Central control system of automotive practical training platform

A technology of a central control system and a training platform, which is applied in the field of automobile teaching systems, can solve problems such as the inability to realize systematic teaching, single training functions, and increase teaching costs, so as to meet the needs of actual testing and hands-on ability, improve teaching quality, The effect of saving teaching costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further introduced below by accompanying drawing:

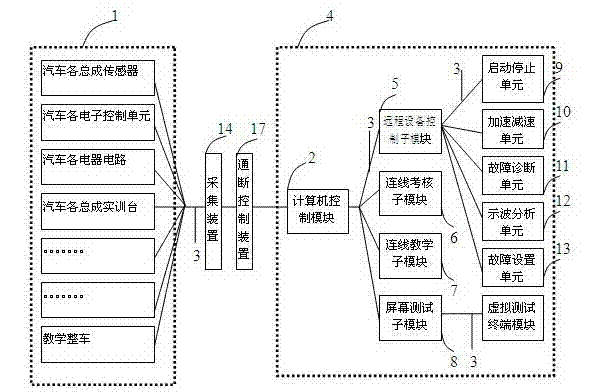

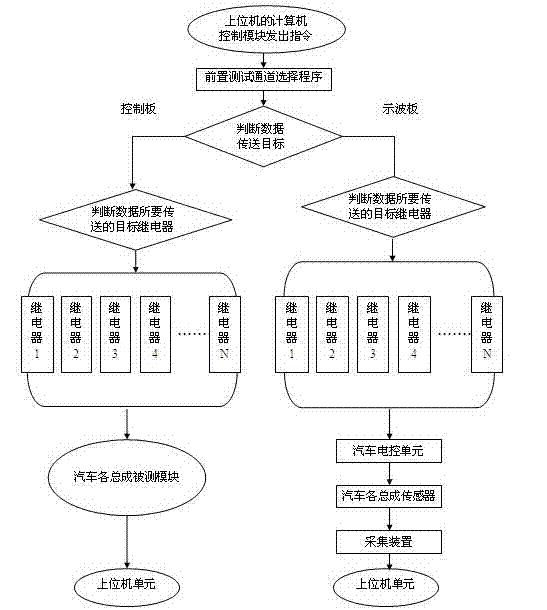

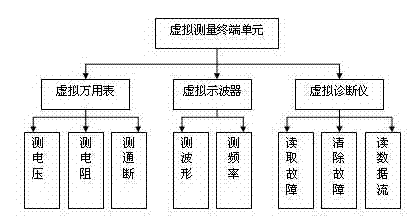

[0045] The connection structure of the present invention is shown as Figure 1 : It is formed by combining the tested module (1), computer control module (2), electrical connector (3), acquisition device (14), on-off control device (17) and upper computer (4) of each automobile assembly A system that operates through the interaction of software and physical car assembly components. The upper computer (4) is connected with the acquisition device (14), the on-off control device (17) and the tested modules (1) of the automobile assembly through the electrical connector (3), Real-time interactive execution of communication, control and measurement tasks. The present invention can test different automobile equipments according to the user's choice. The measured modules (1) of each automobile assembly described in the present invention are each automobile assembly sensor, each automobile electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com