Gas combustion method for primary reformer of methanol device and combustor for reformer

A methanol plant and gas combustion technology, applied in combustion methods, gas fuel burners, burners, etc., can solve problems such as increased investment and operating costs, flame fluttering, and inability to meet the heating temperature of reformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

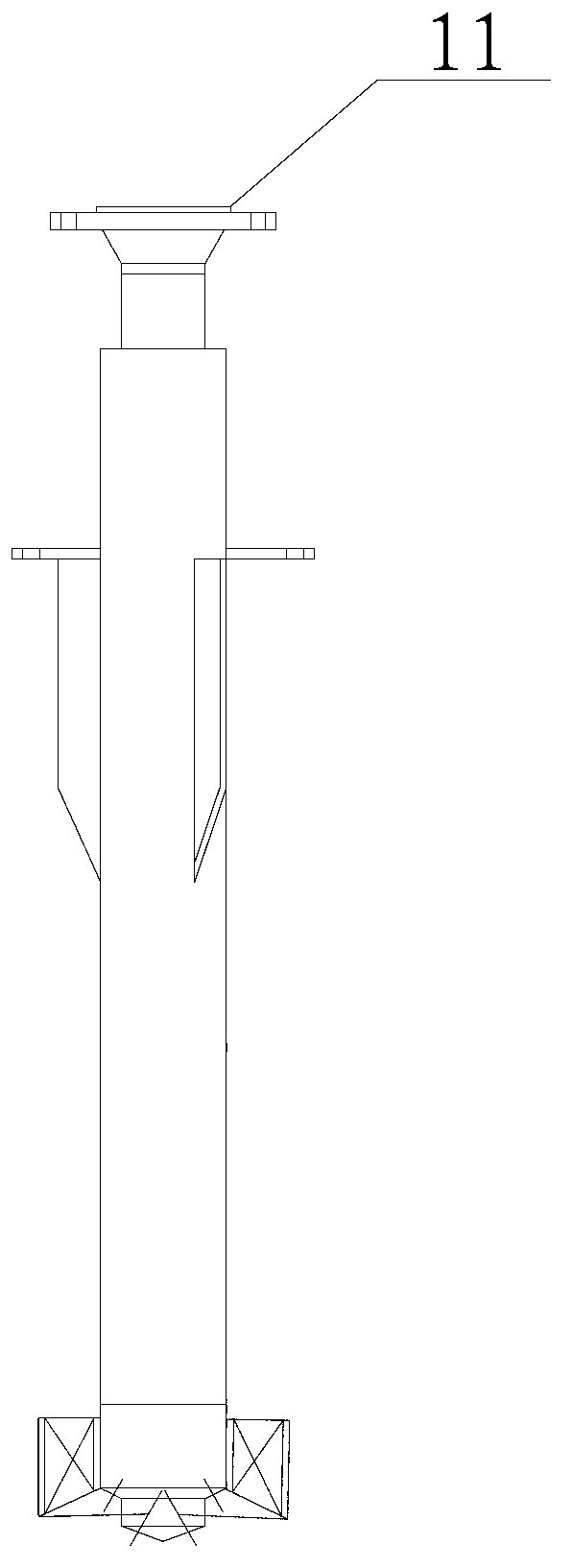

Image

Examples

Embodiment 1

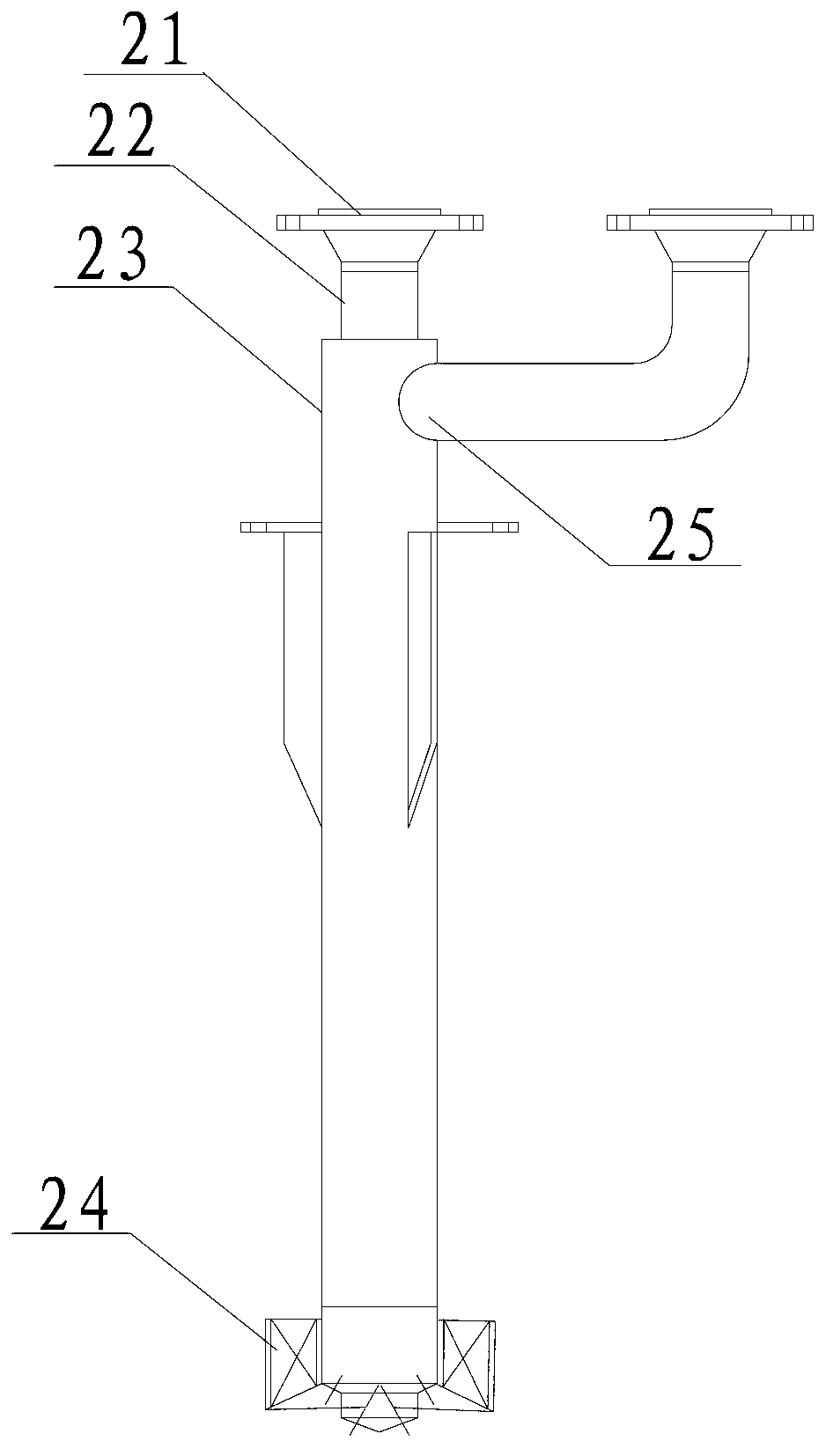

[0037] Pass the coke oven gas and high-pressure gas liquefied petroleum gas according to the ratio of 80%: 20% figure 2 Among them, the first embodiment of the present invention is used for combustion in the burner of the primary reformer of the methanol plant, and the jet momentum of the flame is measured to be 23015 (kgm / s) / MW.

Embodiment 2

[0039] Pass coke oven gas and high-pressure gas liquefied petroleum gas in a ratio of 70%: 30% figure 2 Among them, the first embodiment of the present invention is used for combustion in the burner of the primary reformer of the methanol plant, and the jet momentum of the flame is measured to be 25642 (kgm / s) / MW.

Embodiment 3

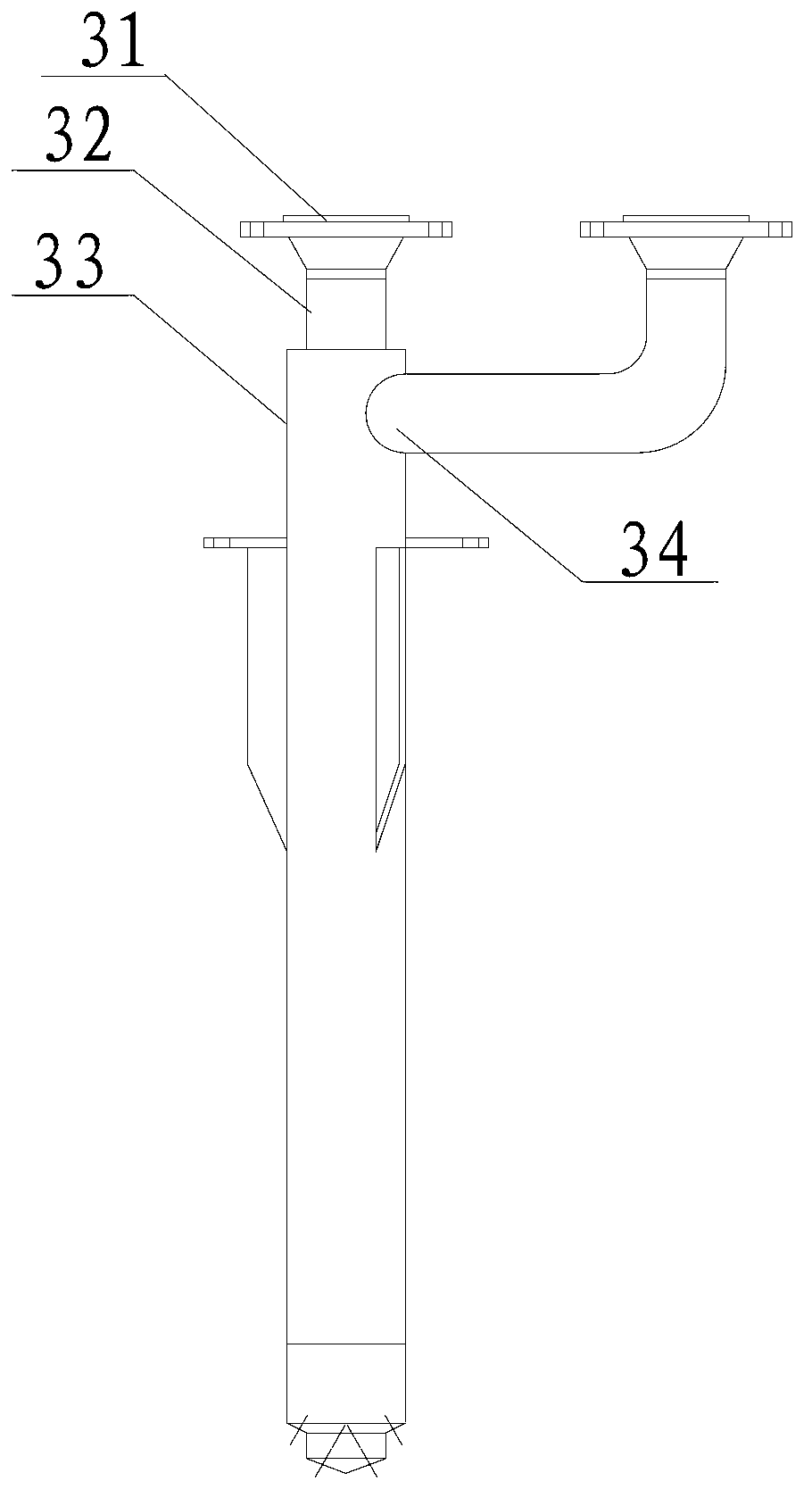

[0041] Pass coke oven gas and natural gas at a ratio of 50%:50% image 3 Among them, the second embodiment of the present invention is used for combustion in the burner of the primary reformer of the methanol plant, and the jet momentum of the flame is measured to be 31604 (kgm / s) / MW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com