Composite material pipe applicable to spiral key connection and producing method for composite material pipe

A composite material tube and spiral key technology, applied in the direction of slender elements, building elements, etc., can solve the problem of low connection strength, achieve uniform force distribution, retain continuity, and avoid large connection spaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

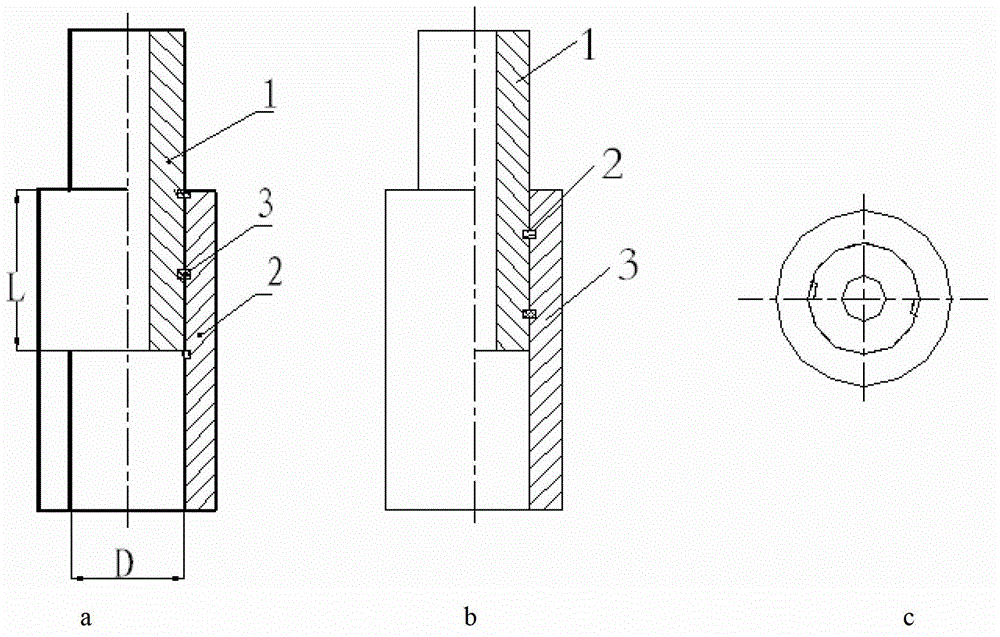

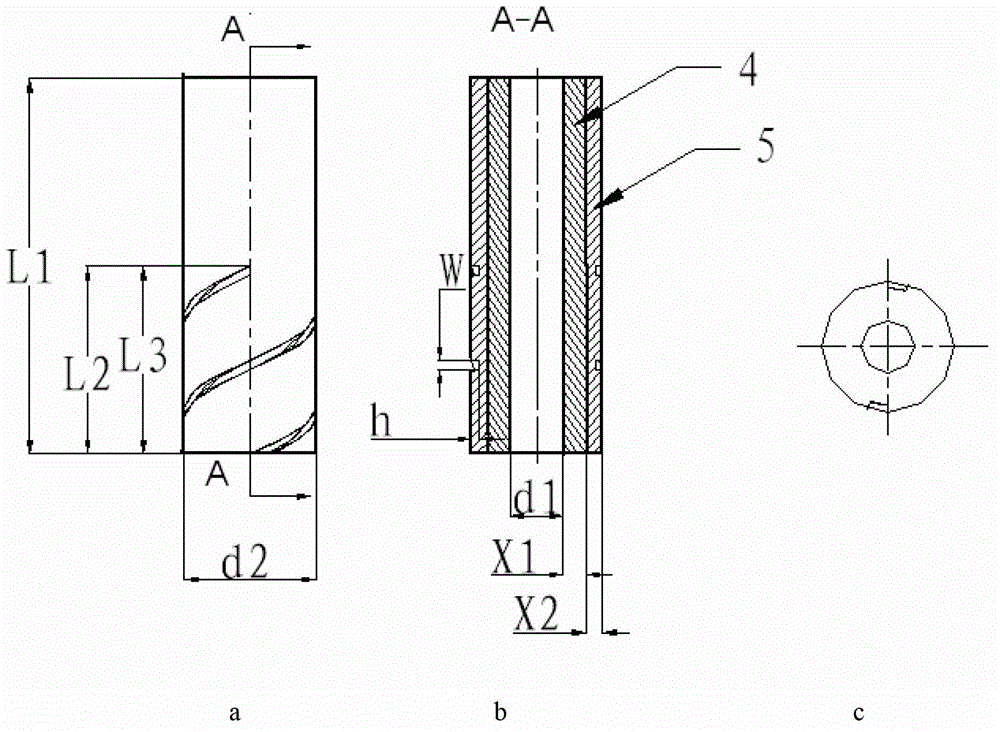

[0033] This embodiment is a kind of composite material tube suitable for spiral key connection. The composite material tube is to connect the inner tube 1 and the outer tube 3 through the screw key 3, the length L of the connection part is 100mm, and the diameter of the connection part is D is 70mm.

[0034] Both the inner tube 1 and the outer tube 2 are made of glass fiber prepreg and carbon fiber prepreg using the prior art. The tensile strength of the glass fiber prepreg is 300MPa, the resin content is 40%, and the thickness is 0.12mm; the tensile strength of the carbon fiber prepreg is 1000MPa, the resin content is 40%, and the thickness is 0.3mm. Both the inner tube 1 and the outer tube 2 are formed by a conventional winding process. The inner tube 1 has a wall thickness of 25 mm, and the outer tube 2 has a wall thickness of 20 mm.

[0035] There are two circumferentially uniform spiral grooves on the outer wall of the inner tube 1 and the inner wall of the outer tube 3...

Embodiment 2

[0045] This embodiment is a kind of composite material tube suitable for spiral key connection. The composite material tube is to connect the inner tube 1 and the outer tube 3 through the screw key 3. The length L of the connection part is 20mm, and the diameter of the connection part is D 10mm.

[0046] Both the inner tube 1 and the outer tube 2 are made of carbon fiber prepreg using the prior art. The tensile strength of the carbon fiber prepreg is 1000MPa, the resin content is 40%, and the thickness is 0.3mm. Both the inner tube 1 and the outer tube 2 are formed by a conventional winding process. The inner tube 1 has a wall thickness of 4mm, and the outer tube 2 has a wall thickness of 4mm.

[0047] There are two circumferentially uniform spiral grooves on the outer wall of the inner tube 1 and the inner wall of the outer tube 3 respectively. The inner diameter of the spiral key=the outer diameter of the inner tube-the cross-sectional height of the spiral key / 2; the oute...

Embodiment 3

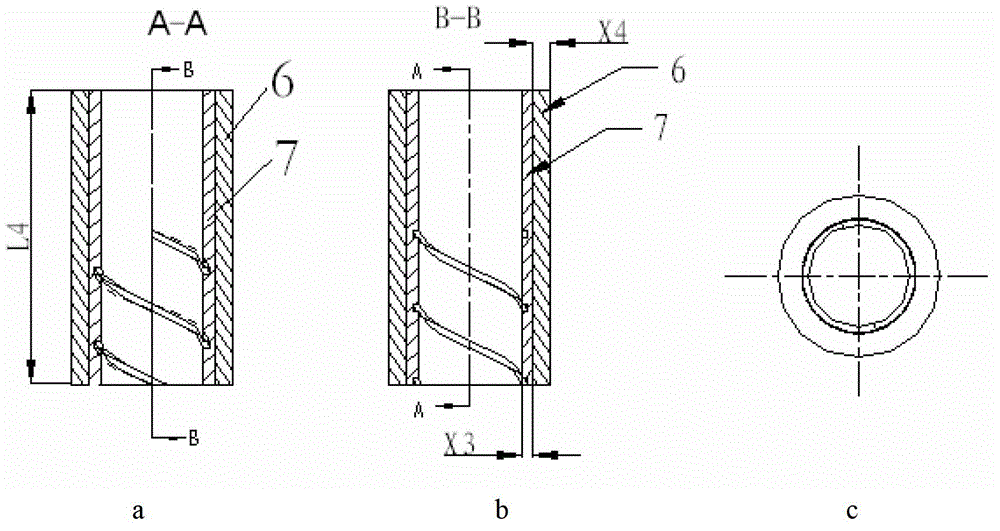

[0057] This embodiment is a composite material pipe suitable for spiral key connection. The connection composite material pipe is to connect the inner pipe 1 and the outer pipe 3 through the spiral key 3, the length L of the connection part is 400mm, and the diameter of the connection part is D is 220mm.

[0058] Both the inner tube 1 and the outer tube 2 are made of glass fiber prepreg using the prior art. The tensile strength of the glass fiber prepreg is 300MPa, the resin content is 40%, and the thickness is 0.12mm. Both the inner tube 1 and the outer tube 2 are formed by a conventional winding process. The inner tube 1 has a wall thickness of 60 mm, and the outer tube 2 has a wall thickness of 60 mm.

[0059] There are two circumferentially uniform spiral grooves on the outer wall of the inner tube 1 and the inner wall of the outer tube 3 respectively. The inner diameter of the spiral key=the outer diameter of the inner tube-the cross-sectional height of the spiral key / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com