Horizontal-type fast assembling platform for H profile steel

An H-beam and platform technology, applied in the fields of construction and machinery, can solve the problems of inability to cope with oversized H-beams, poor safety and unsuitability, and achieve the effect of shortening the construction period, high work efficiency, and convenient overall disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

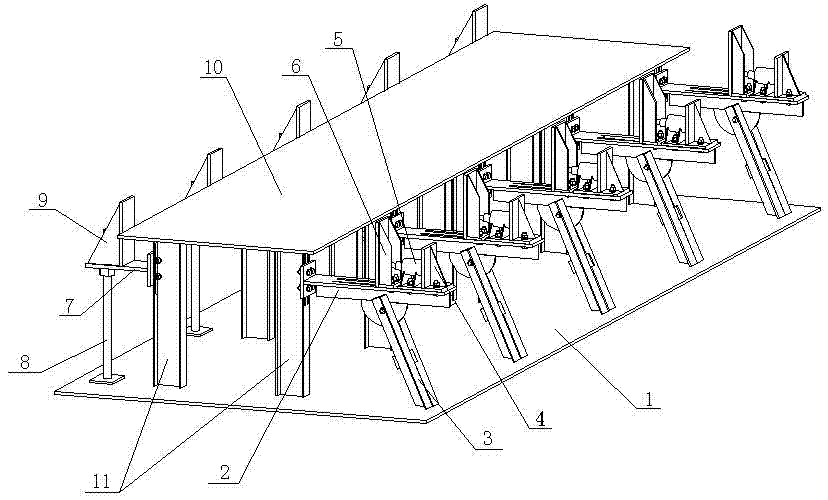

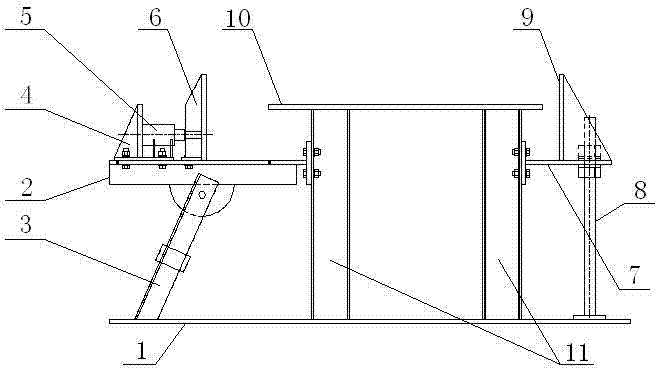

[0026] like figure 1 , figure 2 As shown, this embodiment includes a bottom plate 1 and a main platform structure for supporting the H-shaped steel web and an adjustment support structure for adjusting the position of the H-shaped steel flange plate arranged on the bottom plate 1. The adjustment support structure includes a positioning adjustment support The device and the pre-adjustment support device, the positioning adjustment support device and the pre-adjustment support device are respectively located on both sides of the main platform structure.

[0027] The main platform structure of this embodiment includes a supporting platform 10 and platform legs 11 for fixing the supporting platform 10, and the supporting platform 10 is used for horizontally laying the web of the H-shaped steel.

[0028] The positioning adjustment support device of this embodiment includes several positioning adjustment support units. The positioning adjustment support unit includes a sliding pla...

Embodiment 2

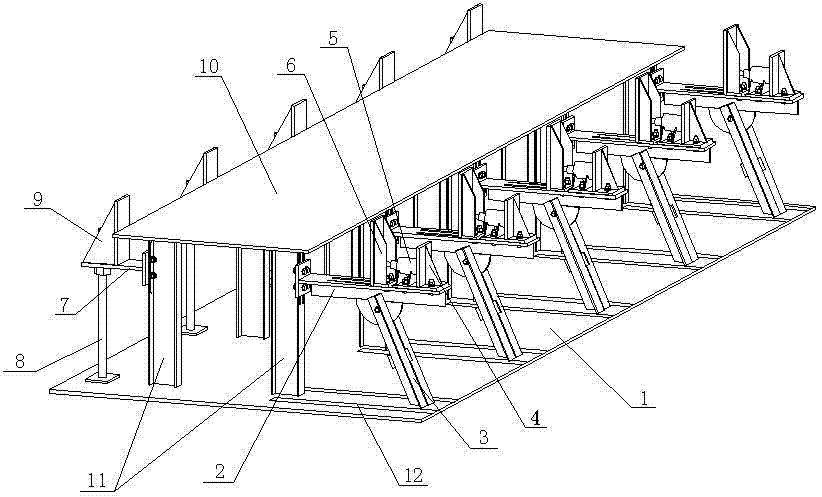

[0035] like image 3 , Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the bottom plate 1 of this embodiment is provided with a guide rail 12, the lower end of the support rod 3 is arranged on the guide rail 12, and the lower end of the support rod 3 can be placed on the guide rail 12. Free movement makes the adjustment of support rod 3 more labor-saving; after adjusting the position of support rod 3, the lower end of support rod 3 is fixed on the guide rail 12 by locking device, and general bolts, lock pins, etc. can realize locking.

[0036] The working principle of embodiment 2 is: as Figure 5 As shown, first the steel plate used as the H-shaped steel flange plate is placed on the support plate 7 through the lifting device, and the steel plate is located between the baffle plate 9 and the platform leg 11, and then the steel plate used as the H-shaped steel web is passed through The lifting device is placed flat on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com