Cut-resistant core-spun yarn and application thereof

A cut-resistant and yarn-resistant technology, which is applied in yarn, textiles and papermaking, can solve the problems of easy contact with the human body, inflexible use, and the wearer's reluctance to wear it, achieving comfortable wearing, excellent cut-resistant quality, and improved safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

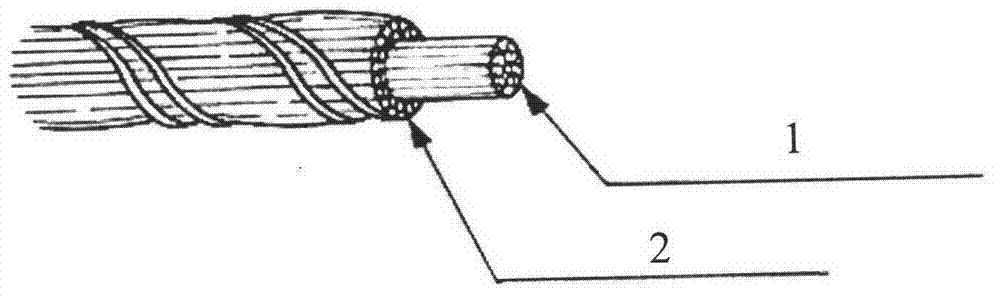

[0015] Such as figure 1 As shown, a cut-resistant core-spun yarn includes a core fiber 1 and an outer layer fiber 2, the outer layer fiber 2 wraps the core fiber 1 through a core-spun process, and the core fiber 1 is a glass filament, a basalt filament or a steel filament , or a covered, cored, twisted yarn containing one or more of the three fibers of glass filaments, basalt filaments and steel filaments; the outer fiber 2 is aramid staple fiber or Polyethylene staple fiber, or a mixed fiber (in any proportion) of aramid staple fiber and polyethylene staple fiber, or one or both of these two fibers containing aramid staple fiber and polyethylene staple fiber and Mixed fibers of other fibers.

[0016] The fineness of the glass filaments or basalt filaments is 5-150tex, the fineness of the steel filaments is 2-150um, and the glass filaments, basalt filaments or steel filaments have a twist of 20-1500 twists / m.

[0017] The core-spun process is a production process in which th...

Embodiment 2

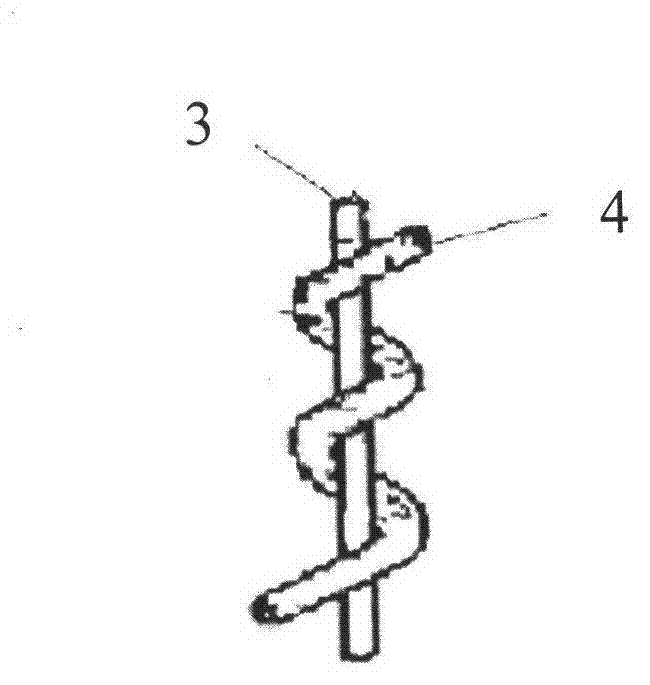

[0029] Such as figure 2 As shown, a cut-resistant yarn is a covering yarn 4 with the cut-resistant core-spun yarn 3 in Example 1 as the core. In addition to the characteristics of the core-spun yarn described in Example 1, the product also combines the diversity of covering processes to bring more style / performance advantages to the product.

[0030] The core core-spun yarn is the cut-resistant core-spun yarn described in Example 1.

[0031] The outer covering yarn is spun yarn or filament yarn with a thickness of 5-200tex, and the twist direction is S direction or Z direction.

[0032] The number of outer covering yarns is 1-5, and the twist directions are S direction or Z direction respectively.

Embodiment 3

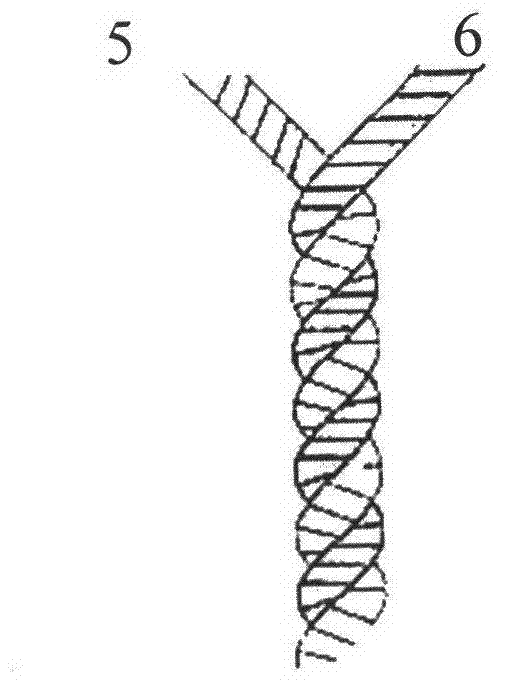

[0034] Such as image 3 As shown, a cut-resistant yarn is a twisted yarn comprising the cut-resistant corespun yarn described in Example 1. In addition to the characteristics of the core-spun yarn described in Example 1, the product combines the characteristics of the two-for-one twisting process and the performance of other parallel yarns, bringing more style / performance advantages to the product.

[0035] A yarn 5 is the cut-resistant core-spun yarn described in Example 1, and the twist direction is S-direction or Z-direction

[0036] B yarn 6 is the cut-resistant core-spun yarn described in Example 1, or other staple yarns or filament yarns, and the twist direction is the same as that of A yarn.

[0037] The twist direction of the plied yarn is opposite to that of A and B yarns, and the twist is 20-1500 twists / m.

[0038] The number of strands of single yarn is 2-6. The cut-resistant core-spun yarns described in Example 1 can be 1-6 of them, and each can be different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com