Drying apparatus

A drying device and cavity technology, applied in washing devices, drying chambers/containers, local stirring dryers, etc., can solve the problems of high noise, long time, uneven drying, etc., and achieve uniform temperature distribution, uniform drying, The best drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

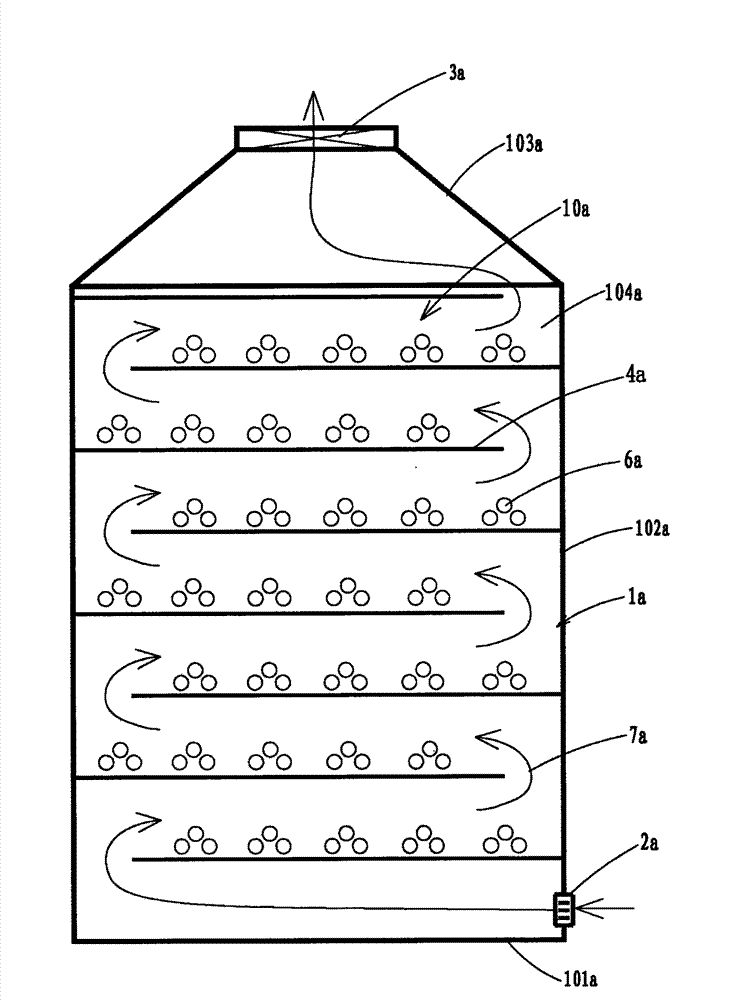

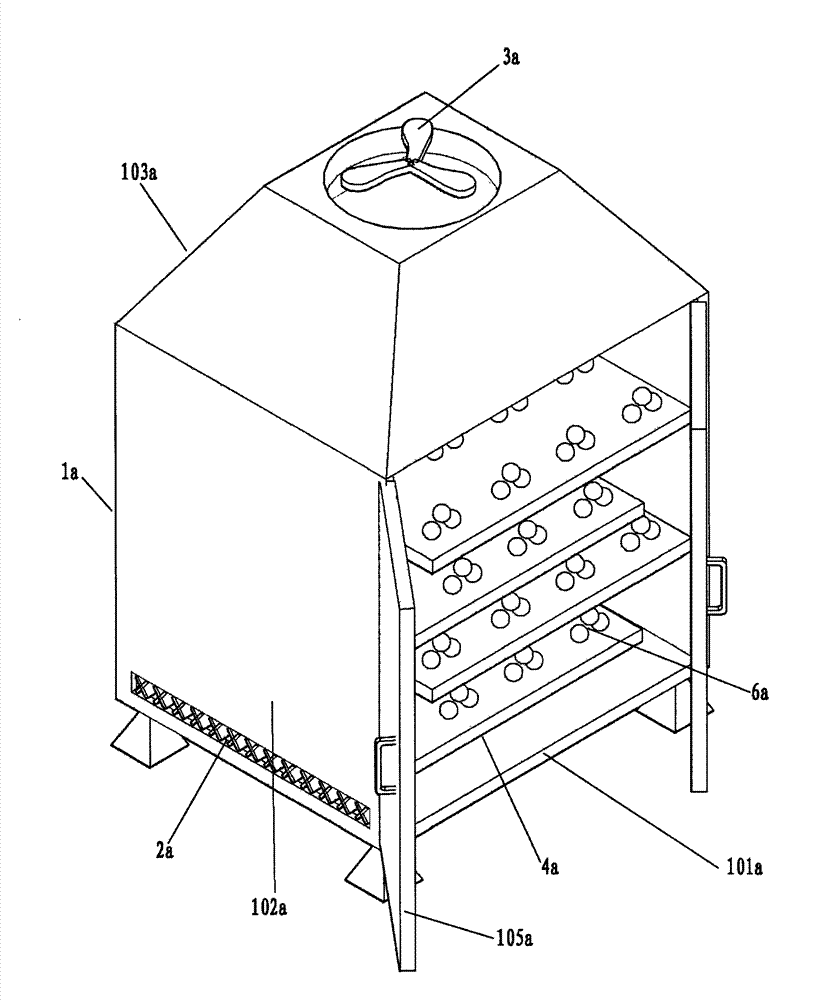

[0033] see figure 1 , figure 2, the present invention provides a kind of drying device embodiment, it comprises shell 1a, and this shell 1a is surrounded by base plate 101a, left and right side plates 102a, rear plate 104a, switchable front door plate 105a and platform-shaped upper plate 103a The cross section of the lower part is quadrilateral, polygonal or circular, and the upper part is a tower-shaped hollow cavity of a platform; a plurality of horizontal partitions 4a are arranged at intervals in the cavity, so that a space unit 10a is formed between each horizontal partition 4a, Items 6a to be dried can be placed on each horizontal partition 4a. Specifically, the setting of each horizontal partition 4a can be equidistant, and can also be set as non-equidistant according to different needs, and the setting of the horizontal partition 4a in the cavity can be fixed or movable, The spacing between each horizontal dividing plate 4a can be adjusted at any time as required (t...

Embodiment 2

[0047] see image 3 , Figure 5 , the present invention provides another embodiment of the drying device, which includes a housing 1b, and the housing 1b is surrounded by a bottom plate 101b, left and right side plates 102b, a top plate 103b, a rear plate 104b, and a switchable front door plate 105b to form a cabinet shaped cavity. In the cavity, a plurality of vertical partitions 4b are arranged at intervals, so that a space unit 10b is formed between each vertical partition 4b, and the items to be dried 6b are placed in each space unit 10b. Specifically, the arrangement of the vertical partitions 4b can be equidistant or non-equidistant according to different needs, and the arrangement of the vertical partitions 4b in the cavity can be fixed or movable. , the distance between the vertical partitions 4b can be adjusted at any time as required. Between the upper end or lower end of each of the vertical partitions 4b and the top plate 103b and the bottom plate 101b of the ca...

Embodiment 3

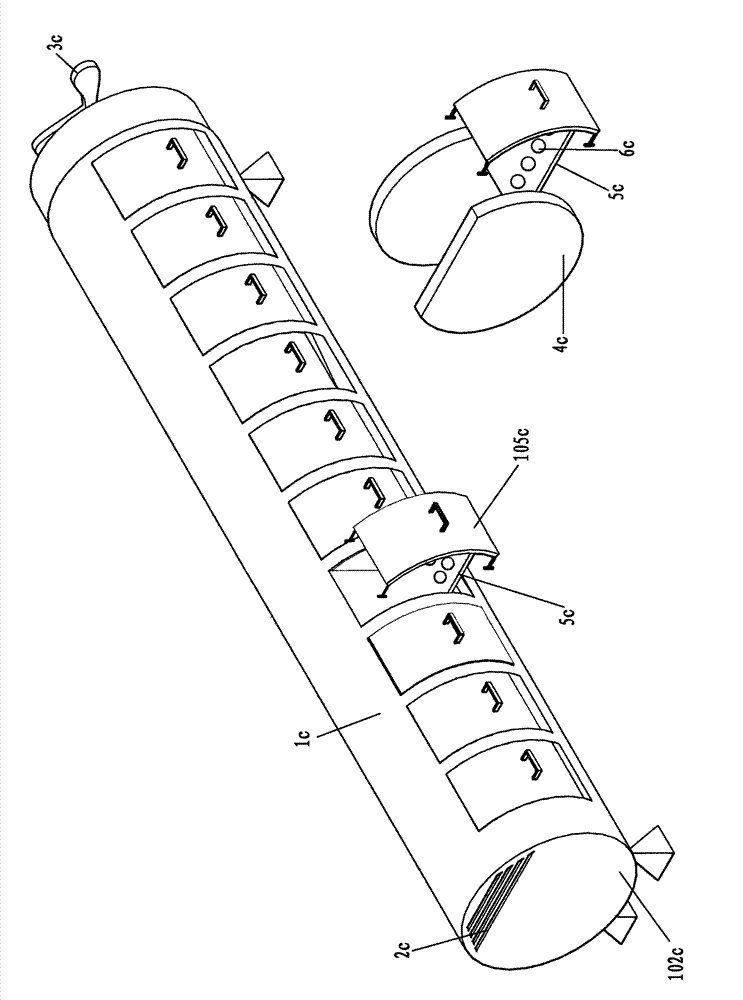

[0055] see Figure 6-Figure 9 , the present invention provides a third embodiment of a drying device, which includes a housing 1c, which is a horizontally arranged cylindrical cavity with a circular, oval or polygonal section ( Figure 6-Figure 9 Shown is a cylindrical cavity with a circular cross-section), the partitions 4c are perpendicular to the axis of the cylindrical cavity and are arranged at intervals, so that a plurality of space units 10c arranged horizontally are formed between the partitions 4c, Items 6c to be dried are placed in each space unit 10c. Specifically, the arrangement of the partitions 4c can be equidistant or non-equidistant according to different needs, and the arrangement of the partitions 4c in the cavity 1c can be fixed or movable, The distance between the vertical partitions 4c can be adjusted at any time as required. There are cavities (or spacing) between the upper end or the lower end of each of the partitions 4c and the upper or lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com