Downhole blow-out preventer with automatic controlling and anchoring function

A blowout preventer and anchoring technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of difficult acquisition and transmission of electrical signals, and difficulty in popularization, so as to achieve simple structure and prevent blowout , The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

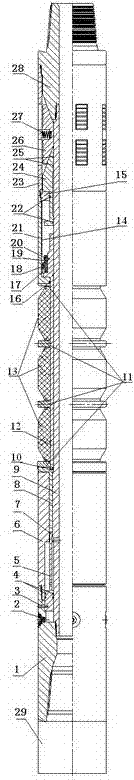

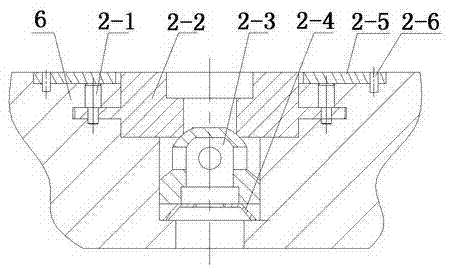

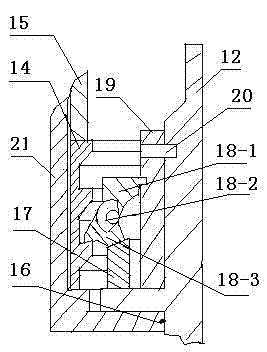

[0013] The downhole blowout preventer consists of a safety valve 29 in the drill string and a blowout preventer seat seal anchoring device, such as figure 1 shown. The safety valve 29 in the drill string will be selected according to the depth of the well, and it will be installed at the end of the downhole blowout preventer near the drill bit. Its function is to close the annular space in the drill string by relying on this safety valve in case of a well kick, so as to avoid mud upwelling in the drill string. . In the blowout preventer seat seal anchoring device, the lower joint 1 and the upper joint 28 ensure the correct connection and fixation of the parts in the blowout preventer; the outer wall check valve assembly 2 installed on the outer cylinder 6 is composed of the fixing pin 2-1, Gland 2-2, pressure cap 2-3, butterfly spring 2-4, baffle plate 2-5 and locking pin 2-6, when the pressure in the outer annular space of the downhole blowout preventer is greater than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com