Coaxial nested type multi-mode ion source

A multi-mode, ion source technology, applied in the field of mass spectrometry ion source, can solve problems such as inability to meet rapid detection, inability to achieve simultaneous ionization of samples in multiple states, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

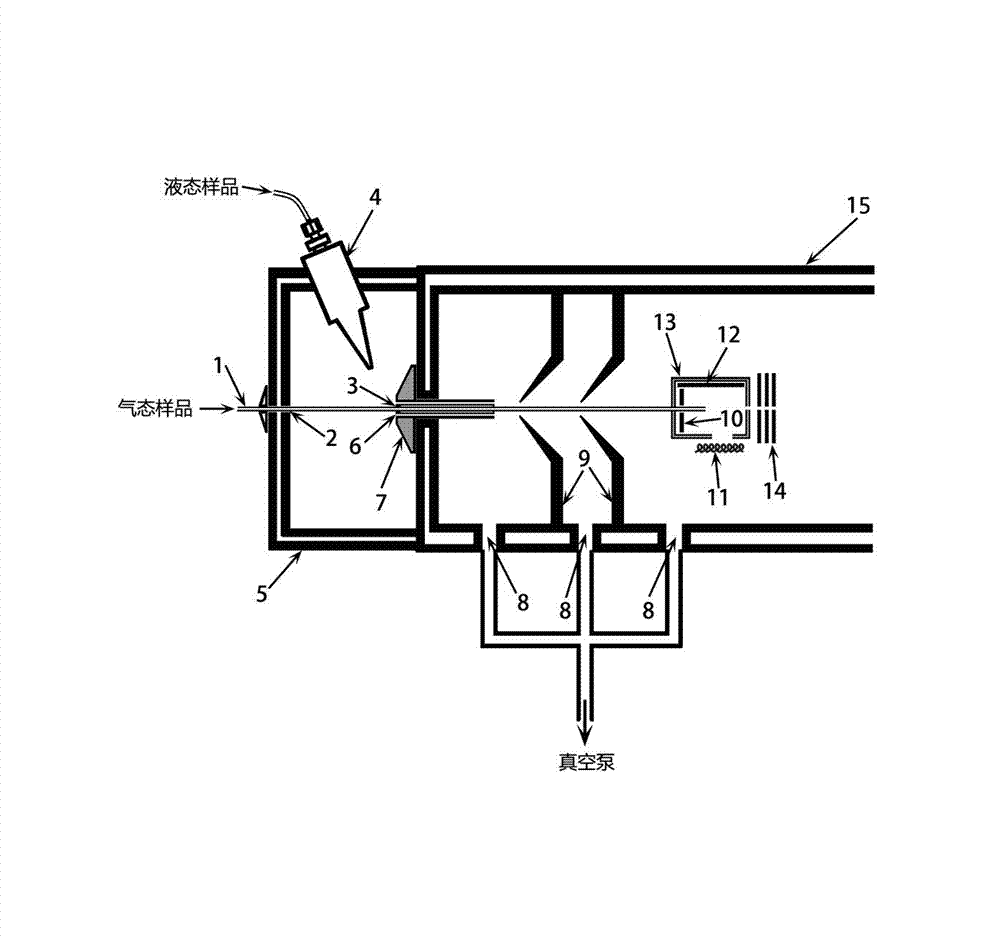

[0020] Example 1: Multi-mode ion source with coaxial nested structure

[0021] as attached figure 1 As shown, the present invention is a novel ion source device coaxially nested by an electron bombardment ion source and an electrospray ion source, wherein electron bombardment ionization-related accessories are located inside the mass spectrometry vacuum chamber (15), and the filament (11 ), an anode (12), a repeller (10), an electric lens group (14), a quartz capillary column (1) and a bombardment ionization chamber (13); the electrospray needle (4) is located in the spray chamber (5) , the spray chamber (5) is located directly in front of the front end of the mass spectrometer vacuum chamber (15); another small opening (2) is opened at the position opposite to the entrance of the spray chamber (5) to the quartz capillary column (1), so that the quartz capillary column ( 1) It can enter the spray chamber (5); the stainless steel capillary conduit (6) is located in front of th...

Embodiment 2

[0022] Example 2: Electron bombardment ionization working mode

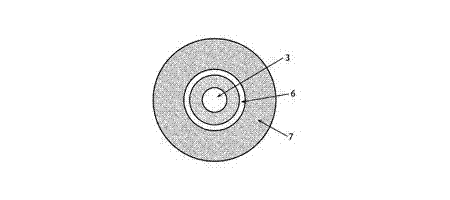

[0023] like figure 1 As shown, the gaseous compound to be tested enters the quartz capillary column (1) with the helium flow, and passes through the opening (2) of the spray chamber (5) and the capillary inlet located at the center of the injection cone (7) in the mass spectrometry vacuum chamber (15) (3) ( figure 2 ) and two parallel sampling cones (9) reach the bombardment ionization chamber (13); the vacuum degree of the bombardment ionization chamber (13) reaches 10 -4 below pa, the voltage applied to the filament (11) at this time emits an electron beam with an energy of 70 eV, which collides with the sample molecules in the vertical direction and breaks them into charged fragments of different masses; charged fragment ions Under the action of the repeller (10), it is pushed into the electric lens group (14), modulated by the electric lens group (14) to form an electron bombardment ion beam current and i...

Embodiment 3

[0025] Example 3: Electrospray ionization mode

[0026] like figure 1 As shown, after the liquid sample is injected into the electrospray nozzle (4), a high-voltage direct current is applied to the electrospray nozzle (4) to ionize the outflowing droplets, and the charged droplets are rapidly atomized and removed in the spray chamber (5). Solvation, and then the charged ions are input into the mass spectrometry vacuum chamber (15) through the stainless steel capillary tube (6) passing through the capillary inlet (3); after the electrospray ions are desolvated by two parallel sampling cones (9), It passes through the area where the electron bombardment source is located and enters the subsequent modulation device, which is modulated to form an electrospray ion beam, and finally input into the mass analyzer for mass analysis.

[0027] At this time, the electron bombardment ion source stops working and is in a standby state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com