Connecting method of rubber water stopping band and copper water stopping sheet

A technology of rubber waterstop and connection method, applied in water conservancy projects, marine engineering, construction and other directions, to achieve the effects of reliable connection, simple operation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

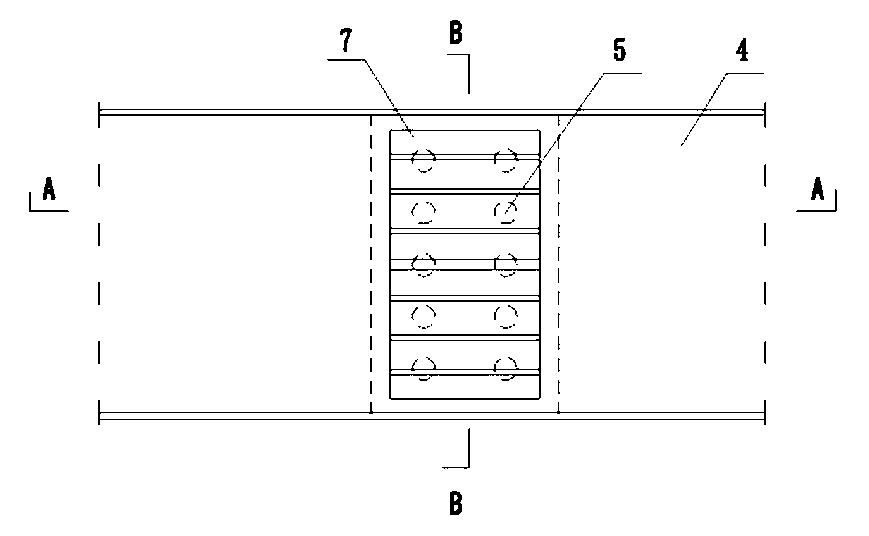

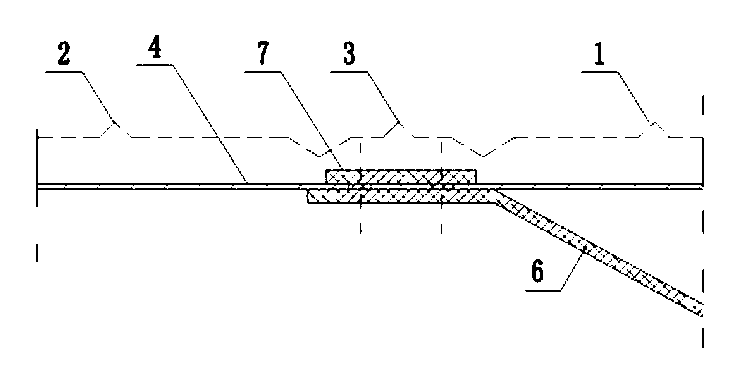

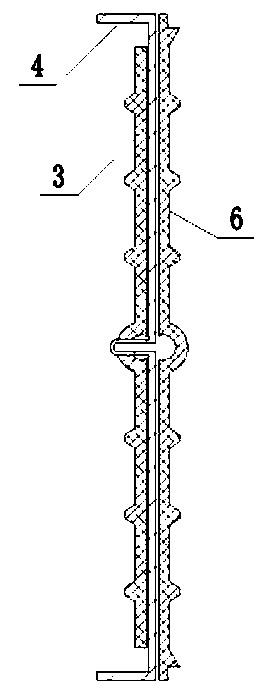

[0014] Such as Figure 1-3 As shown, the connection method of the rubber waterstop of the present invention and the copper waterstop is carried out according to the following steps:

[0015] The first step, on the copper water-stop sheet 4 at the position of the transition section 3 between the two water-stop sections 1 and one water-stop section 2 at the joint of the pond plate, space apart along the width direction of the copper water-stop section 4 Two rows of through holes 5 are arranged in a row, the diameter of which is 30 millimeters, and its quantity is subject to not affecting its strength;

[0016] The second step is to attach the ends of the rubber waterstops 6 of the two waterstops 1 to the surface of one side of the copper waterstop 4 at the position of the transition section 3, and place the other side corresponding to the copper waterstop 4 One side of the surface is covered with a rubber waterstop 7;

[0017] The third step is to connect the rubber waterstop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com