Method for estimating the pinking intensity of an internal combustion engine by inverting a wave equation

一种内燃发动机、爆震强度的技术,应用在内燃活塞发动机、燃烧发动机、发动机的测试等方向,能够解决估计爆震强度、不允许等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

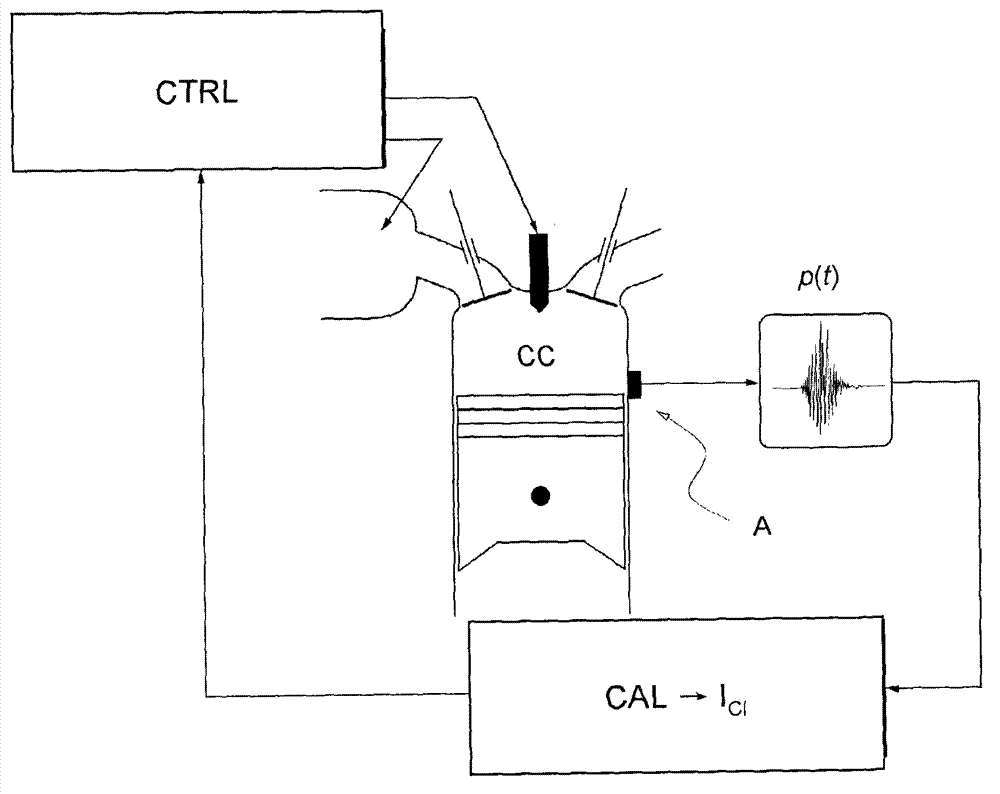

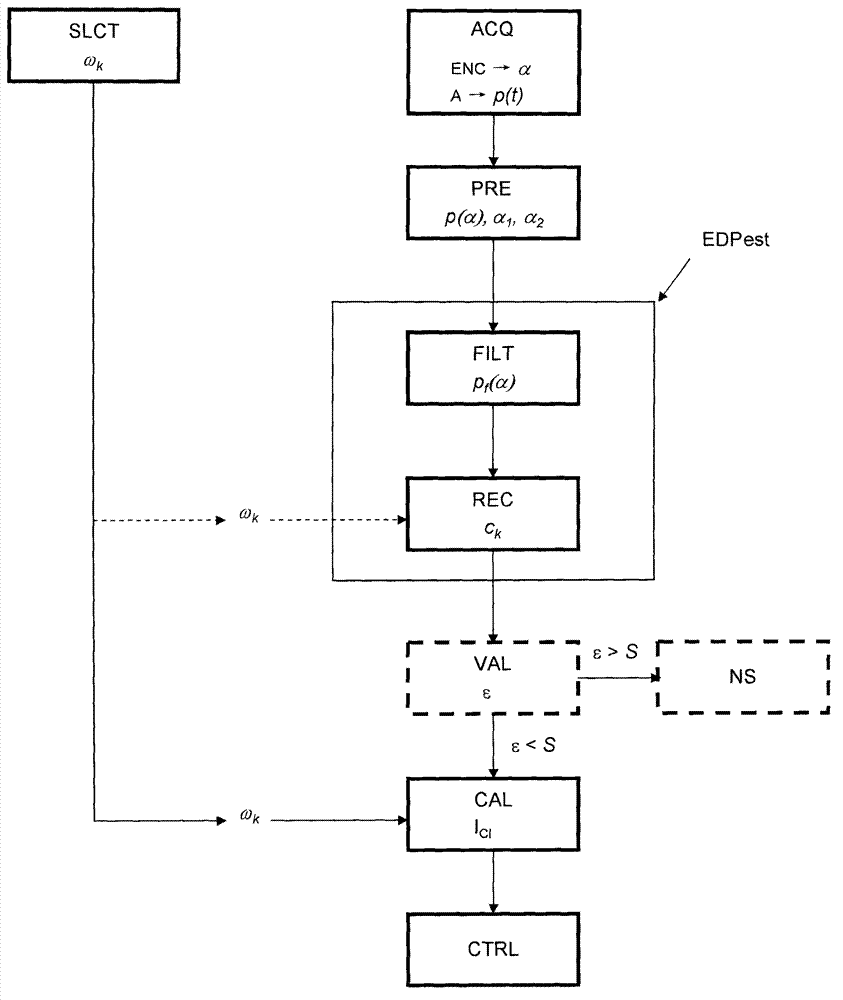

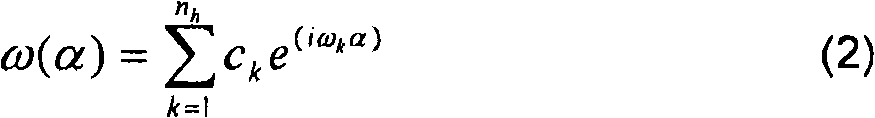

[0030] The method according to the invention relates to a method of combustion control of an internal combustion engine which takes into account the phenomenon of knocking. The method includes estimating the engine knock intensity by processing the signal sent by the sensor, and the signal has physical meaning for directly qualitative combustion and possible occurrence of knock. The method is independent of the nature of the combustion and the cylinder pressure sensor technology used.

[0031] The present invention is described in terms of a specific embodiment, where the method is described as applied to a single cylinder, and does not contain specificities associated with the combustion mode of the engine. According to this embodiment, a cylinder pressure sensor is used. The nature of the internal combustion engine and the cylinder pressure sensor technology used do not affect the principle of the method.

[0032] figure 1 The general principle of the control method accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com