Positive pressure and negative pressure combined grouting method

A technology of positive and negative pressure and grouting, which is applied in construction, infrastructure engineering, etc., can solve problems such as increasing grouting pressure, clogging, and reducing the speed of grout flow, so as to avoid grout clogging, save grout volume, and have significant technical advantages and the effect on economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

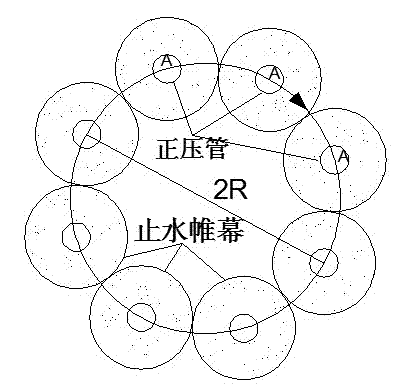

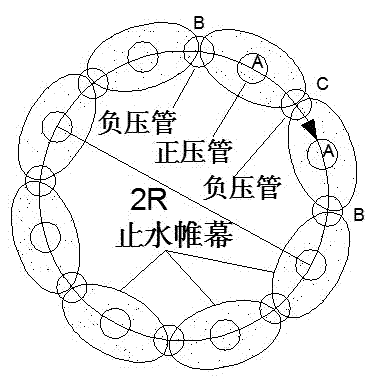

[0011] Embodiment 1: The method is as follows: first, arrange three grouting flower pipes in the pre-water stop area, two of the three grouting flower pipes are negative pressure grouting pipes, one is positive pressure grouting pipes, and two of them are positive pressure grouting pipes The negative pressure grouting pipes are B pipes and C pipes, and the B pipes and C pipes are connected to the vacuum pump. One positive pressure grouting pipe is A pipe, and the A pipe is connected to the slurry storage tank. After applying positive pressure to the slurry storage tank, At the same time, a negative pressure of 1 standard atmospheric pressure is applied to pipe B and pipe C to form a continuous crack channel between tube A and tube B and between tube A and tube C. The crack channel begins with tube A and ends with tube B and tube C respectively. In tube C, the slurry spreads along the AB and AC elliptical channels under the action of the pressure gradient; when the slurry reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com