Thermal absorption and insulation composite lining cloth

A thermal insulation composite and interlining technology, applied in the field of thermal insulation materials, can solve the problems of color difference, unfavorable product quality stability, etc., and achieve the effect of increasing the peripheral temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

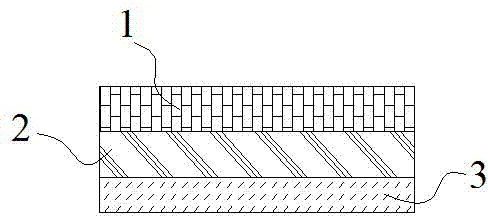

[0013] Heat-absorbing and heat-preserving composite interlining cloth, including an Oxford cloth layer 3, on which a manganese dioxide layer 2 and a carbon black layer 1 are sequentially arranged, and a tetrafluoroethylene layer is arranged between the manganese dioxide layer 2 and the carbon black layer 1 . The thickness of the tetrafluoroethylene layer is 1mm. The outer surface of the carbon black layer 1 is provided with pits, and the pit density is 200 / m 2 . The heat-absorbing and heat-preserving composite interlining can actively absorb solar energy, increase the peripheral temperature of the storage tank, indirectly increase the temperature of the dye in the storage tank, and make it within a suitable storage temperature range. On a sunny day at -10°C, the temperature of the dye in the dye storage tank wrapped by the thermal insulation composite interlining is kept at 3-4°C.

[0014]

Embodiment 2

[0016] Heat-absorbing and heat-preserving composite interlining cloth, including an Oxford cloth layer 3, on which a manganese dioxide layer 2 and a carbon black layer 1 are sequentially arranged, and a tetrafluoroethylene layer is arranged between the manganese dioxide layer 2 and the carbon black layer 1 . The thickness of the tetrafluoroethylene layer is 2mm. The outer surface of the carbon black layer 1 is provided with pits, and the pit density is 150 / m 2 . The heat-absorbing and heat-preserving composite interlining can actively absorb solar energy, increase the peripheral temperature of the storage tank, indirectly increase the temperature of the dye in the storage tank, and make it within a suitable storage temperature range. On a sunny day at -5°C, the temperature of the dye in the dye storage tank wrapped by the thermal insulation composite interlining is kept at about 2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com