Auxiliary mechanism on disk slitting machine

An auxiliary mechanism and slitting technology, which is applied to the attachments of shearing machines, shearing machine equipment, shearing devices, etc., can solve the problem of short service life of the blades of the disc slitting machine, discoloration of the end face of the product, and poor quality of the edge of the strip. and other problems, to achieve the effect of solving the discoloration of the copper strip end face, making it simple, and reducing the number of grindings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in conjunction with the accompanying drawings.

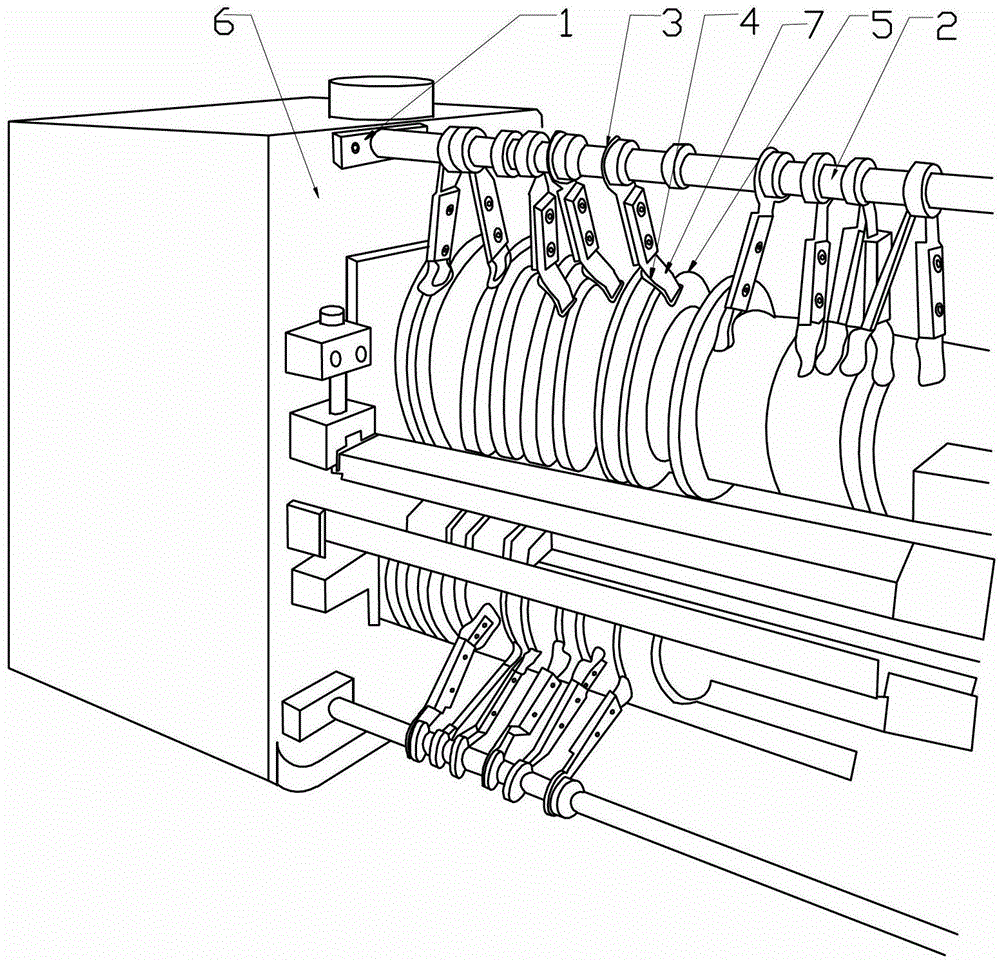

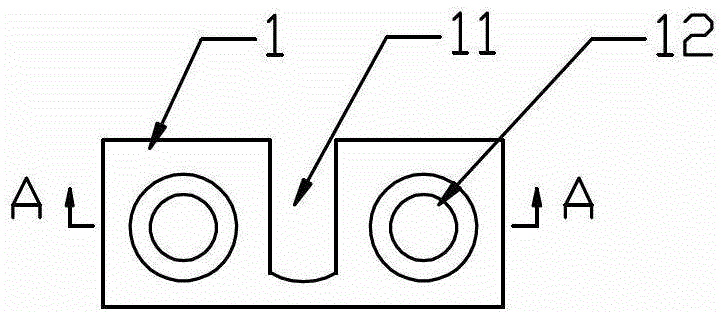

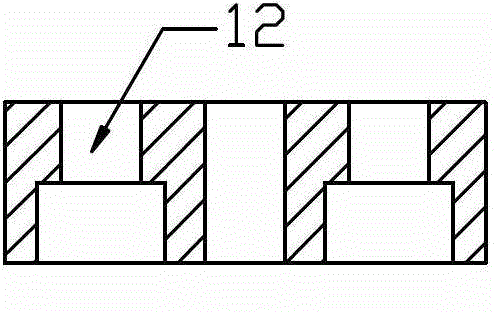

[0038] Such as figure 1 As shown, a guide shaft 2 is installed on the knife seat 6 of the disc slitting unit through two oppositely installed fixed seats 1, and a slip ring assembly 3 is installed on the guide shaft 2, forming a direction extending toward the blades in the disc blade group. The bracket composed of guide shaft 2 and slip ring assembly 3 is provided with an elastic element composed of elastic piece 7 and a flexible moisture-absorbing material composed of wool felt pad 4 is fixed. The elastic piece 7 is attached to the felt pad 4, and the elastic piece The direction of elasticity of 7 is to make the felt pad 4 lean against the cutting end face of the blade 5 (comprising the outer end face and the side of the cutting corner), so that when the disc shears are working, the felt pad can always be attached to the blade to wipe the blade and remove it. Remove the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com