Sealant of supersonic-speed flame sprayed iron-based amorphous coating and application of sealant

A supersonic flame, iron-based amorphous technology, applied in coating, metal material coating process, fusion spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

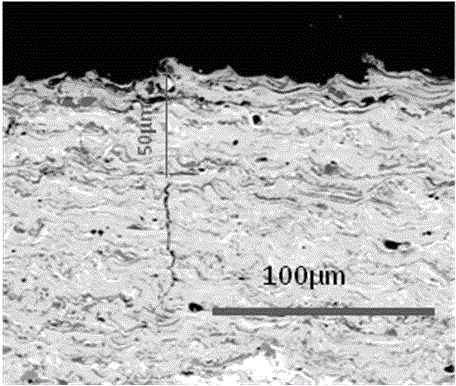

[0022] Sealing agent for amorphous coatings, the sealing agent is made of Al(OH) 3 and H 3 PO 4 composition, and the corresponding weight ratio is 1:3.5; wherein, the Al(OH) 3 It is an industrial grade white powder product, which contains Al 2 o 3 The mass fraction is 64.5%, and the powder mesh number is 1250 mesh; the H 3 PO 4 It is a viscous, non-volatile orthophosphate concentrated solution, with a mass fraction of phosphoric acid content of 85%. Heat the above sealing agent to 70°C, wait until it reacts into a clear solution, and apply the sealing agent evenly by brushing. Coated on the surface of the coating, the base is 304 stainless steel base, let it stand at room temperature for 12 hours, so that it can fully penetrate into the pores of the coating, and then put the sealed spray coating into a drying oven to heat, and then heat it at 100 ° C, 200 °C and 250 °C respectively for 2 hours to obtain a thermal spray coating.

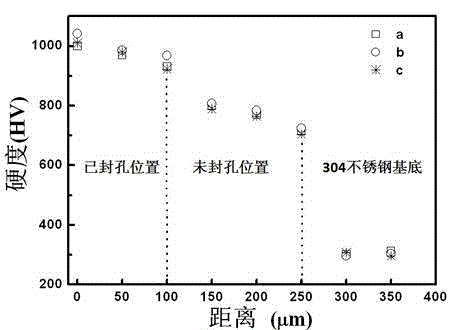

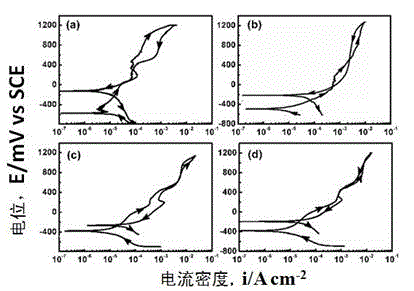

[0023] Performance Testing:

[0024...

Embodiment 2

[0026] Sealing agent for amorphous coatings, the sealing agent is made of Al(OH) 3 and H 3 PO 4 composition, and the corresponding weight ratio is 1:4.2; wherein, the Al(OH) 3 It is an industrial grade white powder product, which contains Al 2 o 3 The mass fraction is 64.5%, and the powder mesh number is 1250 mesh; the H 3 PO 4 It is a viscous, non-volatile orthophosphate concentrated solution, with a mass fraction of phosphoric acid content of 85%. Heat the above sealing agent to 70°C, wait until it reacts into a clear solution, and apply the sealing agent evenly by brushing. Coated on the surface of the coating, the base is 304 stainless steel base, let it stand at room temperature for 12 hours, so that it can fully penetrate into the pores of the coating, and then put the sealed spray coating into a drying oven to heat, and then heat it at 100 ° C, 200 ℃ and 250 ℃ respectively for 2 hours.

[0027] Performance Testing:

[0028] The test results show that the coa...

Embodiment 3

[0030] Sealing agent for amorphous coatings, the sealing agent is made of Al(OH) 3 and H 3 PO 4 Composition, and the corresponding weight ratio is 1:5; wherein, the Al(OH) 3 It is an industrial grade white powder product, which contains Al 2 o 3 The mass fraction is 67%, and the powder mesh number is 1250 mesh; the H 3 PO 4It is a viscous, non-volatile orthophosphate concentrated solution, the mass fraction of phosphoric acid content is 90%, the above sealing agent is heated to 70°C, and after it reacts into a clear solution, the sealing agent is evenly applied by brushing. Coated on the surface of the coating, the base is 304 stainless steel base, let it stand at room temperature for 12 hours, so that it can fully penetrate into the pores of the coating, and then put the sealed spray coating into a drying oven to heat, and then heat it at 100 ° C, 200 ℃ and 250 ℃ respectively for 2 hours.

[0031] Performance Testing:

[0032] The test results show that the coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com