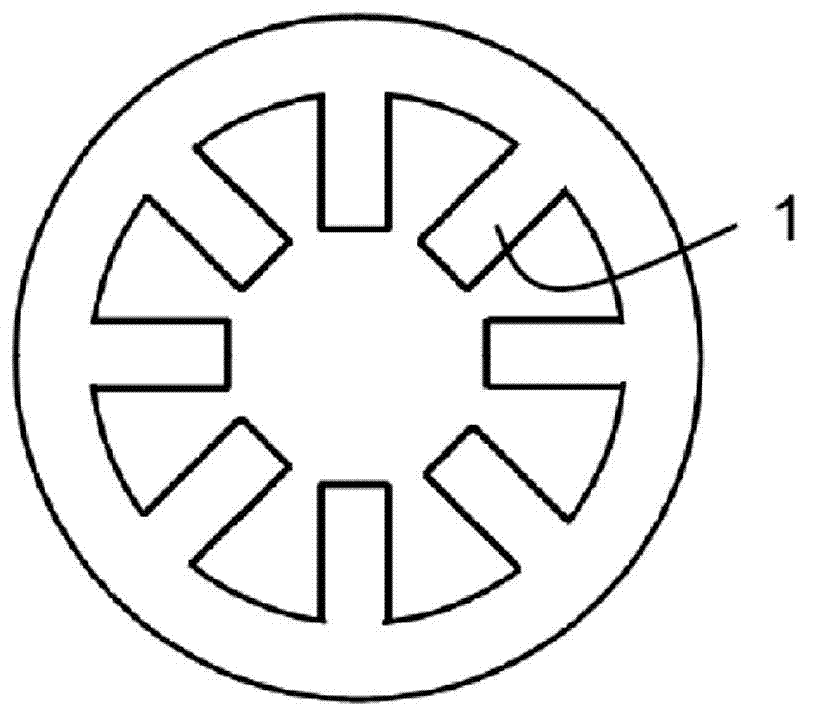

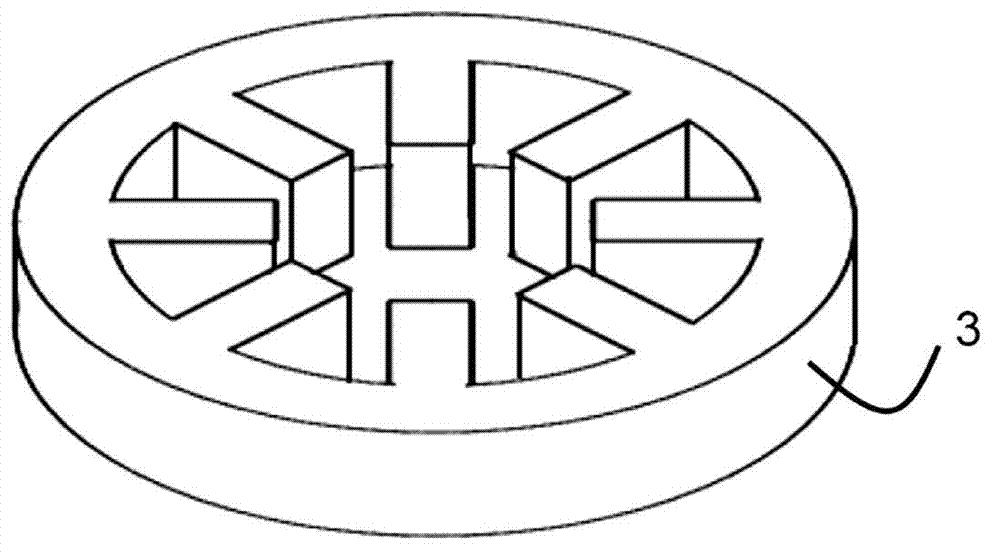

Amorphous, microcrystal or nanocrystalline alloy stator core and method for producing same

A nanocrystalline alloy and stator core technology, applied in the microcrystalline or nanocrystalline alloy stator core and its manufacturing, high-performance amorphous field, can solve the problems of large cutting thickness, low efficiency, and large axial height of the stator core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

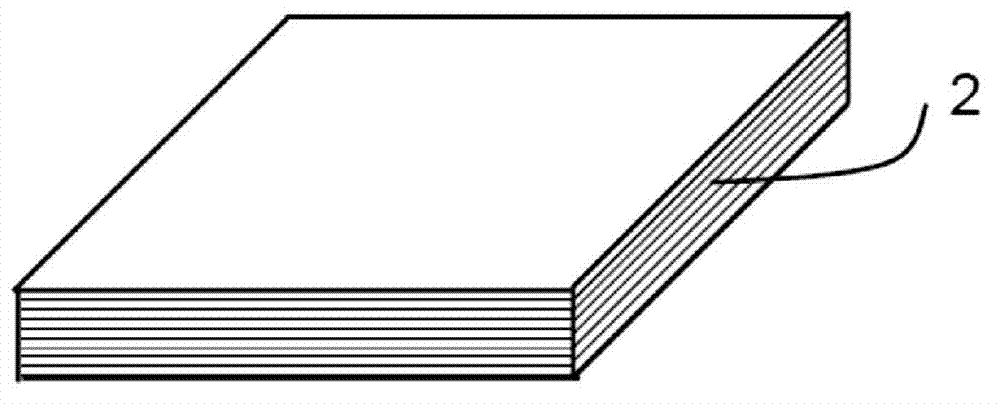

[0043] The composition of the strip for making the amorphous alloy stator core is Fe 80 Si 9 B 11 (at.%), the strip thickness is 30±1μm, the width is 142mm, and the surface is smooth and smooth. First, the amorphous strip was cut into square amorphous alloy flakes with a length of 142 mm using a cross-cutting device, and then these square amorphous alloy flakes were subjected to magnetic field annealing treatment under nitrogen protection. The described magnetic field annealing process conditions are as follows:

[0044] 1) Fill the electric furnace with nitrogen as a protective gas; 2) When the temperature rises to 250°C at a heating rate of 20°C / min, a DC magnetic field with a strength of 100mT is applied, and the direction of the magnetic field is perpendicular to the direction of the cast strip of the amorphous alloy strip. Hold at 250°C for 120min, and then heat up to 390°C at the same heating rate; 3) Keep the direction and intensity of the magnetic field unchanged, a...

Embodiment 2

[0053] The composition of the strip for making the amorphous alloy stator core is Fe 80 Si 9 B 11 (at.%), the strip thickness is 30±1μm, the width is 142mm, and the surface is smooth and smooth. First, the amorphous strip was cut into square amorphous alloy flakes with a length of 142 mm using a transverse shearing machine, and then these square amorphous alloy flakes were subjected to magnetic field annealing treatment under nitrogen protection. The magnetic field annealing treatment process is as follows:

[0054] 1) Fill the electric furnace with nitrogen as protective gas; 2) When the temperature rises to 280°C at a heating rate of 20°C / min, a DC magnetic field with a strength of 100mT is intensified, and the direction of the magnetic field is perpendicular to the direction of the cast strip of the amorphous alloy strip. Heat up to 390°C at the same heating rate; 3) Keep the direction and intensity of the magnetic field unchanged, and keep at 390°C for 120 minutes; 4) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com