Corn starch preparation method

A technology of corn starch and corn steep liquor, applied in the field of corn starch preparation, which can solve the problems of low concentration of concentrated corn steep liquor, excessive steam consumption, and affecting the drying capacity of the dryer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

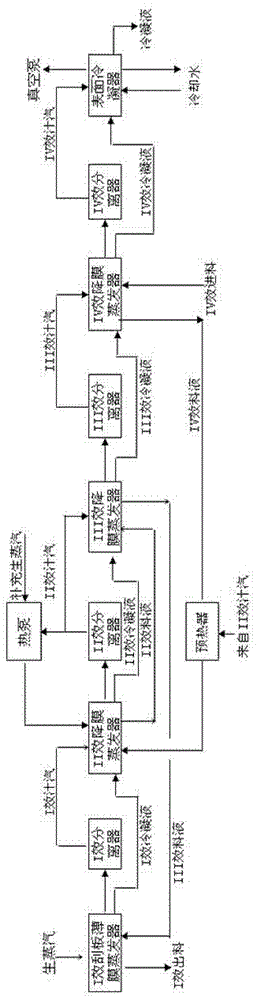

Image

Examples

preparation example Construction

[0012] The preparation method of corn starch provided by the invention comprises soaking corn kernels, concentrating the obtained corn soaking liquid, breaking the soaked corn kernels, separating the germ, and degerming the corn kernel tissue containing corn bran and endosperm Grinding, separating the fibers, separating the obtained coarse starch milk to obtain gluten water and starch milk, and washing the starch milk, wherein the method of concentrating the obtained corn steeping liquid includes evaporating the corn steeping liquid, and the evaporation The method comprises using a falling film evaporator to concentrate the corn steep liquor to 40-45% by weight, and using a scraped film evaporator to concentrate the resulting 40-45% by weight corn steep liquor to 48-52% by weight; preferably , using a falling film evaporator to concentrate the corn steep liquor to 40-42% by weight, and using a scraped film evaporator to concentrate the obtained 40-42% by weight corn steep liquo...

Embodiment 1

[0033] This embodiment is used to illustrate the preparation method of cornstarch provided by the present invention.

[0034] (1) Raw material pretreatment

[0035] Corn raw material (moisture content 14% by weight) is transported by the bucket elevator into the initial cleaning screen, iron remover, plane rotary cleaning screen for screening, stone removal, magnetic separation and other purification processes;

[0036] (2) Soak

[0037] After the purified corn is metered, it is hydraulically transported to the soaking tank, and is countercurrent soaked with a sulfurous acid aqueous solution with a concentration of 0.25% by weight. There are 10 soaking tanks, and the capacity of each tank is 50 tons of the above-mentioned purified corn raw materials. Part of the soaking liquid in the soaking tank circulates itself through the pump, and a part flows in the opposite direction to the added corn, that is, the newly added corn is soaked with old acid. Long-term corn is soaked wit...

Embodiment 2

[0051] This embodiment is used to illustrate the preparation method of cornstarch provided by the present invention.

[0052] Cornstarch is prepared according to the method of Example 1, the difference is: in the evaporation process of step (3), the 50 ° C corn soaking liquid extracted from the soaking tank (about 25m3 per tank) 3 , dry matter content is 8% by weight) pumped in the fourth effect falling film evaporator in the multi-effect evaporation system (controlling the flow of corn soaking liquid is 6.2m 3 / h), at a heating temperature of 70°C and a vacuum of 0.068MPa, the corn soaking liquid is cyclically heated and evaporated to obtain a four-effect corn slurry liquid with a concentration of 10% by weight and a four-effect juice vapor at 52°C , the four-effect juice vapor is connected to the vacuum pump through the tube condenser, and the four-effect corn slurry liquid is extracted (the flow rate of the control feed liquid is 5-6m 3 / h) and preheated to 88°C and then pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com