Electron bombardment type evaporation source system

A technology of electron bombardment and evaporation source, applied in the field of electron bombardment evaporation source system, can solve problems such as affecting the quality of the film layer, and achieve the effects of high degree of automation, interference prevention and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

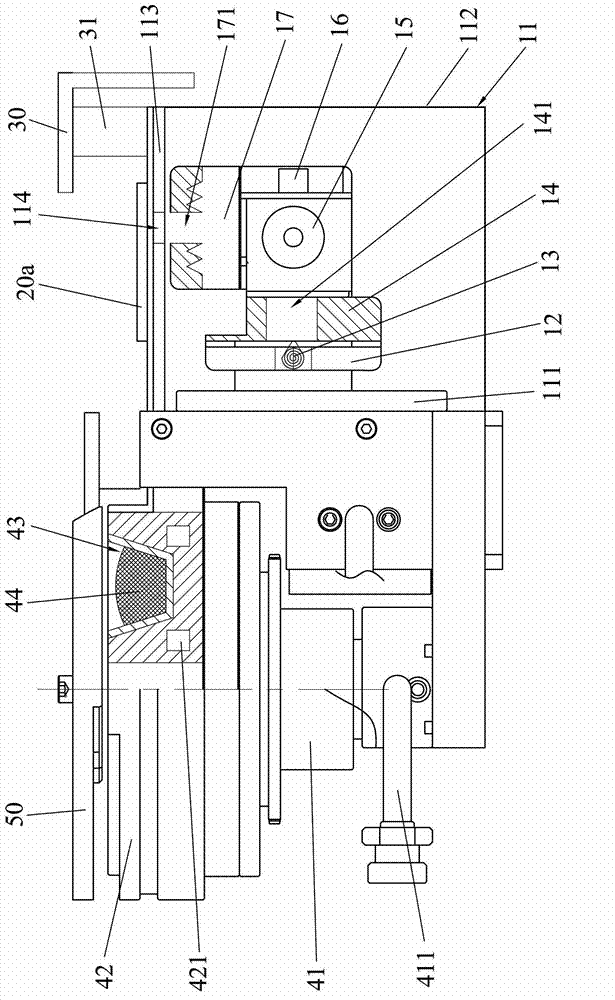

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

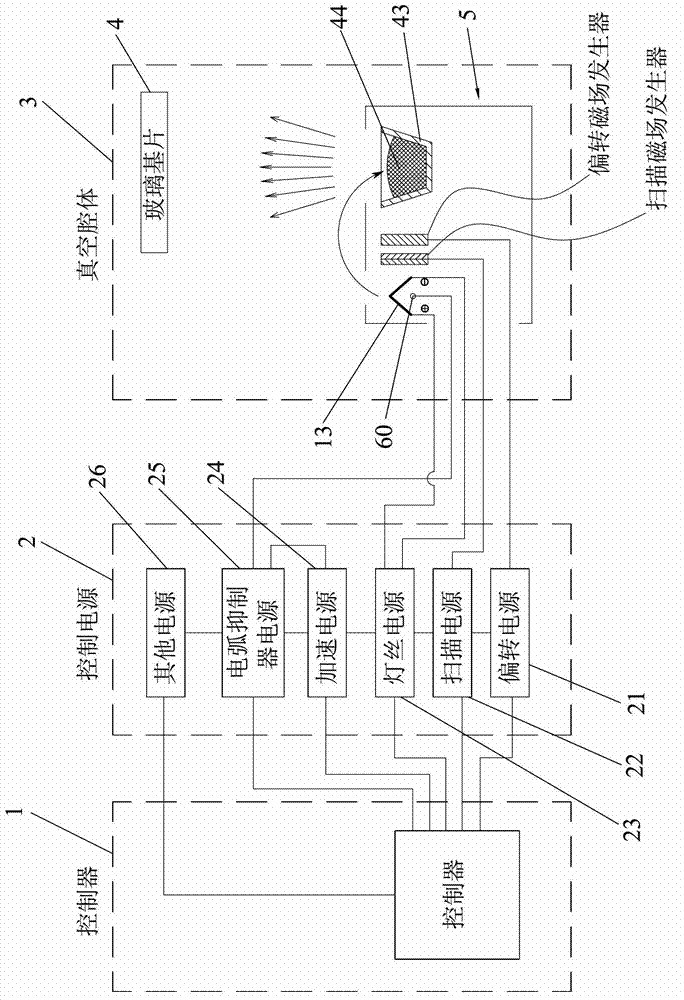

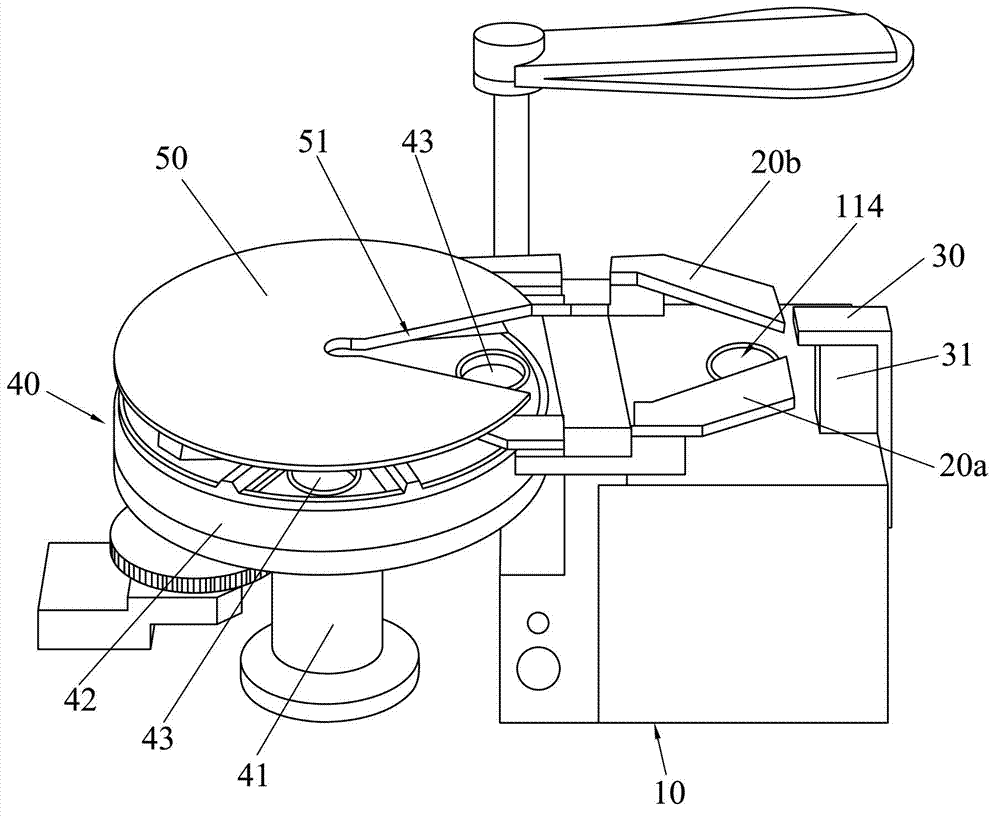

[0021] Such as figure 1 As shown, the electron bombardment evaporation source system provided by the present invention includes a controller 1 , a control power supply 2 and a vacuum chamber 3 . Wherein, the control power supply 2 includes a deflection power supply 21, a scanning power supply 22, a filament power supply 23, an acceleration power supply 24, an arc suppressor power supply 25 and other power supplies 26, and the above-mentioned power supplies are electrically connected to the controller 1 respectively; The coated glass substrate 4 is input and the glass substrate 4 is coated therein. An electron bombardment evaporation source 5 is arranged at a position below the glass substrate 4 in the vacuum chamber 3; Crucible 43, filament 13, arc suppressor 60, scanning magnetic field generator and deflection magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com