Process and equipment for producing laundry soap powder

A production process and production equipment technology, applied in the field of washing powder production, can solve the problems of increasing the difficulty of cleaning the dust removal system, reducing the active ingredients of soap powder products, and reducing the efficiency of the dust removal system, so as to increase the difficulty of cleaning, have good solubility, and avoid losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 (base powder production process and system, the following percentages are weight percentages)

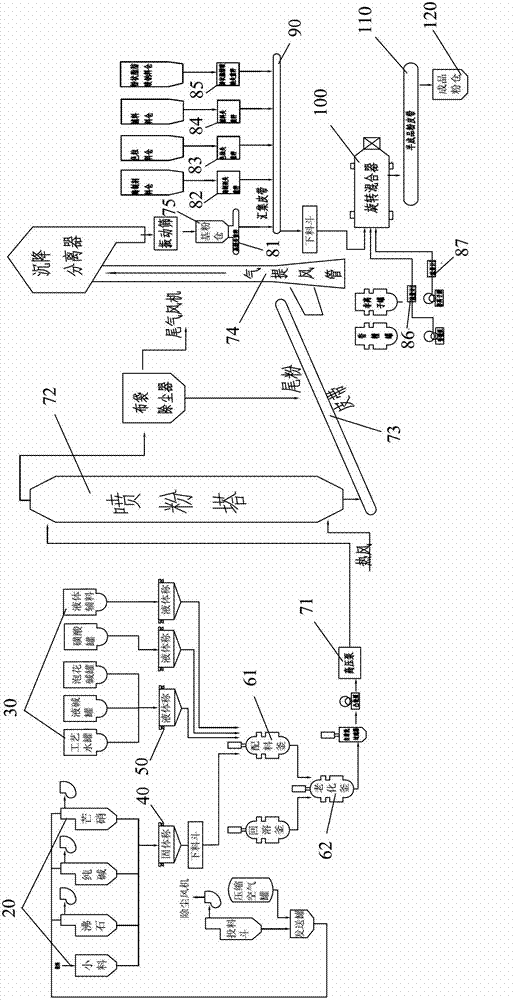

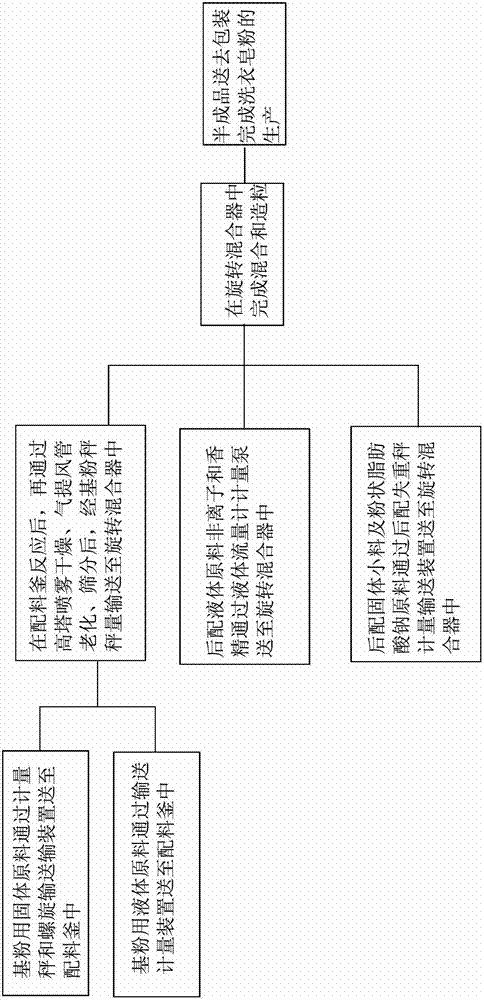

[0048] see figure 1 and 2 As shown, the solid raw materials Glauber's salt, soda ash, 4A zeolite, and small solid materials used in the base powder production system for producing base powder are sent to the solid raw material bin 20 through the solid raw material air conveying system. Liquid caustic soda, natron, sulfonic acid and process water are pumped into the liquid raw material header tank 30 respectively. After the liquid raw material is measured by the liquid raw material weighing scale 50, it is added into the batching pot 61, and the stirring device of the batching pot 61 is turned on. The solid raw material is added into the batching pot 61 after being measured by the solid material weighing scale 40 . The raw materials added in the batching pot 61 form slurry after being stirred, reacted and mixed. The slurry contains 18% soda ash, 20% 4A zeolite, 3...

Embodiment 2

[0051] (The after-mixing production process and system of washing powder base powder, powdery sodium fatty acid and other after-mixing raw materials, the following percentages are all weight percentages)

[0052] see figure 1 And and figure 2 As shown, the base powder from the powder spraying system is weighed 80% by the base powder loss-in-weight scale 81, and the discharge part of the soap powder loss-in-weight scale must be conveyed by a belt to prevent the material from being squeezed and agglomerated. Several solid raw materials from the rear batching bin are weighed 1% by enzyme preparation weight loss scale 82; Distribution of powdered raw materials. The powdery sodium fatty acid raw material is measured from a solid silo through a solid material loss-in-weight scale. The powdery sodium fatty acid weight loss scale 84 weighs 10%; the bottom of the feed bin of the rear batching bin should have a relatively large angle, so that under no external force, it is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com