Intelligent motor power saver

A technology for intelligent motors and power savers, which is applied in motor generators/starters, starters of single multi-phase induction motors, AC motor control, etc., and can solve the problem of power terminal utilization rate of only 30% to 40%, low work efficiency, Low load rate and other problems, achieve significant power saving effect, convenient debugging and installation, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

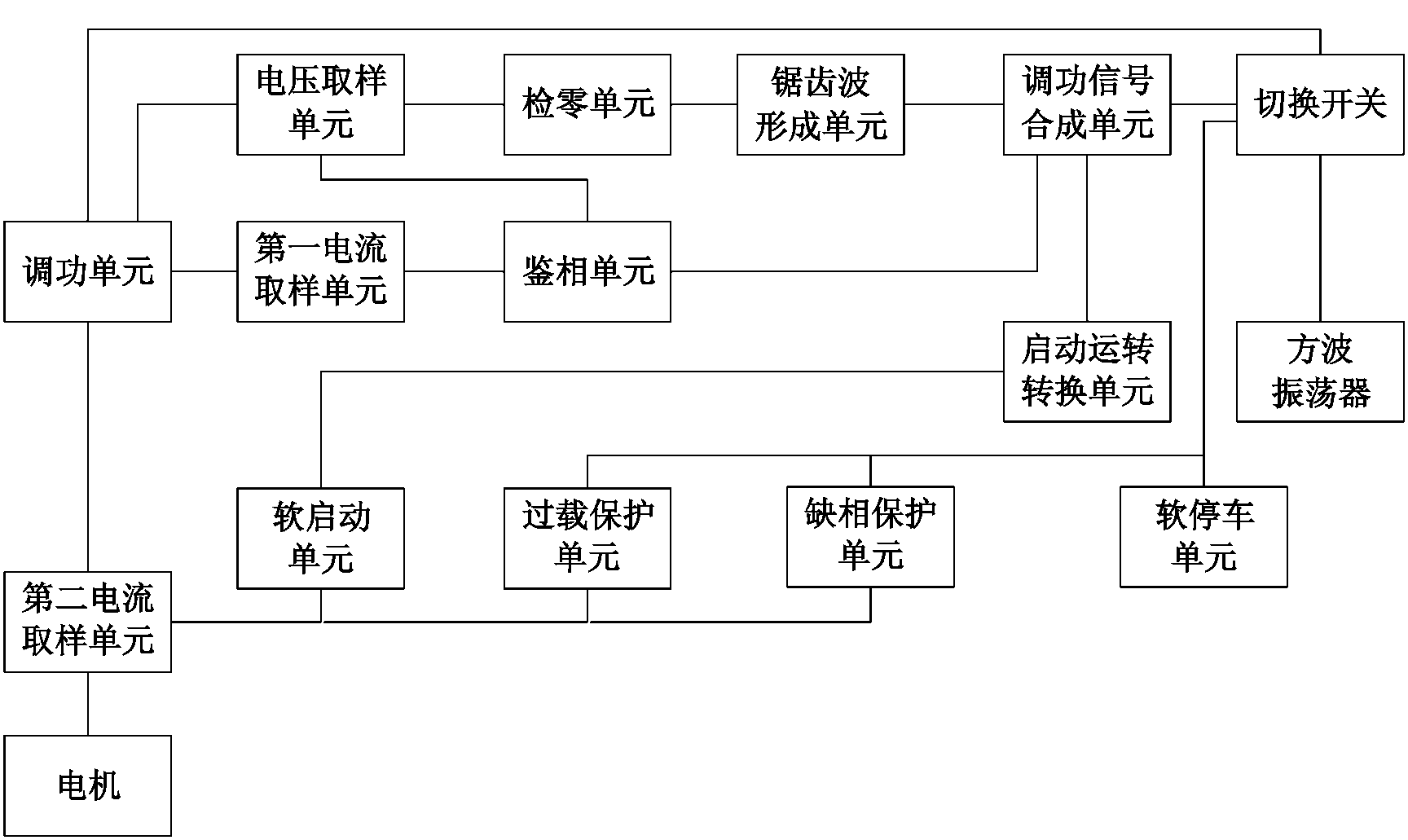

[0015] figure 1 It is a structural schematic diagram of an intelligent motor power saver in a specific embodiment of the present invention. Such as figure 1 As shown, the intelligent motor saver includes a power adjustment unit, a voltage sampling unit, a zero detection unit, a sawtooth wave forming unit, a power adjustment signal synthesis unit, a square wave oscillator, a phase detection unit, a first current sampling unit, a switch, A second current sampling unit, a soft start unit, an overload protection unit, a phase loss protection unit, a soft stop unit and a start-up operation conversion unit.

[0016] The second current sampling unit is connected to the motor, the second current sampling unit is also connected to the power adjustment unit, the power adjustment unit is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com