Efficient metal paint remover and preparation method thereof

A technology of paint remover and preparation method, which is applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems such as the limitation of applicable surface, and achieve the effect of small solvent volatilization, excellent corrosion inhibition effect and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

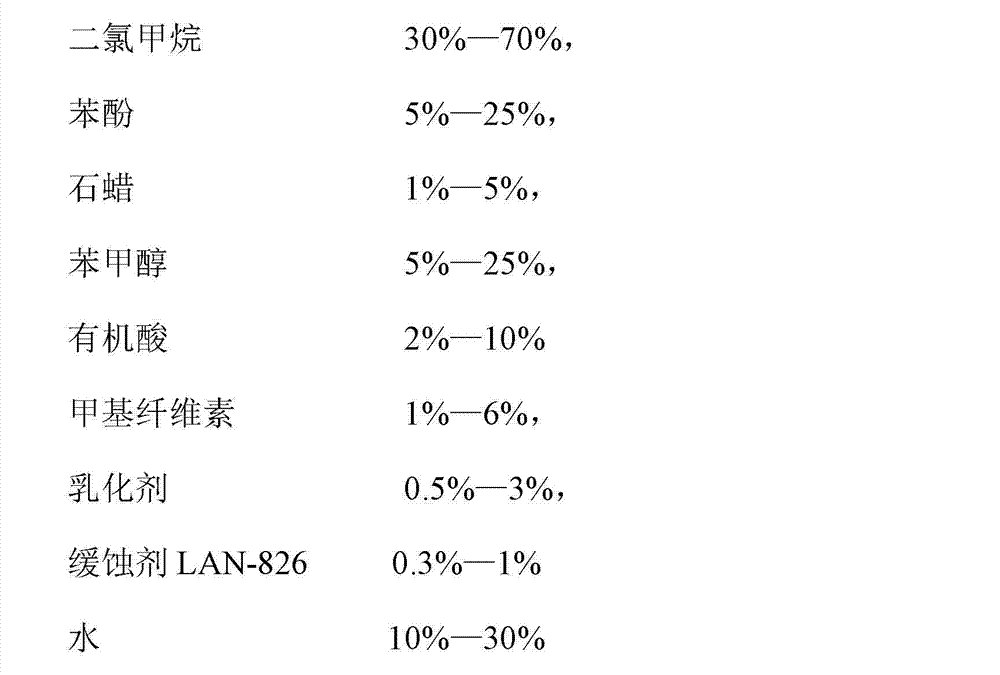

Method used

Image

Examples

Embodiment 1

[0017] Weigh 50kg of dichloromethane, 15kg of phenol, 2kg of paraffin, 5kg of benzyl alcohol, 8kg of formic acid, 1kg of methylcellulose, emulsifier (Tween-80 0.65kg, Span-80 1.35kg), corrosion inhibitor LAN-826 0.008kg, water 17kg.

[0018] Preparation method:

[0019] (1) Add paraffin, water, emulsifier, and methylcellulose into the reaction kettle, and stir and emulsify at 60°C for 0.5 hours;

[0020] (2) Then add benzyl alcohol, formic acid and corrosion inhibitor, maintain the temperature at 50°C, and stir for 0.5 hours;

[0021] (3) Finally, add the mixture of dichloromethane and phenol, maintain the temperature at 40°C, stir for 0.8 hours, and mix well;

[0022] (4) Cool to room temperature to obtain a paste-like high-efficiency metal paint remover.

[0023] Effect test: The prepared high-efficiency metal paint remover is uniformly coated on the Boeing aircraft paint layer model (aluminum alloy substrate) into a block of 100mm×200mm, with a thickness of about 0.25mm;...

Embodiment 2

[0025] Weigh 55kg of dichloromethane, 10kg of phenol, 3kg of paraffin, 8kg of benzyl alcohol, 9kg of acetic acid, 2kg of methylcellulose, emulsifier (Tween-80 0.95kg, Span-80 2.05kg), corrosion inhibitor LAN-826 0.006kg, water 10kg.

[0026] Preparation method:

[0027] (1) Add paraffin, water, emulsifier, and methylcellulose into the reaction kettle, and stir and emulsify at 70°C for 0.4 hours;

[0028] (2) Then add benzyl alcohol, acetic acid and corrosion inhibitor, maintain the temperature at 70°C, and stir for 0.3 hours;

[0029] (3) Finally, add the mixture of dichloromethane and phenol, maintain the temperature at 40°C, stir for 0.5 hours, and mix well;

[0030] (4) Cool to room temperature to obtain a paste-like high-efficiency metal paint remover.

[0031] Effect test: The configured high-efficiency metal paint remover is evenly coated on the paint layer of a certain type of Volkswagen car door (carbon steel substrate) into a block of 100mm×200mm, with a thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com