Hydrodynamic bearing intended to support a cylinder driven in rotation about its axis

A technology of fluid dynamic bearings and axis rotation, which is applied in the direction of rotating bearings, shafts and bearings, sliding contact bearings, etc. It can solve the problems of damaged bearing bushes and the reduction of liquid film thickness, etc., to reduce excessive pressure, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

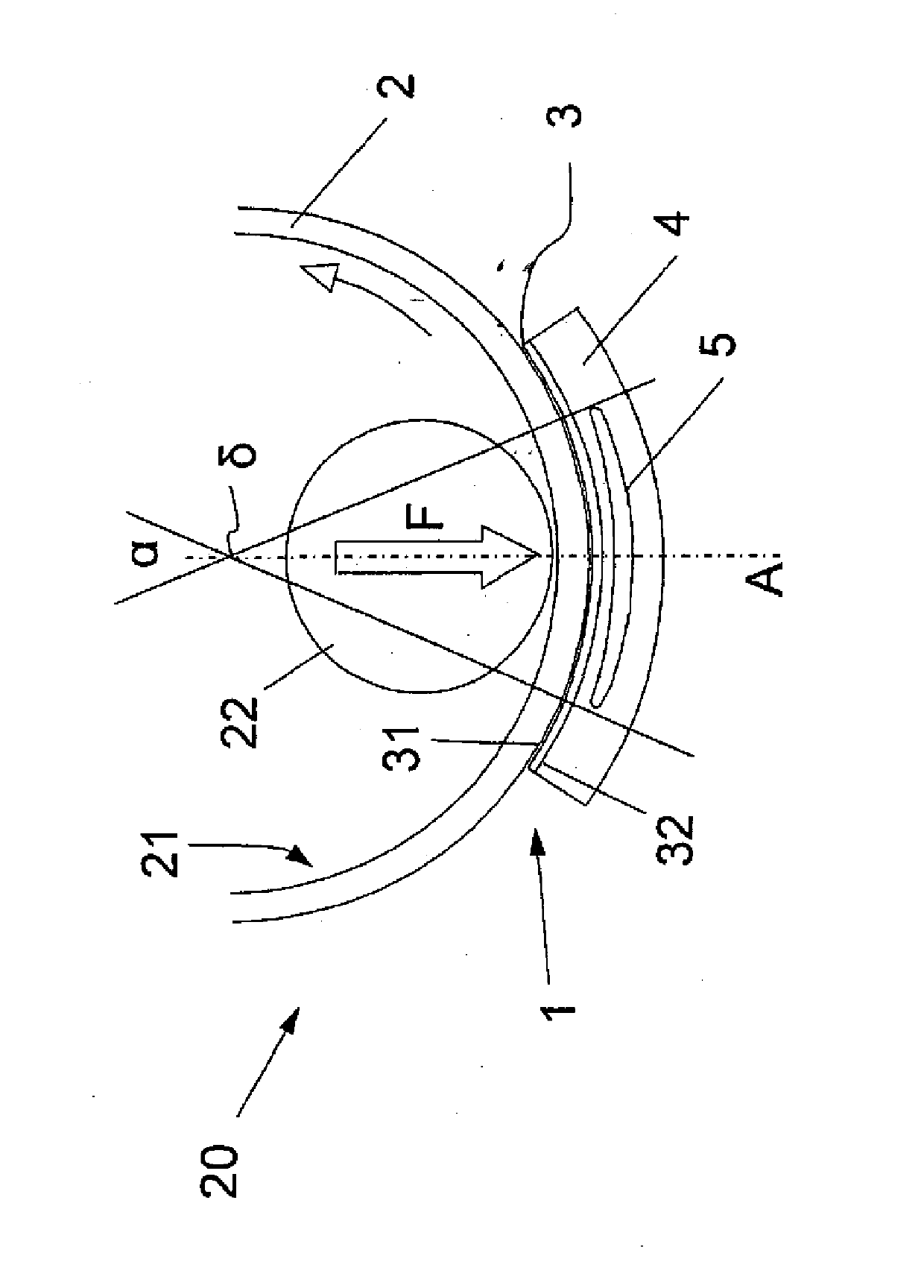

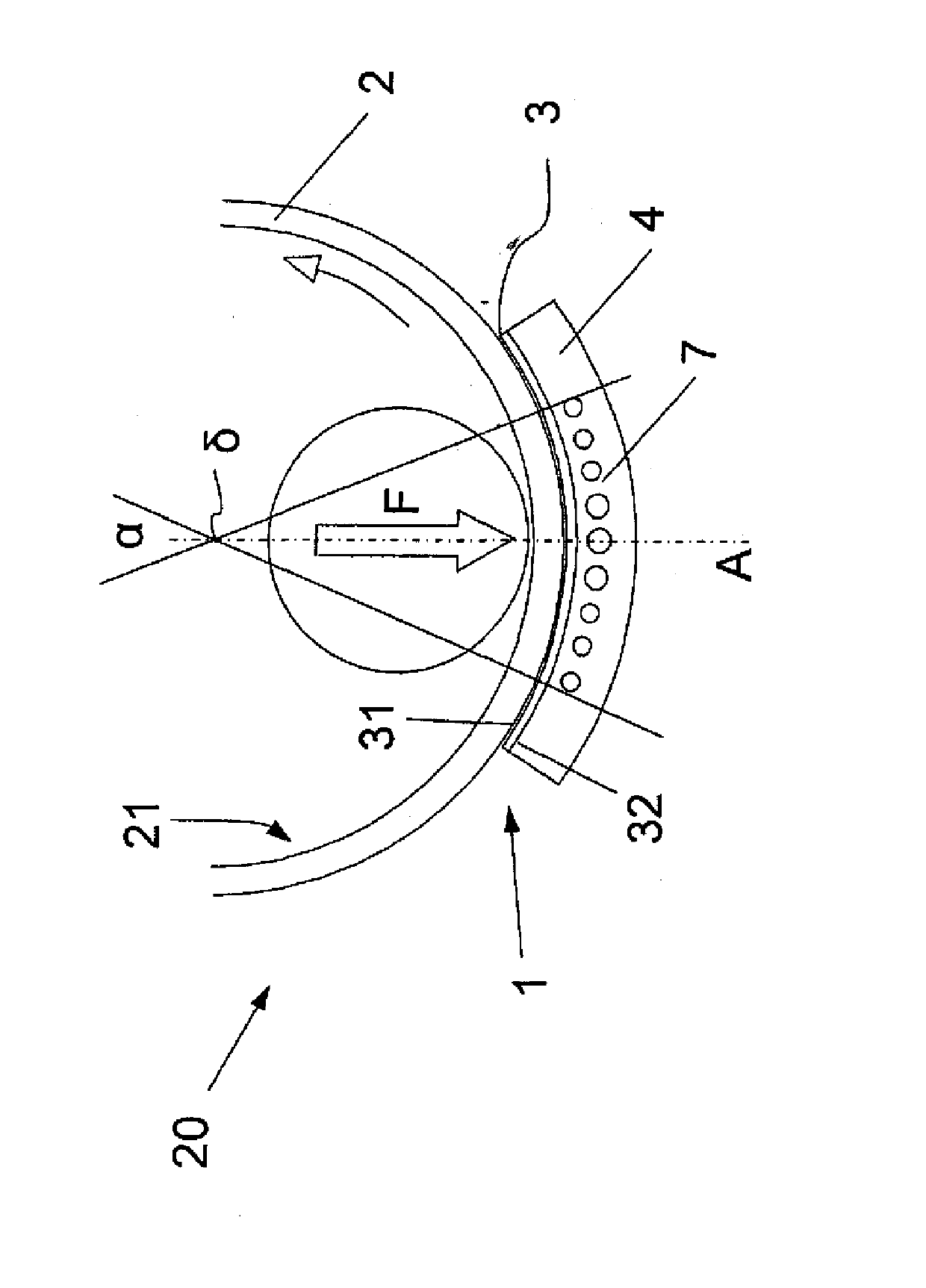

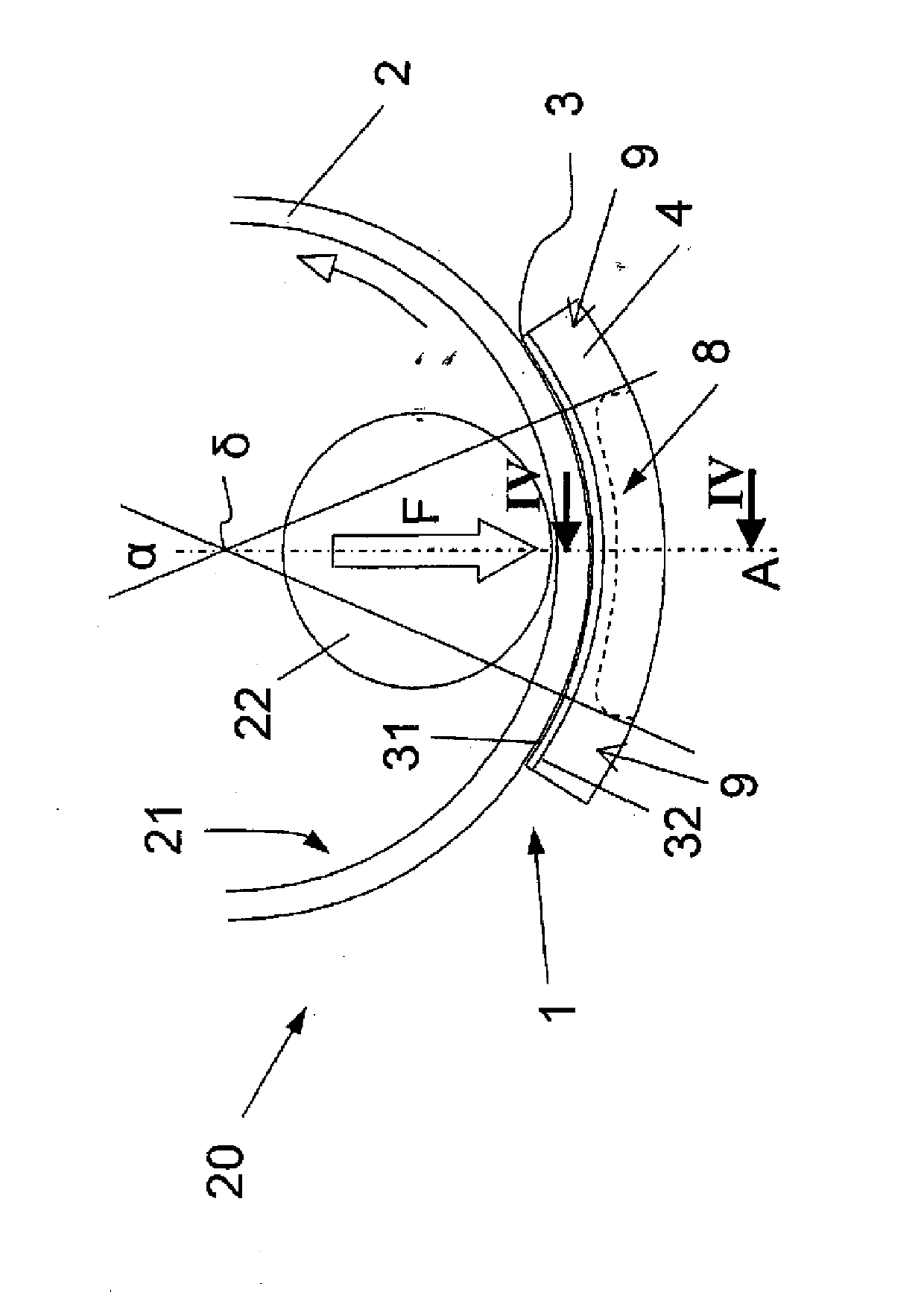

[0039] The invention relates firstly to a hydrodynamic bearing 1 for supporting a cylinder 2 driven in a rotational movement about its axis.

[0040] The diameter of the cylinder is greater than or equal to one meter. The cylinder is hollow and possibly radially deformable.

[0041] The bearing mainly consists of a bearing pad 3 and a bearing pad support member, wherein the bearing pad is especially made of a metal with low hardness (for example: bronze, babbitt alloy or other anti-friction metal), and the bearing pad support member is especially Made of a metal (eg steel) that is harder than the bearing pad.

[0042] The bearing pad 3 , in particular of constant thickness, extends along a part of the cylinder with axis δ and has a guide surface 31 intended to match the outer surface of the cylinder by means of a lubricating film.

[0043] This guide surface 31 has a radius of curvature corresponding to that of the cylinder 2 (greater than or equal to 0.5 m).

[0044] The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com