Production equipment for coating and gold-stamping amboss of wallpaper

A technology of fabric bronzing embossing and production equipment, which is applied in paper, papermaking, gold powder printing and other directions, can solve the problem of not being able to complete coating, bronzing and embossing at the same time, and achieve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

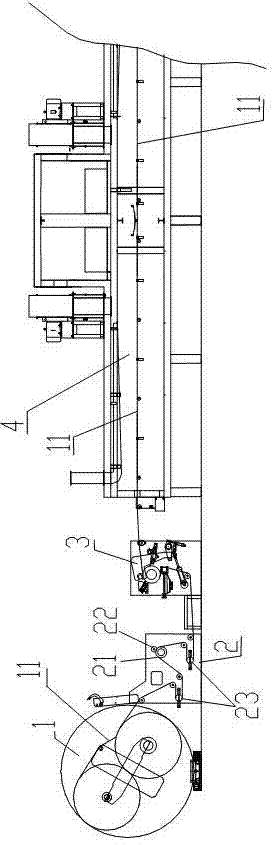

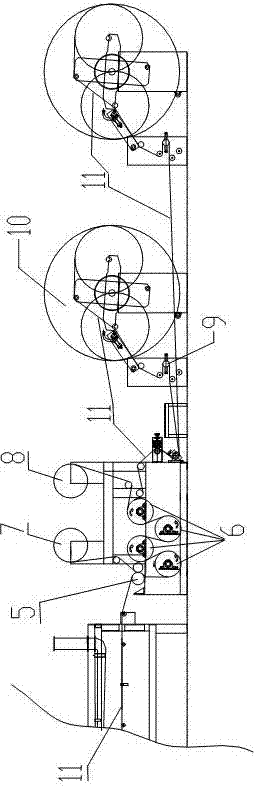

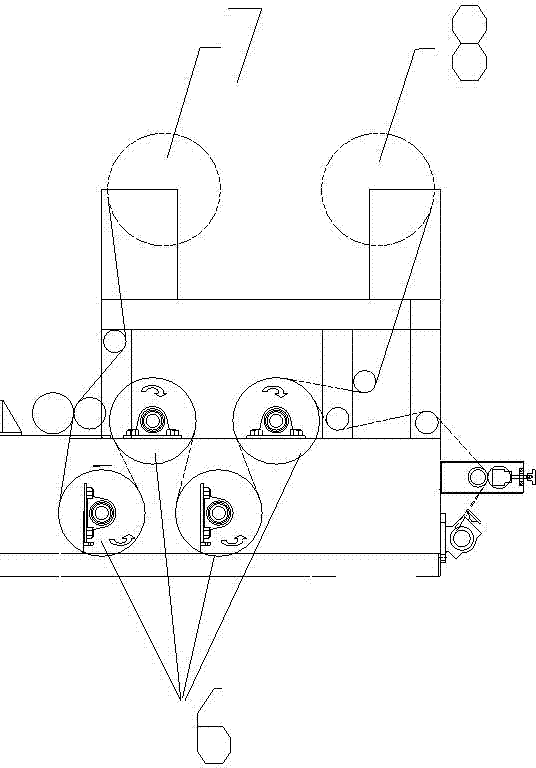

[0023] see figure 1 and figure 2 The structure of the wallpaper coating bronzing and embossing production equipment provided by the present invention mainly includes a discharging unit 1, a discharging traction unit 2, a coating unit 3, an oven unit 4, an embossing bronzing unit 5, a cooling unit 6 and a receiving unit 10. The wallpaper raw material 11 to be processed passes through the discharging unit 1, the discharging traction unit 2, the coating unit 3, the oven unit 4, the embossing bronzing unit 5, the cooling unit 6, and finally enters the receiving unit 10. The device also includes a control system for controlling each of the above-mentioned structural units, and the control system includes control sensors arranged on each of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com