Manufacturing method for heavy-copper printed circuit boards

A technology for printed circuit boards and manufacturing methods, which is applied in the direction of printed circuits, printed circuit manufacturing, and electrical components, and can solve the problems of low reliability of HASL, explosion of boards, and reduction of HASL costs, so as to reduce the amount of tin used , cost reduction and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

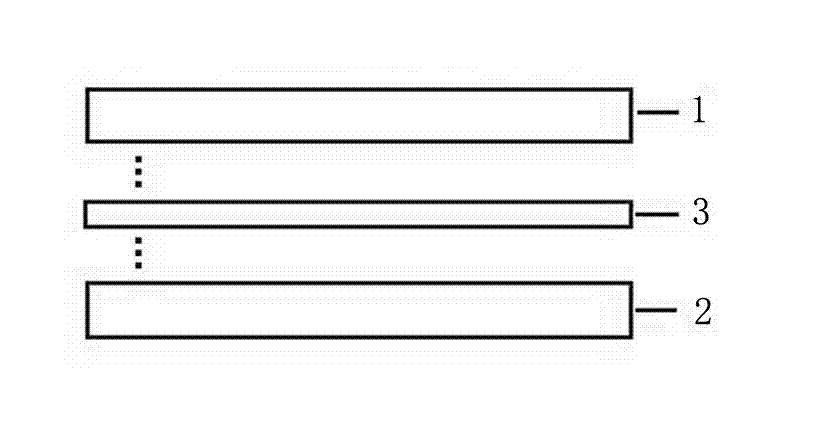

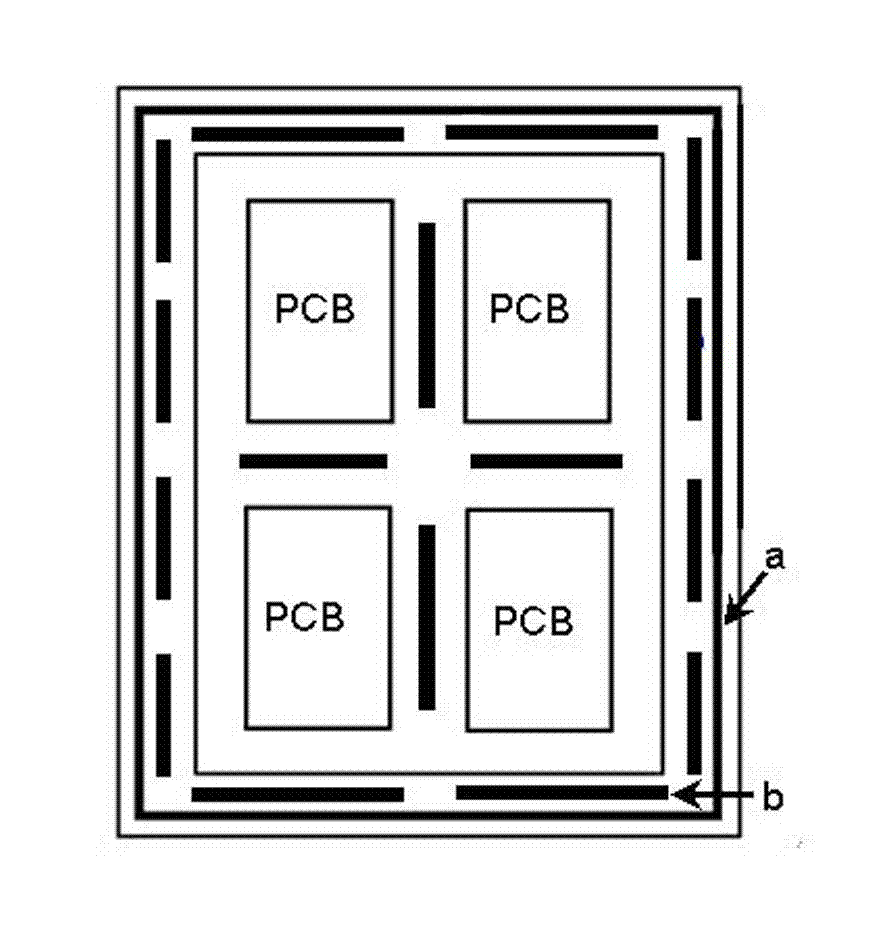

[0032] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 2 As shown, a thick copper printed circuit board includes at least two inner substrates, that is, a first inner substrate 1 and a second inner substrate 2, and an adhesive sheet 3 is arranged between the two inner substrates. Such as image 3 As shown, there is a hollow area b between the non-effective graphic area or the typesetting spacing on the edge of the board.

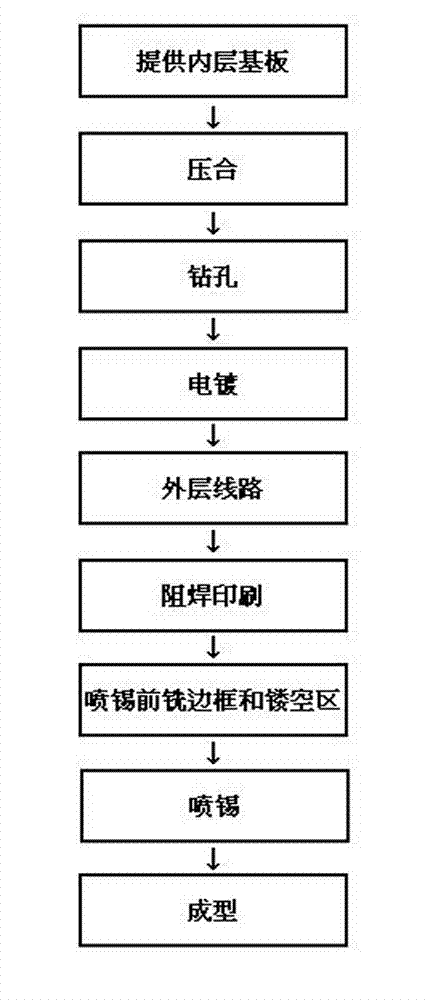

[0033] Such as Figure 1 to Figure 3 Shown, a kind of manufacturing method of thick copper type printed circuit board comprises the following steps:

[0034] (1) Provide inner substrates: First, provide at least two inner substrates as required, namely the first inner substrate 1 and the second inner substrate 2, at least one inner substrate with a copper thickness ≥ 3oz, in each inner substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com