A self-unloading one-way valve cylinder head valve plate assembly

A one-way valve and self-unloading technology, applied in the direction of variable capacity pump components, pump components, liquid variable capacity machinery, etc., can solve the problems of increased airflow resistance, increased motor power consumption, and failure to achieve sealing. Achieve the effects of reduced power consumption and cost, small deformation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

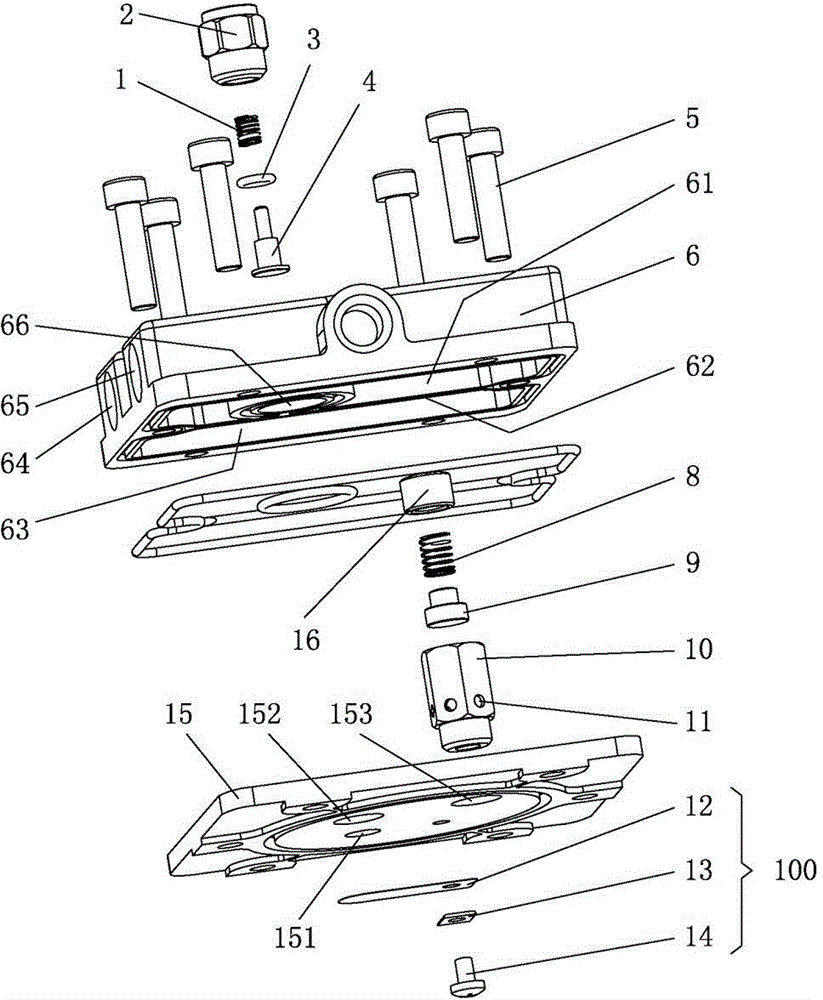

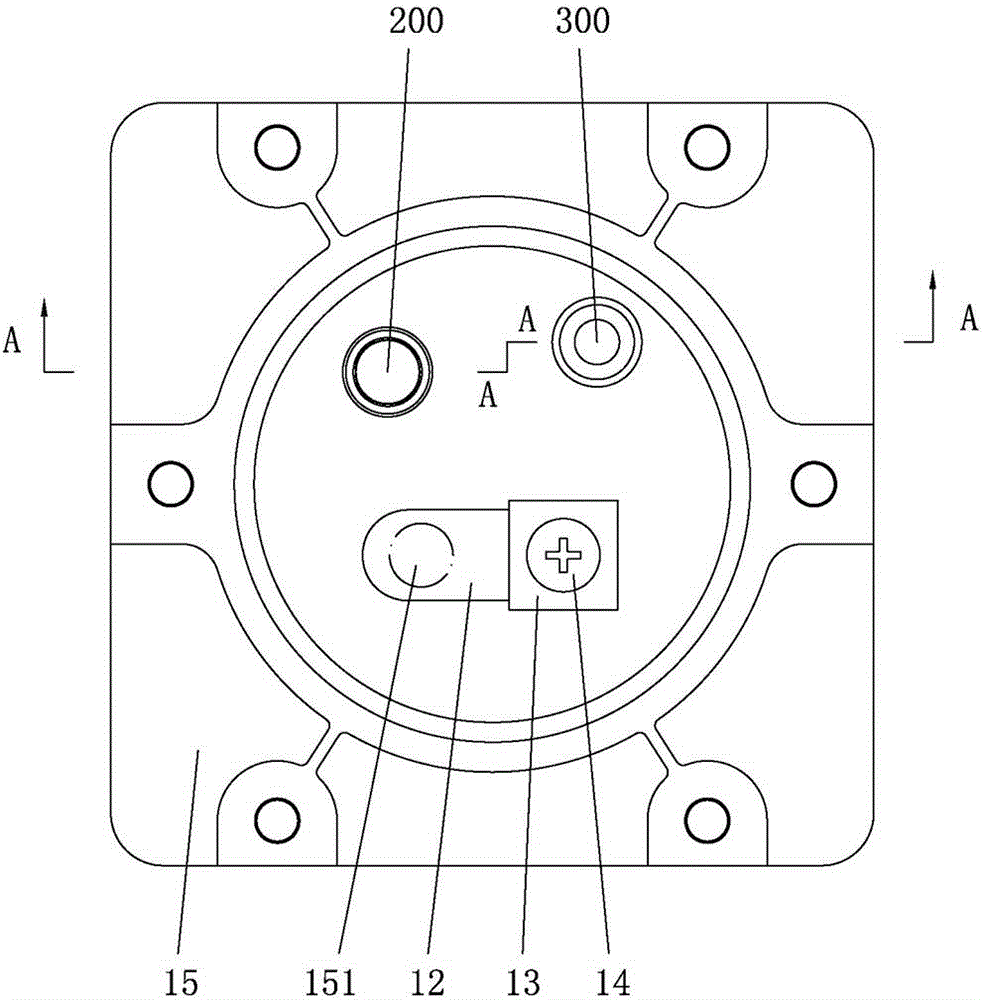

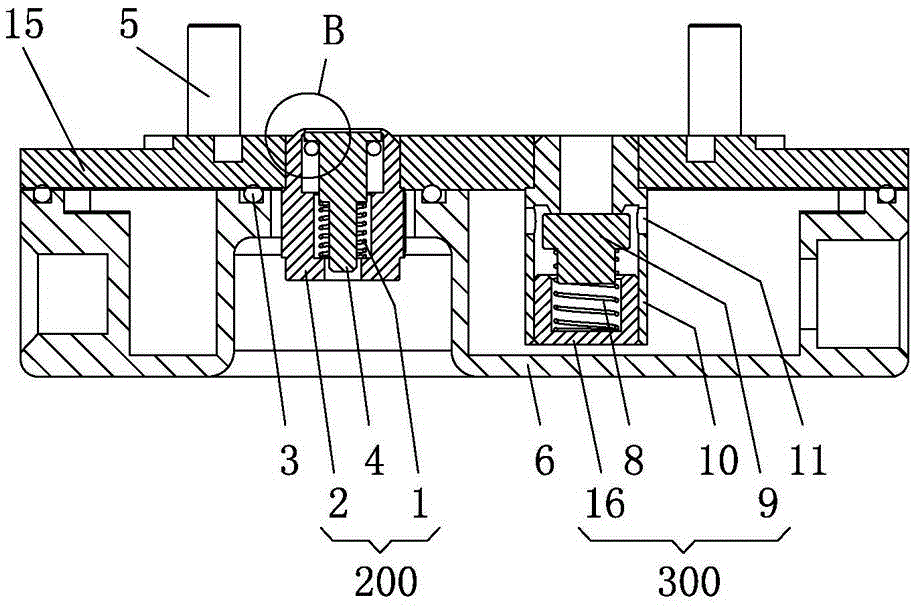

[0024] Such as figure 1 As shown in -4, a self-unloading check valve type cylinder head valve plate assembly includes a valve plate 15, the middle part of the valve plate 15 is formed with an air inlet 151 and an exhaust hole 153, and the lower side of the valve plate 15 is provided with a control inlet Air hole 151 unidirectionally conducts the intake valve plate assembly 100, and a check valve 300 is installed on the exhaust hole 153. The check valve 300 includes a valve body 10, and a valve cover 16 is installed on the upper end of the valve body 10. 10 is provided with a spool 9 and a spring 8, one end of the spring 8 is against the bonnet 16, and the other end presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com