Device for removing impurities in preserved radish strip by burning

A kind of radish strips, overfire technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems such as difficult to remove small debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

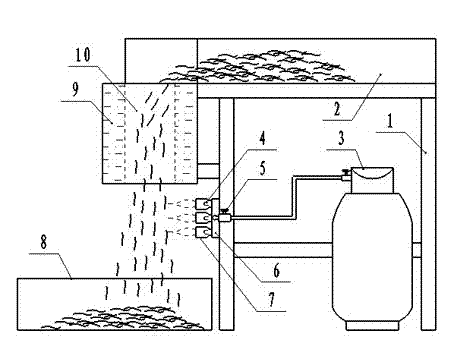

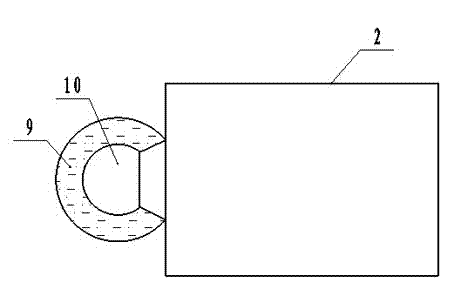

[0008] Example: as attached figure 1 , attached figure 2 As shown, a radish strip overfire impurity removal device has a workbench 1 in a square shape, a material pan 2 is arranged on the workbench 1, a material receiving tray 8 is placed under the workbench 1, and one end of the workbench 1 is placed on the material tray 2 , a blanking channel 10 is provided, and beside the lower end of the blanking channel 10, a fire spraying device is installed. The fire head 4 and the fire spray head 4 are set in the outer jacket 7; a cooling water jacket 9 is installed around the feeding channel 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com