Testing device of machine tool guide rail protective cover

The technology of a test device and protective cover is applied in the field of test device of machine tool guide rail protective cover, which can solve the problems of non-parallel and interference, and achieve the effects of simple production, saving verification time and reliable experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

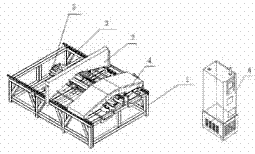

[0013] A test device for machine tool guideway protective cover, such as figure 1 As shown: it includes a base bracket 1, on which a motor 5 controlled by a controller 6 is fixed, and a guide rail 3 is connected to the motor 5, and the guide rail 3 cooperates with the fixed frame 2 at the lower part through a bearing, and the upper part of the guide rail 3 is covered with A mobile truss 4 cooperating with the above-mentioned fixed frame 2.

[0014] The bearing is a linear bearing.

[0015] During the test, the mobile truss 4 is connected with the guide rail protective cover to be tested, and the working principle of the machine tool machining center is simulated, so that it can be tested together with the mobile truss in high-speed motion, and the controller 6 is set through the parameters, and the controller 6 sends its signal Accurately transmit to the motor 5 driver to accurately control the motion state of the test bench, and install the designed and produced new machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com