Buffer block rubber composition for automobile

A rubber composition and buffer block technology are applied in the fields of buffer rubber products and automotive buffer block rubber thick products, which can solve the problems of low compression permanent deformation, loss of high elasticity of rubber, failure of rubber buffer blocks, etc. Rubber hardness, the effect of reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

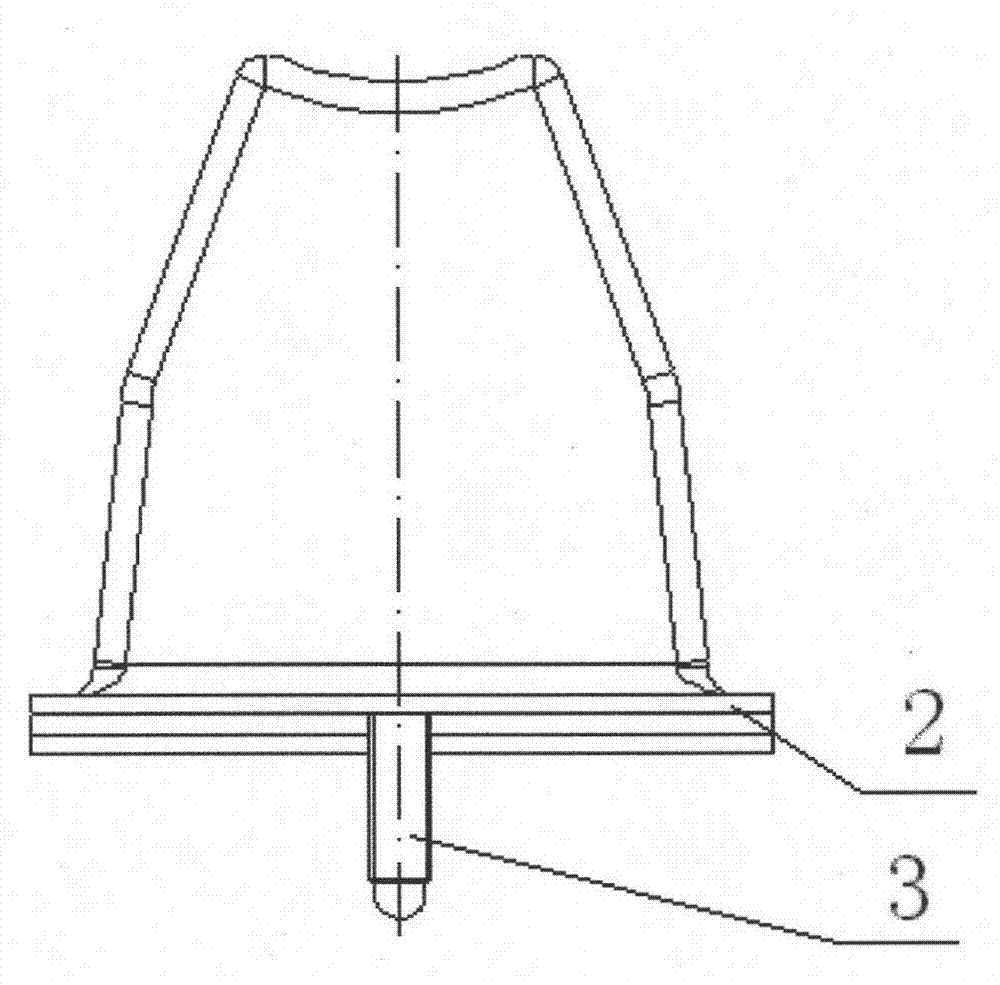

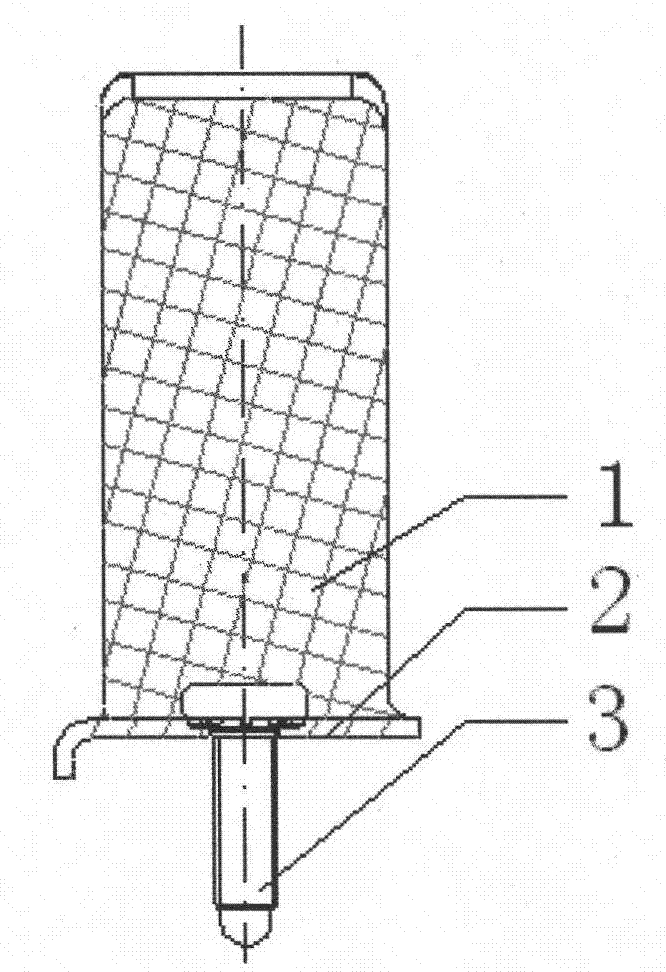

Image

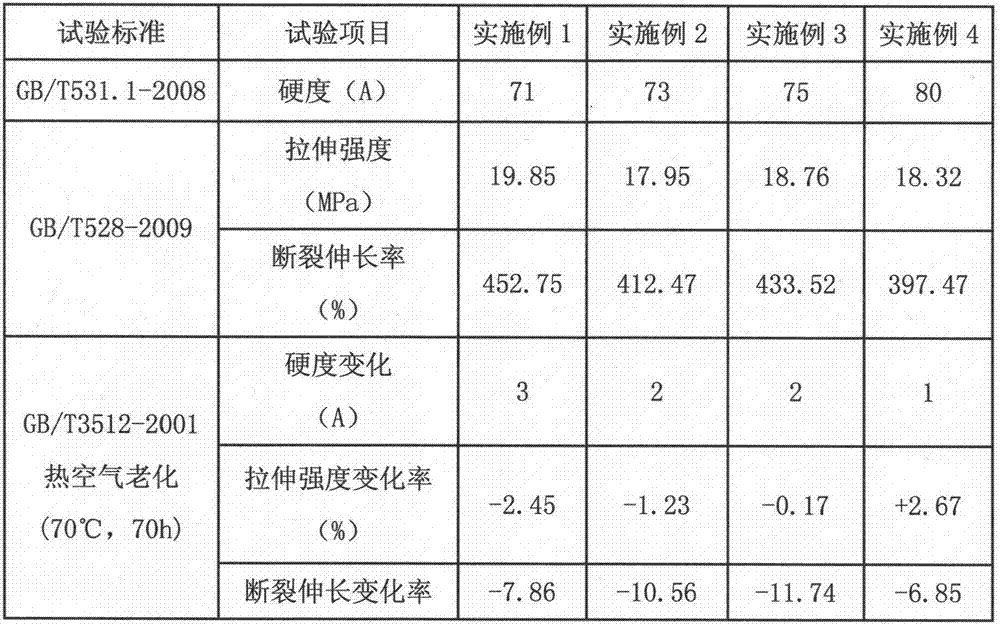

Examples

Embodiment 1

[0038] An automobile buffer block rubber composition is prepared from the following raw materials in parts by weight:

[0039] SVR-3L 60 copies;

[0040] BR9000 40 copies;

[0041] 2 parts of N-isopropyl-N'-phenyl-p-phenylenediamine (anti-aging agent 4010NA);

[0042] 2 parts of 2,2,4-trimethyl-1,2-quinoline dichloride polymer (anti-aging agent RD);

[0043] Microcrystalline paraffin 1900 2 parts;

[0044] 5 parts of naphthenic oil;

[0045] N-550 50 copies;

[0046] 5 copies of WB212;

[0047] 10 parts of zinc methacrylate;

[0049] 3 parts of stearic acid;

[0050] 2 parts of sulfur;

[0051] 1.6 parts of N-tert-butyl-2-benzothiazole sulfenamide (accelerator NS);

[0052] Zinc dibutyl dithiocarbamate (accelerator BZ) 0.4 part.

[0053] The preparation process is:

[0054] (1) One-stage mixing: raise the temperature of the mixer to 140±10°C, put SVR-3L, BR9000 and zinc methacrylate into the mixer for mixing, and the mixing time is 5...

Embodiment 2

[0059] An automobile buffer block rubber composition is prepared from the following raw materials in parts by weight:

[0060] SVR-3L 70 copies;

[0061] BR9000 30 copies;

[0062] 5 parts of zinc oxide;

[0063] 1 part of stearic acid;

[0064] 2.5 parts of 2,2,4-trimethyl-1,2-quinoline dichloride polymer (anti-aging agent RD);

[0065] 1.5 parts of N-isopropyl-N'-phenyl-p-phenylenediamine (anti-aging agent 4010NA);

[0066] Microcrystalline paraffin 1900 4 parts;

[0067] 20 parts of zinc methacrylate;

[0068] 3 copies of WB212;

[0069] 3 parts of naphthenic oil;

[0070] N-550 30 copies;

[0071] 1.7 parts of N-tert-butyl-2-benzothiazole sulfenamide (accelerator NS);

[0072] 0.3 part of zinc dibutyl dithiocarbamate (accelerator BZ);

[0073] Sulfur 1.5 parts.

[0074] The preparation process is the same as in Example 1.

Embodiment 3

[0076] An automobile buffer block rubber composition is prepared from the following raw materials in parts by weight:

[0077] SVR-3L 60 copies;

[0078] BR9000 40 copies;

[0079] 6 parts of zinc oxide;

[0080] 2 parts of stearic acid;

[0081] 1.5 parts of 2,2,4-trimethyl-1,2-quinoline dichloride polymer (anti-aging agent RD);

[0082] 2.5 parts of N-isopropyl-N'-phenyl-p-phenylenediamine (anti-aging agent 4010NA);

[0083] Microcrystalline paraffin 1900 3 parts;

[0084] 15 parts of zinc methacrylate;

[0085] 4 copies of WB212;

[0086] 4 parts of naphthenic oil;

[0087] N-550 40 copies;

[0088] 1.8 parts of N-tert-butyl-2-benzothiazole sulfenamide (accelerator NS);

[0089] 0.2 part of zinc dibutyl dithiocarbamate (accelerator BZ);

[0090] Sulfur 2.5 parts.

[0091] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com