Comprehensive protection device automatic test system

A technology of automatic test system and comprehensive protection device, which is applied in error detection/correction, instrumentation, electrical digital data processing, etc., can solve problems such as low efficiency, many unreliable factors, and high risk, so as to improve efficiency and reduce production testing The effect of cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

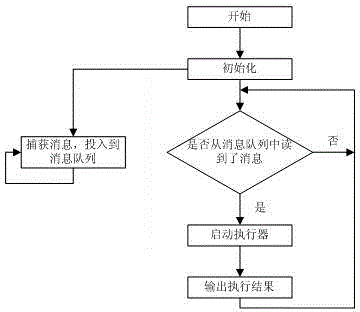

Method used

Image

Examples

Embodiment Construction

[0090] 1.1 Functional requirements of the present invention:

[0091] Communication function detection: The PC sends a communication command to check whether the device under test responds correctly. If there is no reply or a wrong reply then there is a problem with the communication channel.

[0092] Single-chip ROM self-test: Check whether there is a bad bank in the ROM of the single-chip microcomputer. Use the sampling address read and write detection scheme. After the device receives the ROM self-test command issued by the PC, the device selects fixed addresses in several fixed areas to perform read and write operations. If there is an inconsistency between the written and read data. It means that there is a bad bank in the ROM area. Then it is determined that there is a problem with the ROM of the single-chip microcomputer.

[0093] Single-chip RAM self-test: Check whether the single-chip RAM has a bad bank. Use the sampling address read and write detection scheme. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com