Charging control guidance module for alternating-current charge spot of electric vehicle and guidance method of charging control guidance module

An AC charging pile, electric vehicle technology, applied in electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of long PWM waveform edge time, easy output overshoot burr, danger of electric shock to personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

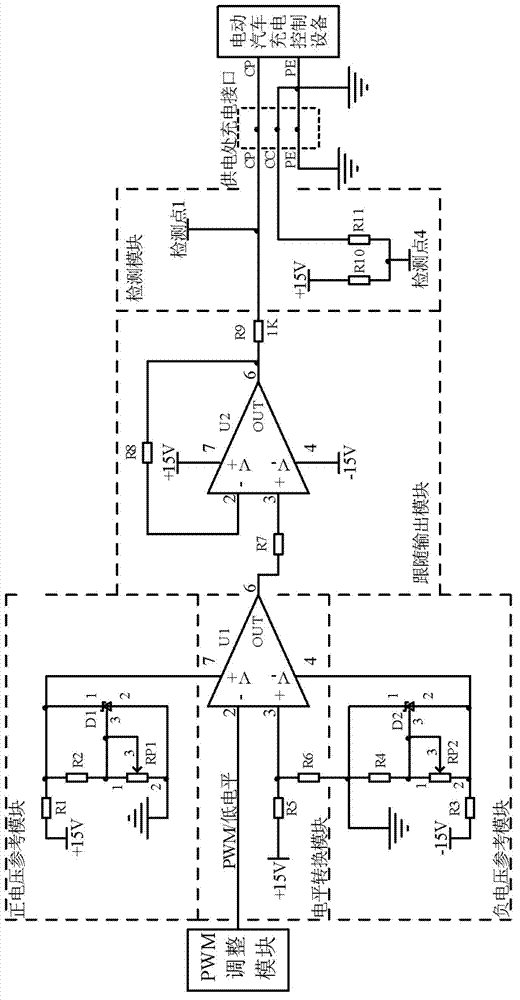

[0072] refer to figure 1 , the first embodiment of the charging control guide module for the electric vehicle AC charging pile of the present invention, which includes:

[0073] Positive voltage reference module 1, which is used to adjust a first power supply voltage to a preset value, and use it as the positive supply voltage of the operational amplifier U1 and adjust its output saturation positive voltage;

[0074] The negative voltage reference module 2 is used to adjust a second power supply voltage to a preset value, and use it as the negative supply voltage of the operational amplifier U1 and adjust its output saturation negative voltage;

[0075] A level conversion module 3, which is connected with the positive voltage reference module 1, the negative voltage reference module 2, the first power supply voltage and a PWM adjustment module 7, for receiving the digital pulse width modulation PWM signal output by the PWM adjustment module 7 and A reference voltage output by...

Embodiment 2

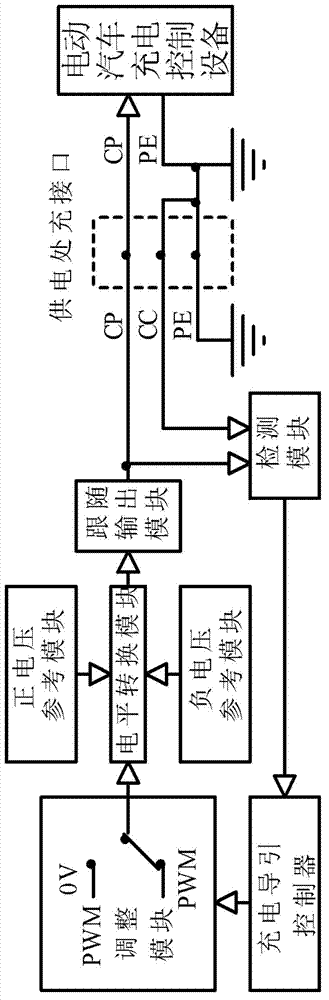

[0105] Charging control guide module for electric vehicle AC charging pile, which includes:

[0106] Positive voltage reference module 1, used to adjust a first power supply voltage to a preset value, and use it as the positive supply voltage of the operational amplifier and adjust its output saturation positive voltage;

[0107] Negative voltage reference module 2, used to adjust a second power supply voltage to a preset value, and use it as the negative supply voltage of the operational amplifier and adjust its output saturation negative voltage;

[0108] A level conversion module 3, which is connected with the positive voltage reference module, the negative voltage reference module, the first power supply voltage and a PWM adjustment module 7, for receiving the digital pulse width modulation PWM signal output by the PWM adjustment module 7 and A reference voltage output by a voltage dividing resistor connected to the first power supply voltage, and comparing the digital pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com