Intelligent substation inspection system

An intelligent inspection and substation technology, applied in information technology support systems, electrical components, circuit devices, etc., can solve the problems of reduced power supply reliability, excess maintenance, and no equipment maintenance, and achieve the effect of intelligent extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

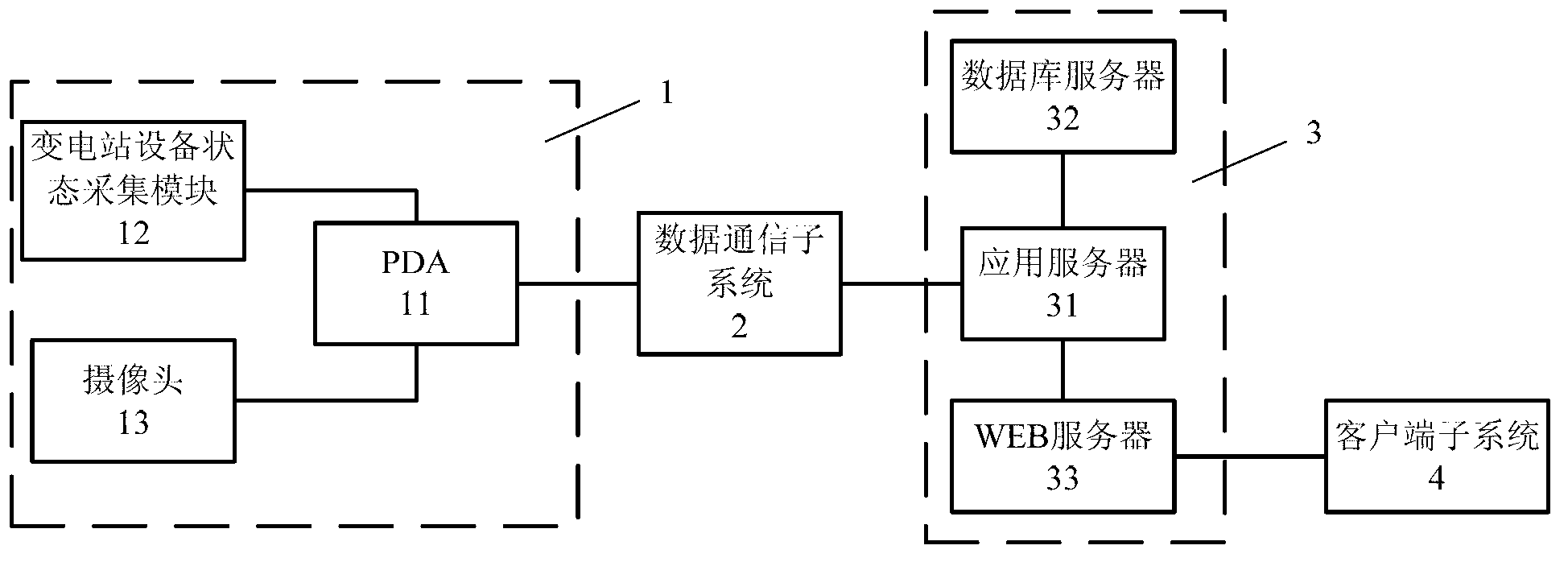

[0031] Such as figure 1 As shown, a substation intelligent inspection system includes a data acquisition subsystem 1, a data communication subsystem 2, a server subsystem 3 and a client subsystem 4, and the data acquisition subsystem 1 communicates with the server through the data communication subsystem 2 The subsystem 3 is connected, and the server subsystem 3 is connected to the client subsystem 4; the data acquisition subsystem 2 collects images and status information of substation equipment, and uploads them to the server subsystem 3 through the data communication subsystem 3, The server subsystem 3 stores and displays the received data, and remotely controls the data acquisition subsystem 1, and the client subsystem 4 acquires historical information of unattended substation equipment from the server subsystem 3 at any time , for remote intelligent inspection.

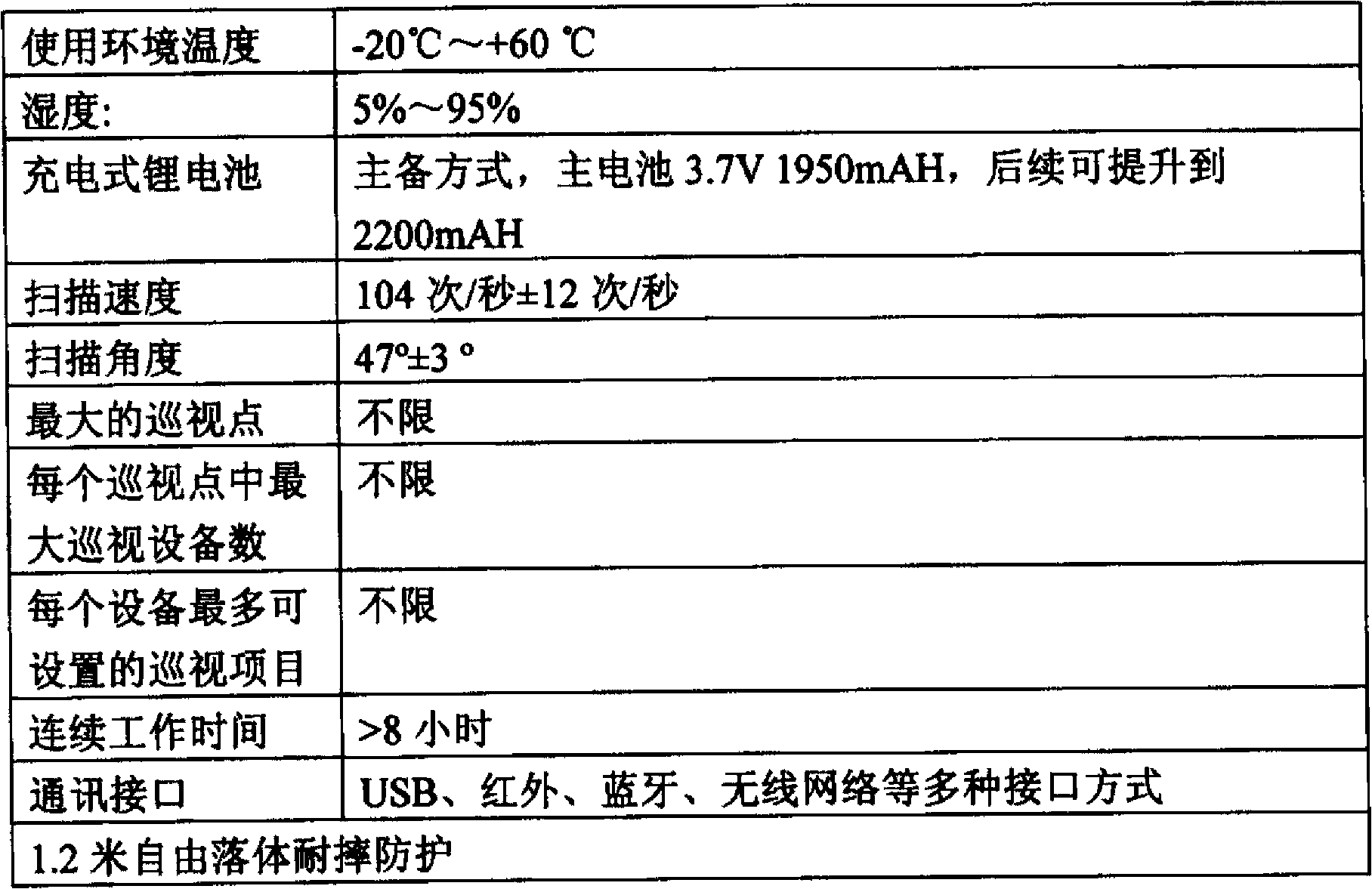

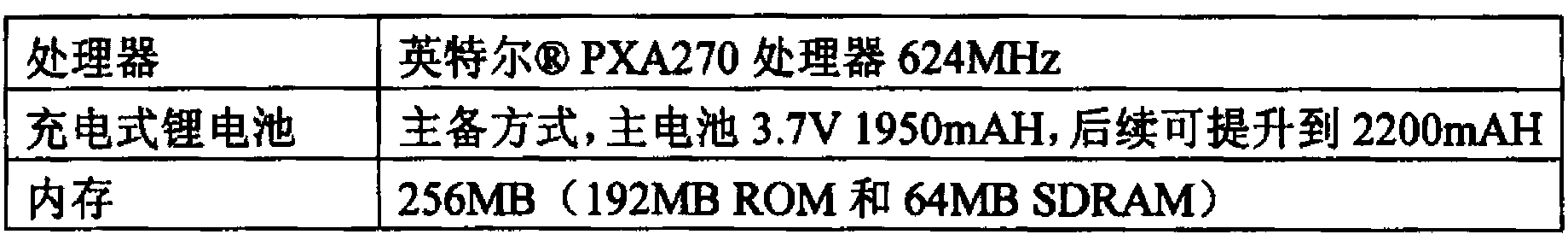

[0032] The data acquisition subsystem 1 includes a data collector, a substation equipment status acquisition m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com