Repairing method for connecting rod for reeling machine jaw

A repair method and connecting rod technology, applied in the direction of adopting mechanical devices, mechanical measuring devices, mechanical gap measurement, etc., can solve problems such as increased gap between jaws, deformation of fan-shaped plates, long cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

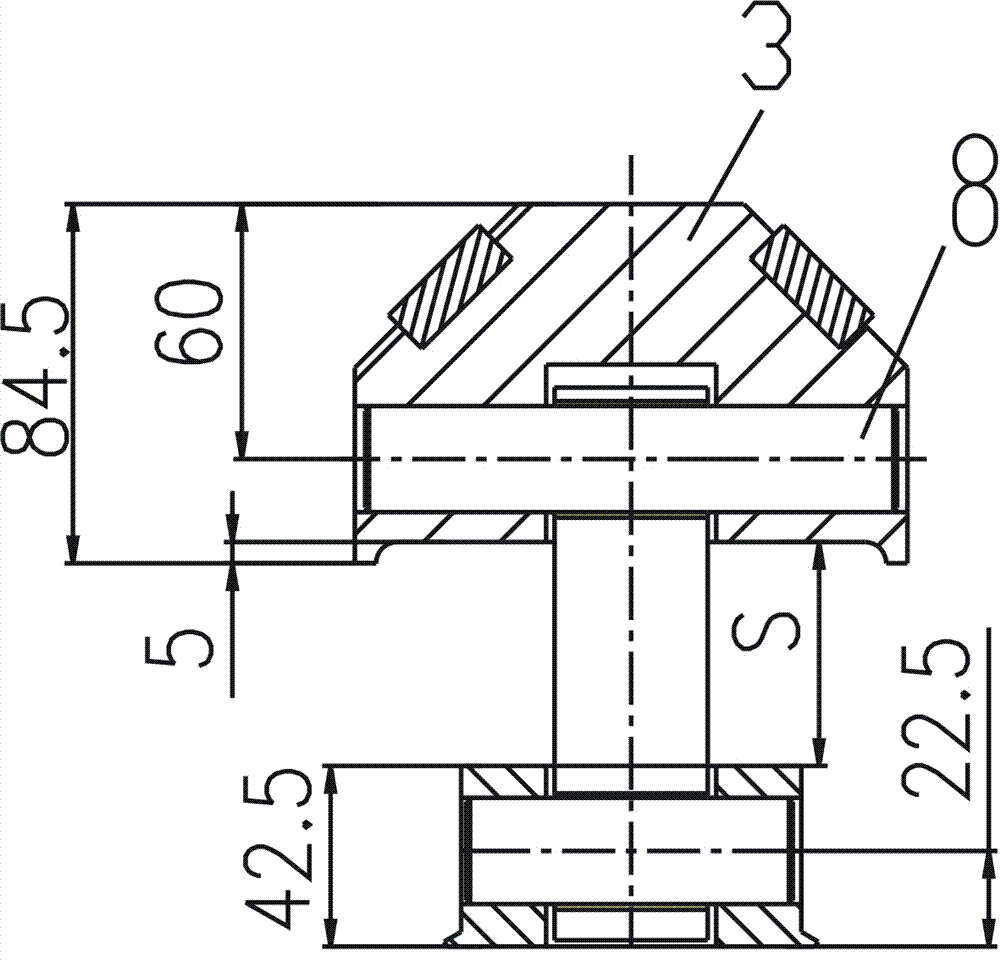

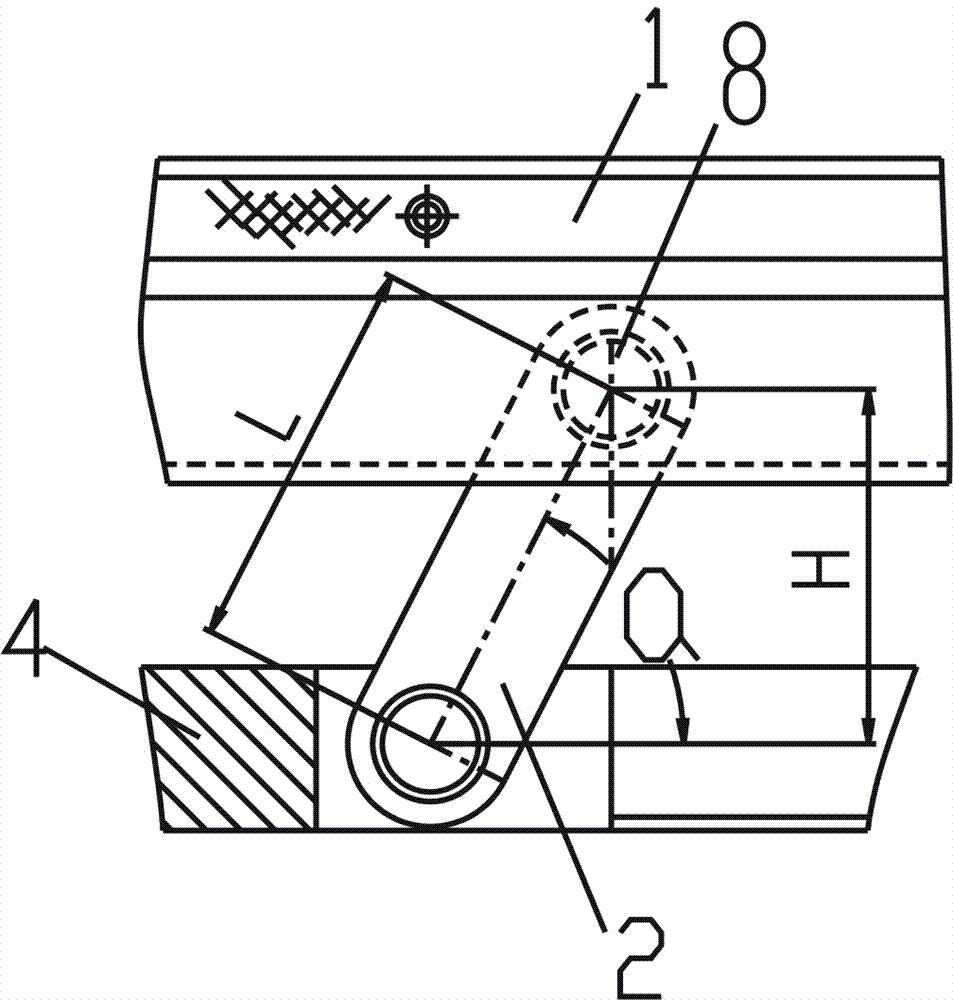

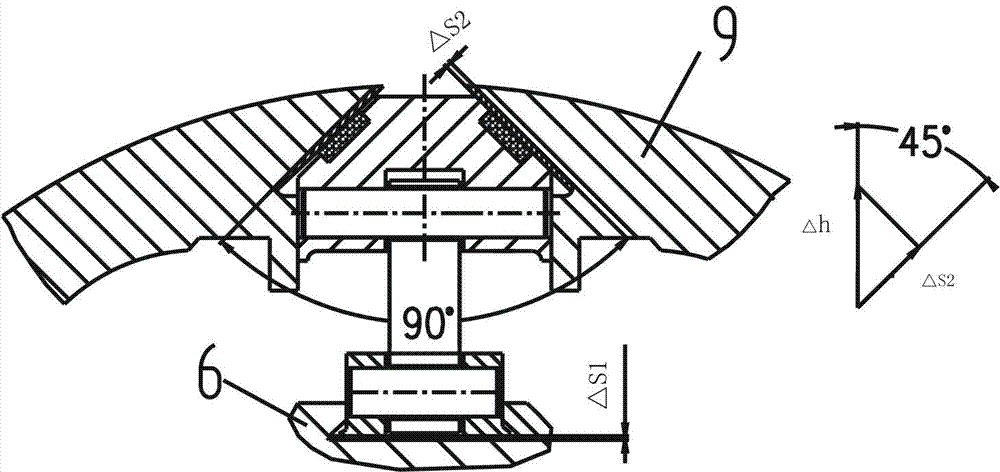

[0023] as attached figure 1 As shown, it is a schematic diagram of the assembly of the reel of the coiler, from the attached figure 1 It can be seen from the figure that the coiler reel includes a mandrel 7, on the outside of the mandrel 7 there are pyramidal shaft 6, fan-shaped plate 5 and jaw fan-shaped plate 9, above the mandrel is the jaw part of the coiler, the jaw The part is hinged in the form of a pin 8 by the connecting rod 2, the upper jaw brace 3 and the lower dovetail brace 4 on the inner side of the jaw iron 1, and the head of the steel plate is clamped and coiled under the compression of the spring force.

[0024] The key of the method of the present invention is the measurement of the connecting rod and the accurate conversion of the error. According to the difference in the wear and tear of the field use, the calculation formula increases and decreases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com