High-speed waterspout inertia-ejection cylinder

A projectile cylinder and water column technology, which is applied to liquid spray guns, weapons without explosives, offensive equipment, etc., can solve the problems of damage to the spray shape of the water column in the projectile cylinder and inability to spray, and achieve the effect of easy reuse and prevention of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

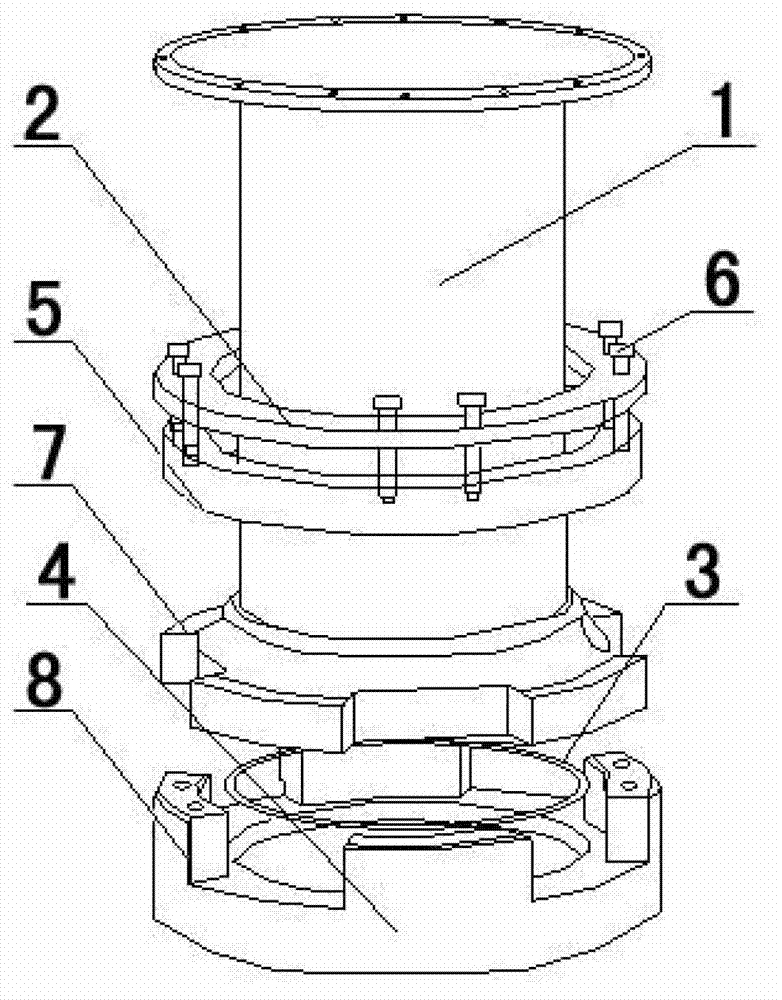

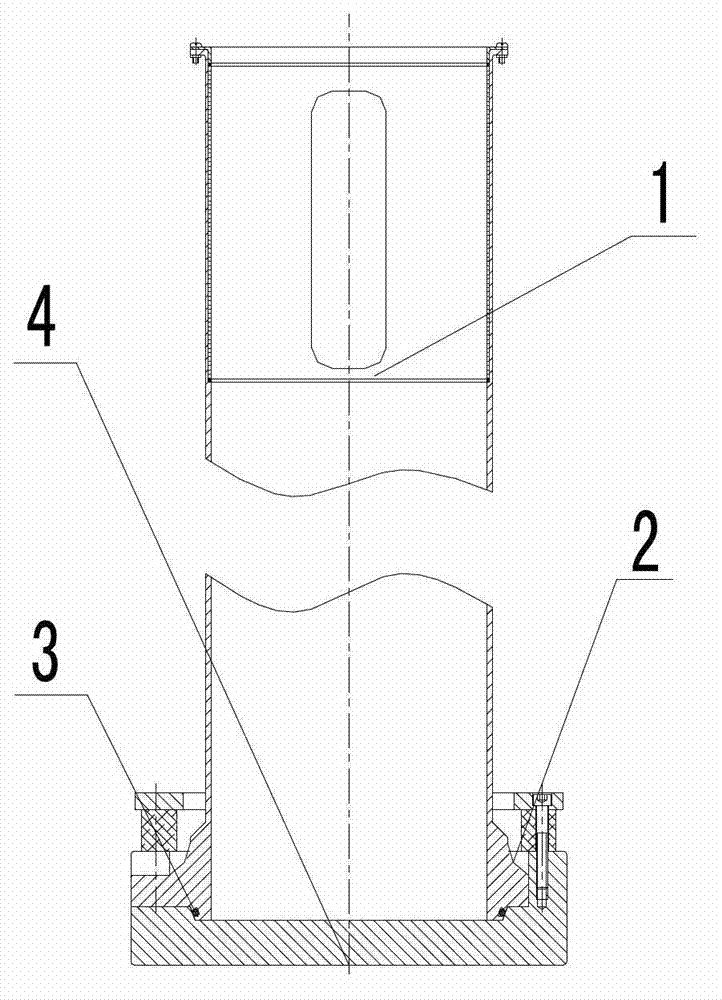

[0022] Such as figure 1 with figure 2 As shown: the present invention includes an upper cylinder body 1, a cylinder seat 4 and a limit ring. The upper edge of the cylinder seat 4 is evenly distributed with a plurality of cylinder seat protrusions 8 protruding upwards. Between adjacent cylinder seat protrusions 8 Grooves are formed, and the lower end edge of the upper cylinder 1 is evenly distributed with a plurality of upper cylinder bumps 7 protruding outward. In the groove, the thickness of the protrusion 7 of the upper cylinder is 8cm smaller than the height of the protrusion 8 of the cylinder seat. The limit ring includes the rubber ring 5 at the lower end and the limit steel ring 2 at the upper end. The limit ring is set on the upper cylinder 1 outside.

[0023] Such as figure 1 with figure 2 As shown: the limit ring is connected with the cylinder seat bump 8 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com