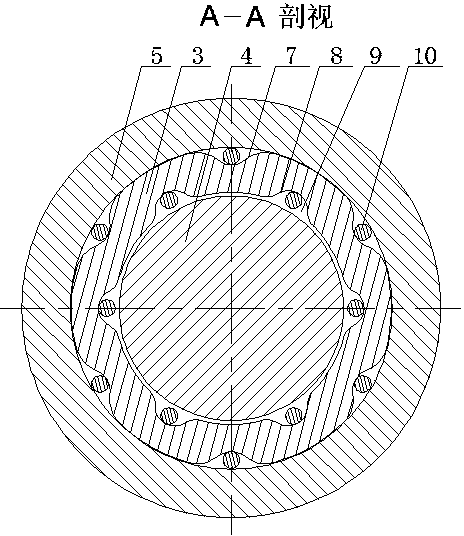

[0013] Such as figure 1 , figure 2 , image 3 As shown, a roller cone bit of a sliding floating sleeve bearing of the present invention mainly includes an oil storage chamber 1, a mud nozzle 2, claws 4, a cone 5, a sliding floating sleeve 3, and teeth 6. The floating sleeve The outer edge 7 is assembled in the inner hole of the cone, and its inner edge 8 is assembled on the large journal of the claw; the outer edge 7 of the floating sleeve is evenly arranged with 2-8 arc-shaped grooves 9, and the inner edge 8 of the floating sleeve is also evenly arranged with 2-8 arc-shaped grooves 11; the arc-shaped grooves 9 on the outer edge 7 of the floating sleeve and the arc-shaped grooves 11 on the inner edge 8 of the floating sleeve are alternately arranged along the circumferential direction; each arc-shaped groove (9, 11) is inlaid One needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com