Infrared cut-off filter with blue glass

A technology of infrared cut-off and blue glass, which is applied in the field of optical filters, can solve the problems of reducing image quality, weakening the cut-off effect, and affecting image quality, and achieves the effects of uniform and clear color, overcoming color deviation, and reducing white fog phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

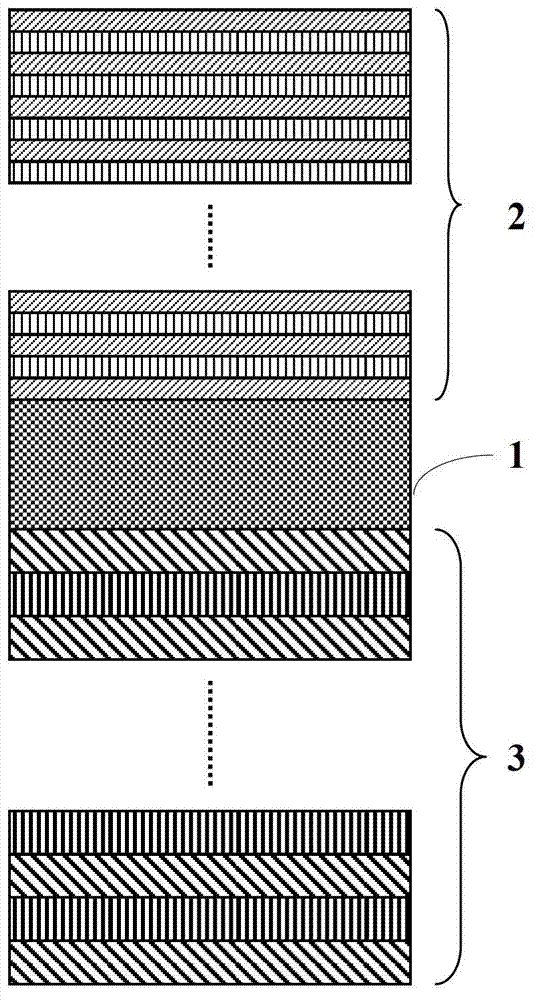

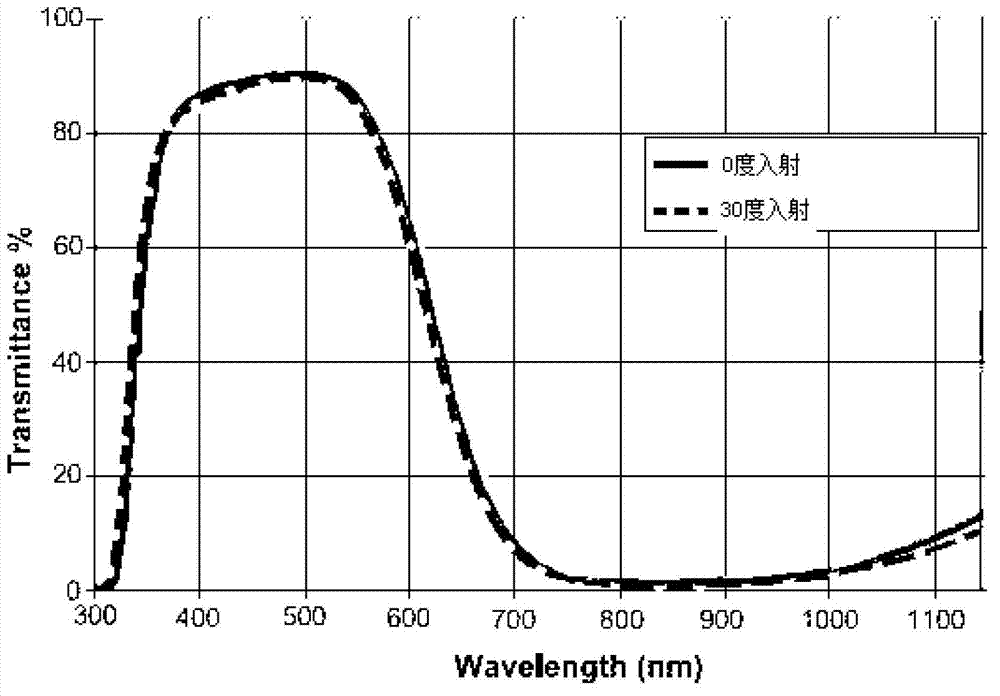

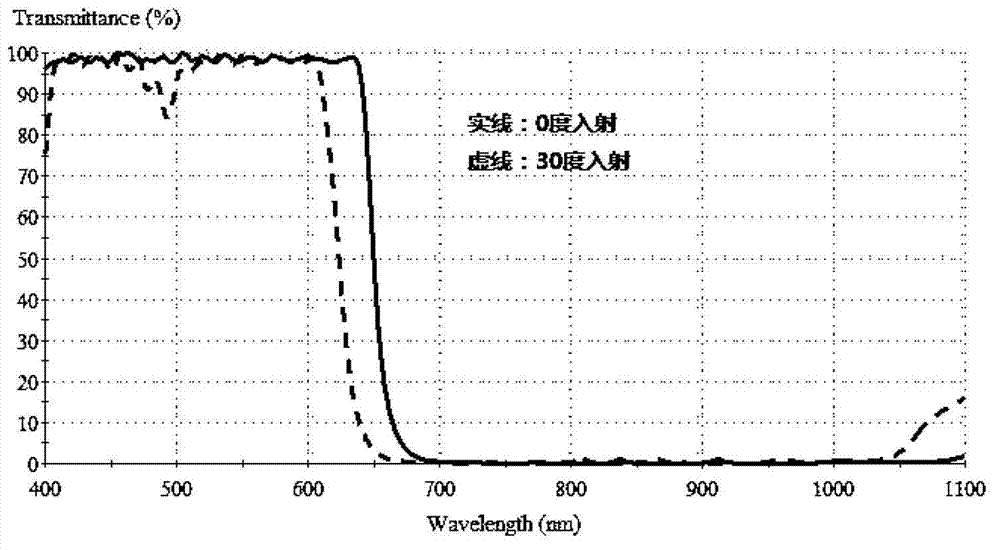

[0024] The composite thin-film blue glass infrared cut-off filter of the present invention comprises a substrate, an infrared short-wave cut-off film stack 2 is arranged on the front surface of the substrate, and an infrared long-wave cut-off film stack 3 is arranged on the rear surface of the substrate, wherein the substrate material is blue glass, and the thickness is between Between 0.1mm-0.55mm, the commonly used specifications are 0.1mm, 0.145mm, 0.21mm, 0.3mm, 0.45mm and 0.55mm. The infrared short-wave cut-off film stack and the infrared long-wave cut-off film stack 3 are respectively stacked alternately by thin films of high and low refractive index materials, wherein the high refractive index material is TiO 2 、 Ta 2 o 5 , Nb 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com