Display device

A technology for display devices and shutter plates, which can be applied to microstructure devices, manufacturing microstructure devices, and microelectronic microstructure devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

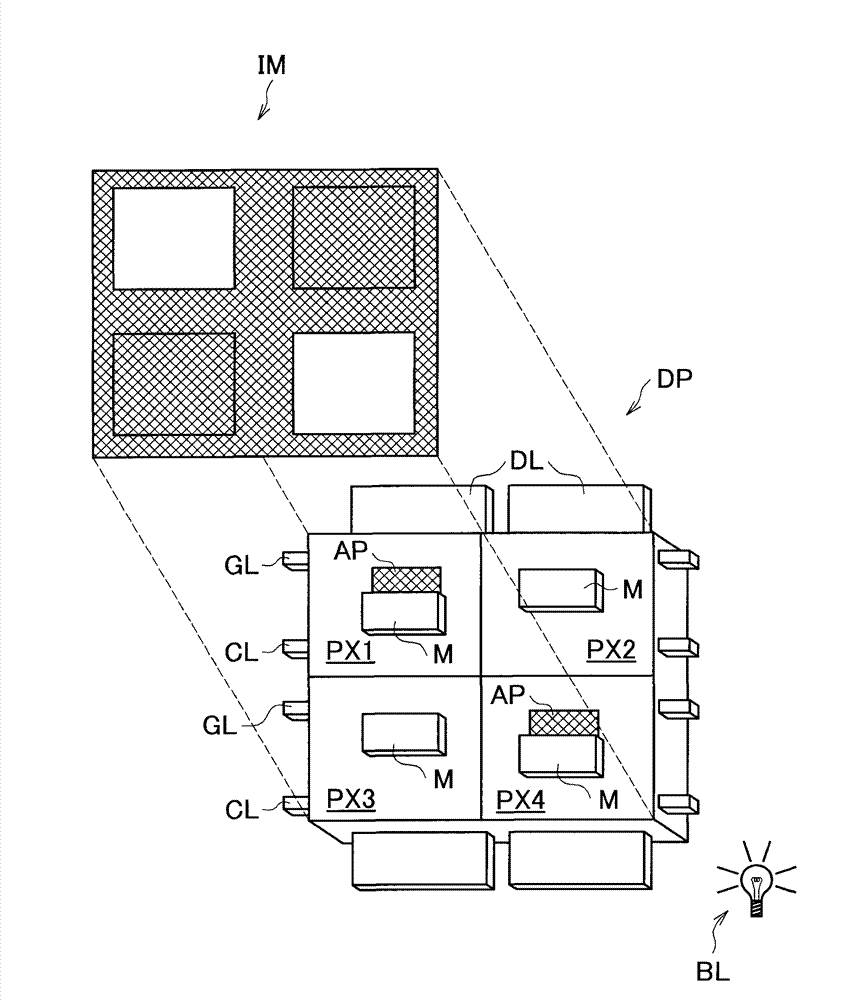

[0046] figure 1 It is a schematic diagram of the display device DP according to the first embodiment of the present invention. The display device DP has a shutter assembly M as a light modulator on each of a plurality of pixels arranged in a matrix. exist figure 1 In the schematic diagram of , the pixels PX1 and PX4 are in the open state and can transmit the light from the backlight BL of the hole AP to display white on the image IM. In addition, the pixels PX2 and PX3 are closed and block the transmission of light from the backlight BL, and display black on the image IM.

[0047]In addition, the display device DP includes a first substrate having a switching element on each of the plurality of pixels, and a second substrate disposed opposite to the first substrate. The shutter assembly M is disposed between the first substrate and the second substrate.

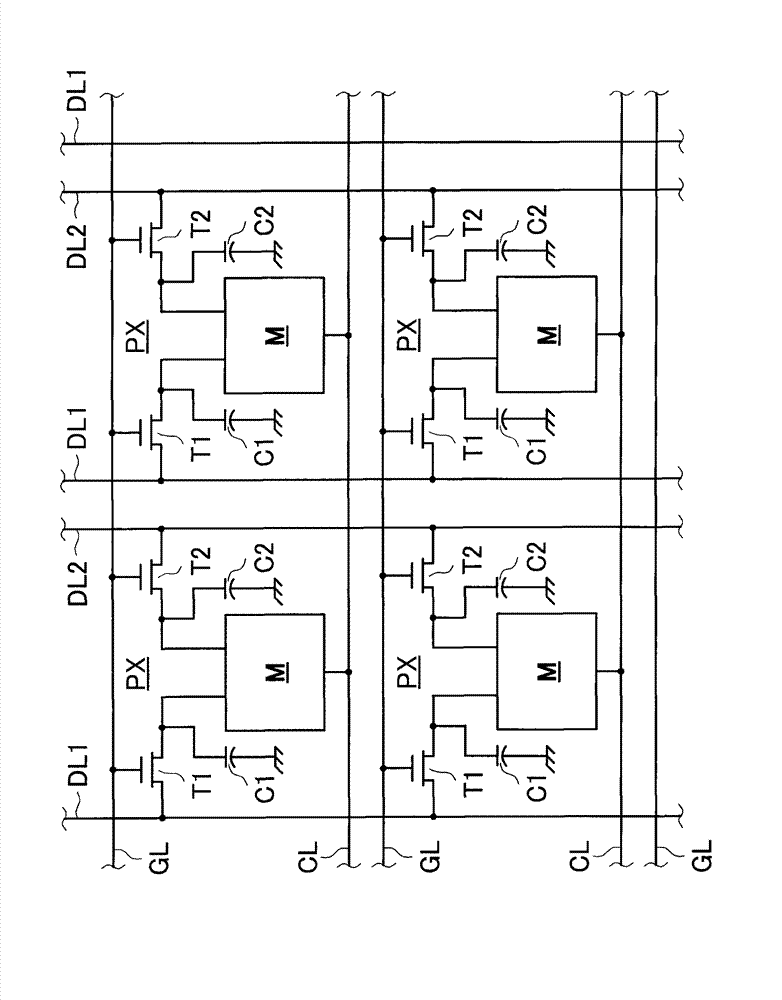

[0048] figure 2 It is a figure which shows the equivalent circuit of the 1st board|substrate in this embodiment. A...

no. 2 Embodiment approach

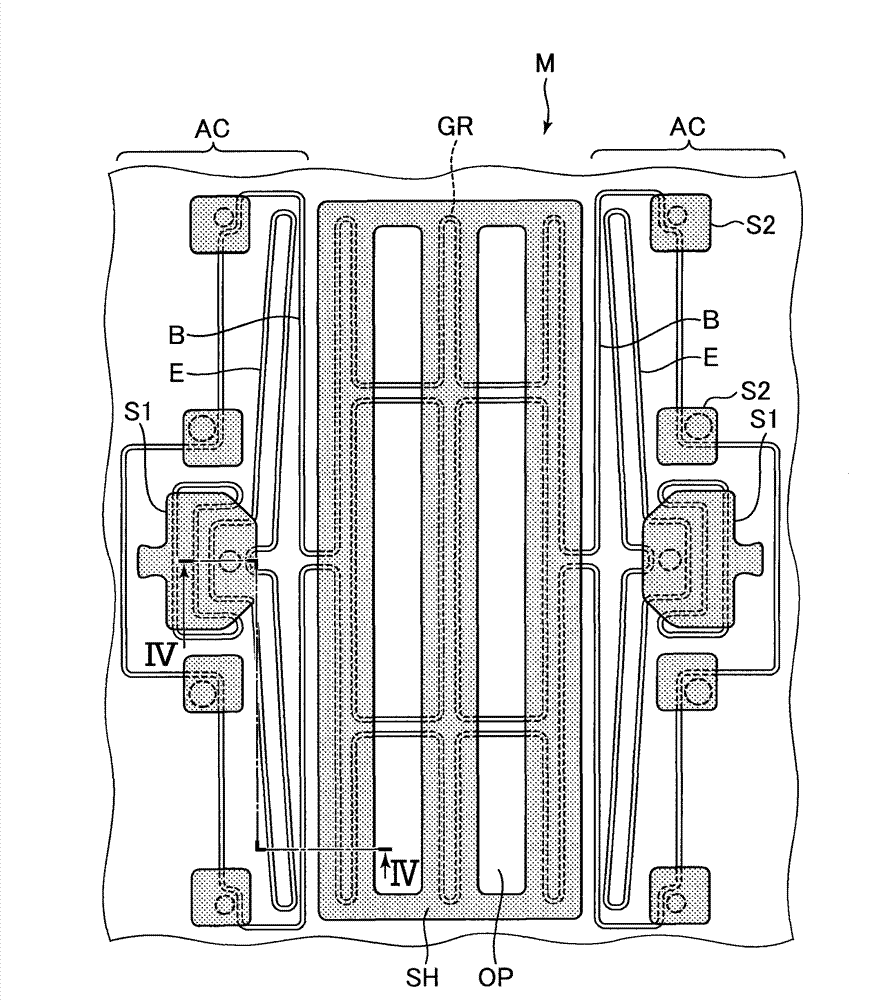

[0076] Next, a second embodiment of the present invention will be described. Image 6 is a diagram showing the cross section of the drive electrode E, the beam portion B, and the shutter SH in the second embodiment, and shows Figure 3A The portion from the drive electrode E to the shutter SH in the IV-IV section. The second embodiment differs from the first embodiment except that the region outside the drive electrode E, that is, the region inside the beam portion B is fully exposed through the half-tone mask in the first photolithography process. The situation is roughly the same.

[0077] Figure 7A ~ Figure 7C It is a figure explaining the state of manufacturing the shutter assembly M in 2nd Embodiment. First, if Figure 7A As shown, on the resist film RS1 used as a sacrificial layer, the portion where the drive electrode E and the beam portion B are formed is processed by full exposure in the same manner as the portion of the concave portion Sc described in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com