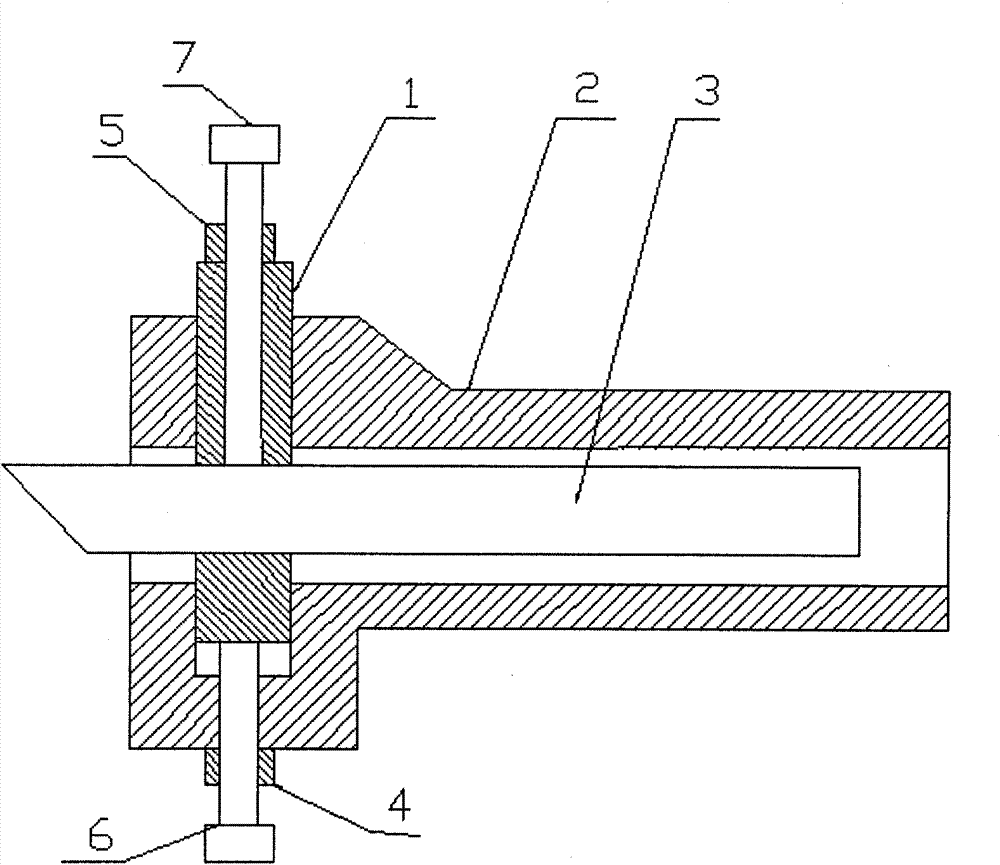

Structure of novel threading tool

A thread turning tool, a new type of technology, is applied in the accessories of toolholders, tools for lathes, turning equipment, etc., which can solve the problems of less repeated sharpening times and waste of tool head materials, and achieve the goal of overcoming the low number of repeated sharpening times. , Easy installation and adjustment, short manufacturing and adjustment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Make a hollow c along the full length direction of the shank of the knife bar (2), make a blind hole d at the head of the knife bar (2), make a threaded through hole at the bottom of the blind hole, and make a threaded through hole at the bottom of the knife bar (2). The through-hole c in the direction of the entire length of the shank is perpendicular to the axis of the blind hole d in the head of the tool bar, and the slider (1) is installed in the blind hole d in the head of the tool bar (2). Open a through hole on the waist, install the slider (1) in the blind hole d of the head of the knife rod, and make the through hole opened on the waist align with the through hole c in the entire length direction of the handle of the knife rod, and thread The long cutter head (3) starts from the tail, installs it in the opening c between the waist hole of the slider and the full length direction of the cutter bar, exposes the length of the cutter tip, adjusts the slider (1) with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com