Mounting method of floating floor or wallboard, and application thereof

An installation method and wall panel technology, which are applied in the directions of transportation and packaging, ship parts, ships, etc., can solve the problems of low comfort, poor shock absorption effect, and complicated process of luxury yachts, and achieve simple procedures, reduced thickness, enhanced The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

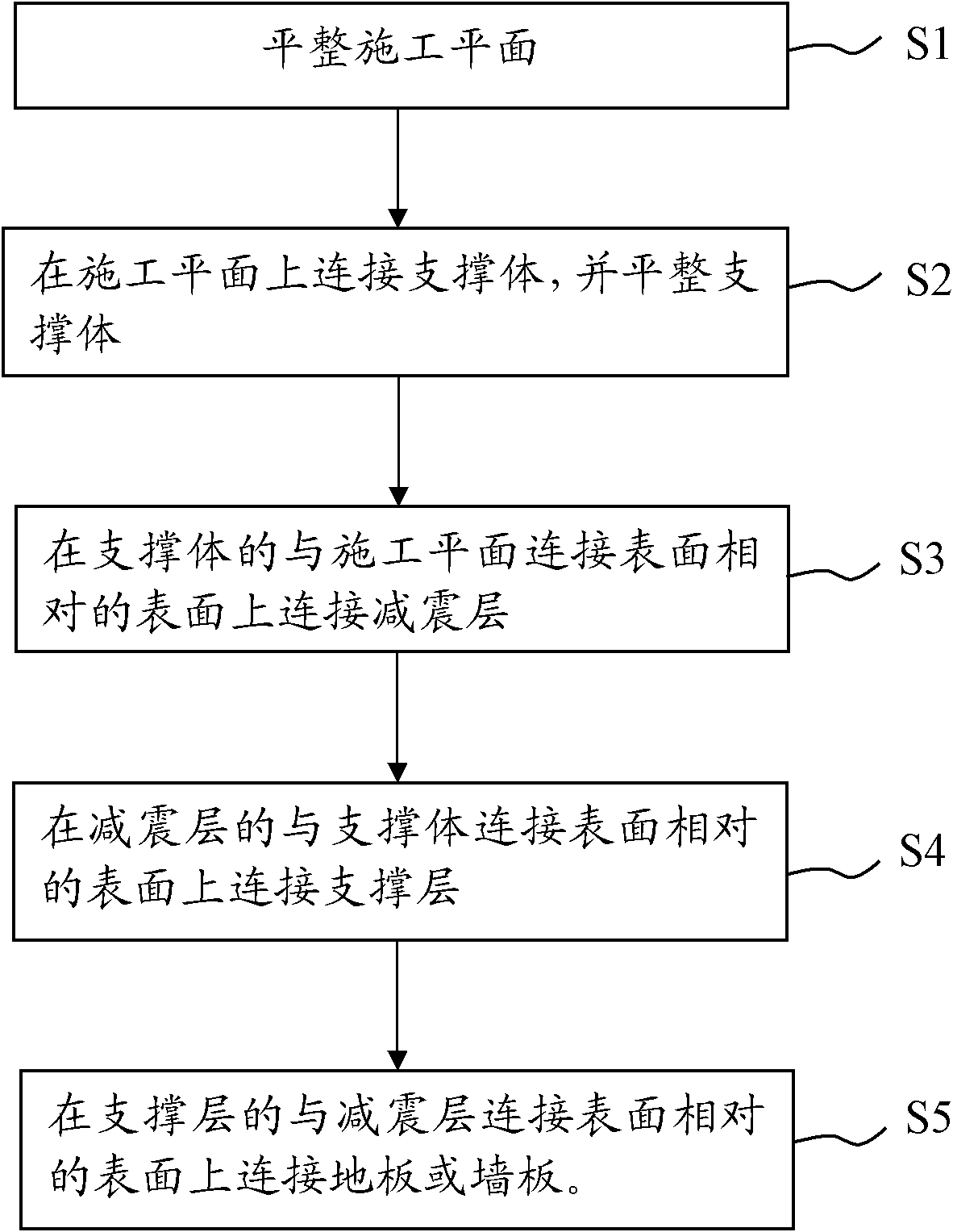

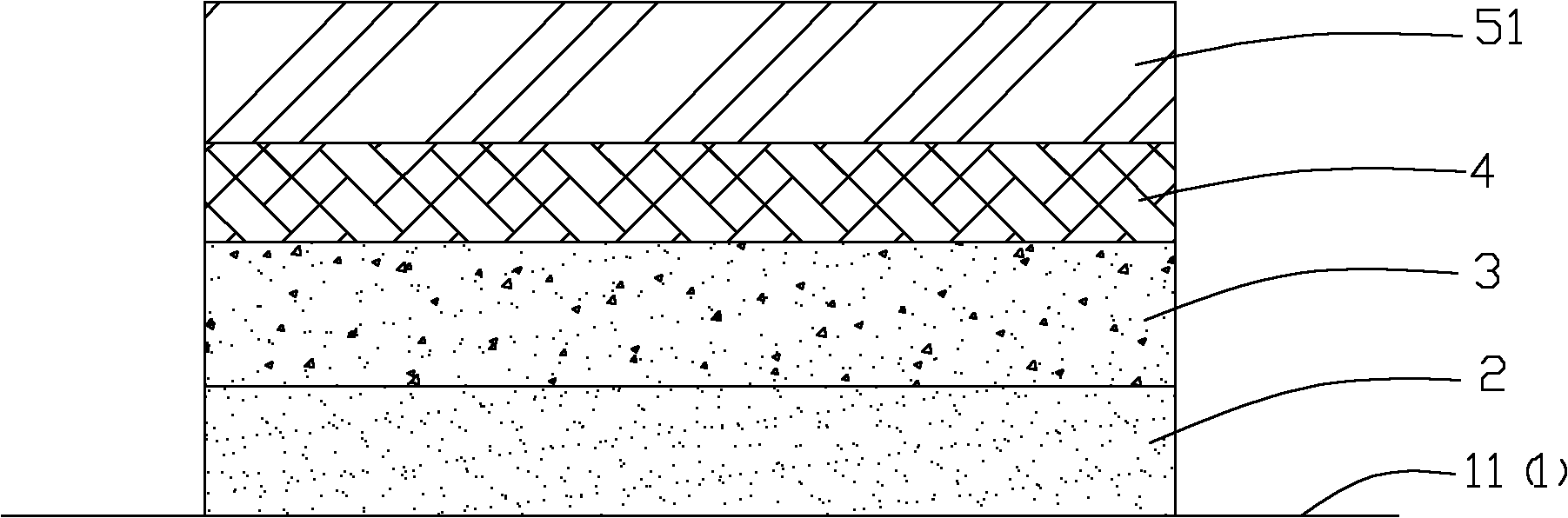

[0057] The installation method of the floating floor of a luxury yacht, the technical process of this method can be found in figure 1 , see also figure 2 As shown, the specific steps are as follows:

[0058] 1: Leveling the construction plane 1 is the deck of a luxury yacht 11:

[0059] 1.1: Select a reference point at the central area of deck 11;

[0060] 1.2: Set up an infrared laser level at the reference point, and emit rays around the reference point;

[0061] 1.3: Use the ruler to measure the vertical distance between the ray at the reference point and the deck 11, and select mark points on the deck 11 along the direction of each ray at intervals, and use the ruler again to measure the vertical distance between each mark point and the corresponding ray;

[0062] 1.4: Taking the vertical distance between the ray and the deck 11 as a reference, use the filling glue to fill and level the area centered on the marking point, so that the entire deck 11 is flat.

[0063]...

Embodiment 2

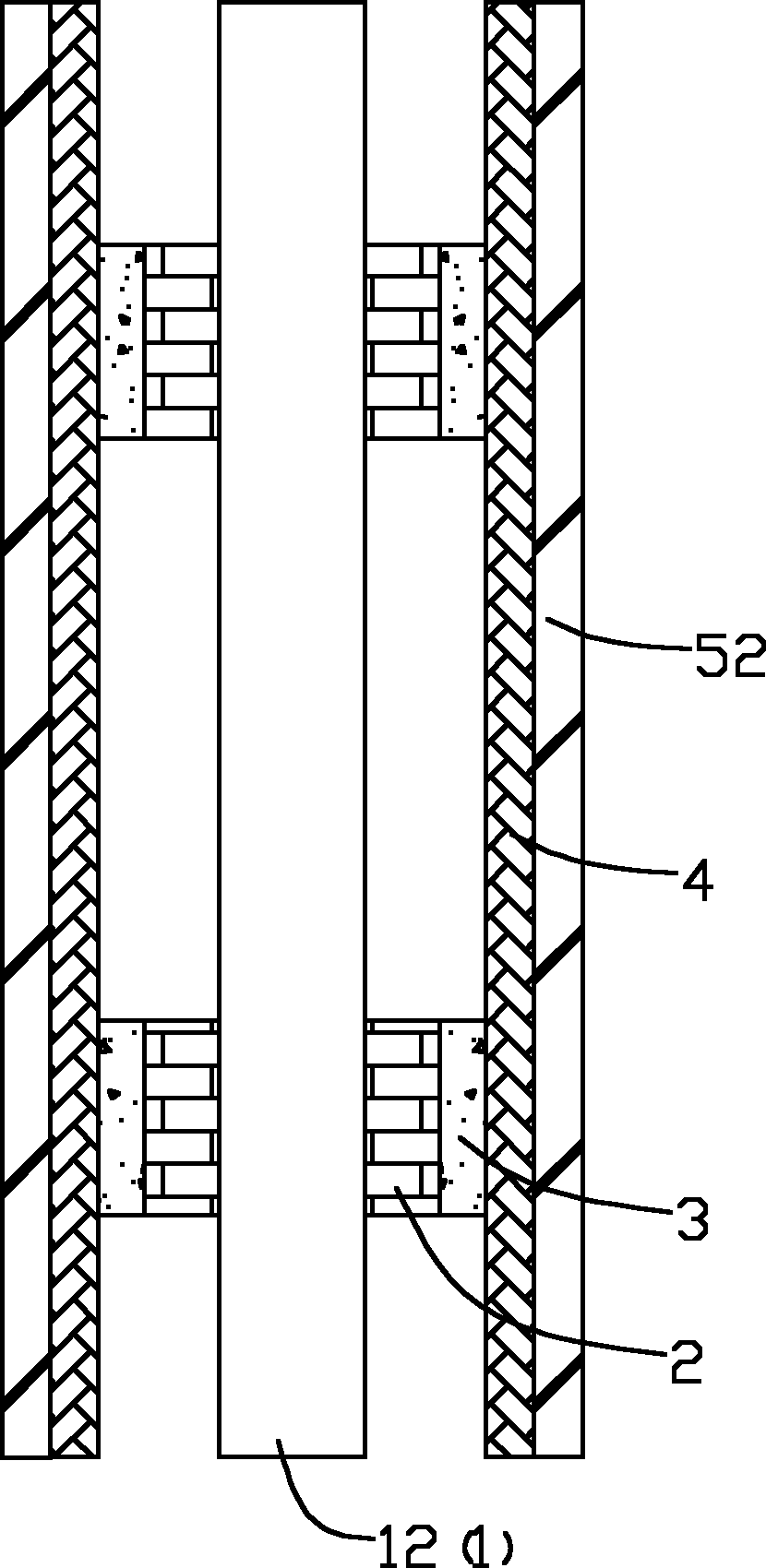

[0073] The installation method of the floating wall panels of luxury yachts, the technical process of this method can be found in figure 1 , see also image 3 As shown, the specific steps are as follows:

[0074] 1: Leveling the construction plane 1 is the compartment bulkhead of the luxury yacht 12:

[0075] 1.1: Select a reference point at the central area of the compartment bulkhead 12;

[0076] 1.2: Set up an infrared laser level at the reference point, and emit rays around the reference point;

[0077] 1.3: Use the ruler to measure the vertical distance between the ray at the reference point and the compartment bulkhead 12, and select marking points at intervals on the compartment bulkhead 12 along the direction of each ray, and then use the ruler to measure each mark point and the corresponding ray the vertical spacing between

[0078] 1.4: Taking the vertical distance between the ray and the compartment bulkhead 12 as a reference, use the filling glue to fill and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com