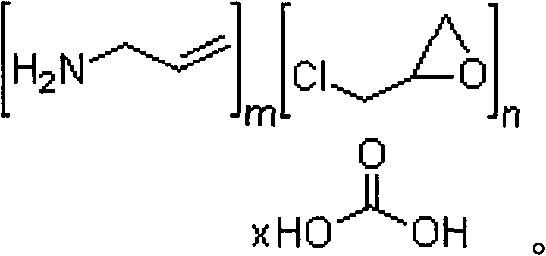

Method for preparing sevelamer carbonate

The technology of sevelamer carbonate and sevelamer hydrochloride is applied in the field of biomedicine, and can solve the problems of high impurity content of sevelamer carbonate, affecting the quality of sevelamer carbonate, affecting the quality of final products, etc. Reaction time and solvent, strong anti-pollution ability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0058] Preparation of polyallylamine hydrochloride

[0059] Add 800g of water, 500g of allylamine hydrochloride monomer, and 4.26g of benzoyl peroxide initiator in a 3000 ml four-neck flask equipped with a stirrer, a thermometer, and a reflux condenser. Adjust the rotation speed under stirring, then raise the temperature to 45°C, keep it warm for 10 hours, then raise the temperature to 85°C and keep it warm for 8 hours, cool down and discharge, wash with water, wash with methanol Soxhlet extraction, and dry to obtain 500g of white granules as the target product.

preparation example 2

[0061] 1,3-dichloroglycerin preparation method (1)

[0062] Add 2 kg of epichlorohydrin into the reaction kettle, lower the temperature to -10°C, add hydrochloric acid dropwise under stirring, react at the same temperature for 10 hours after adding, and let stand overnight. The next day, add sodium carbonate to neutralize to neutral, let stand and separate layers, separate 1,3-dichloroglycerin, extract the water layer with dichloromethane for three times, combine the extracts, recover dichloromethane under normal pressure, and the raffinate The 96-100°C / 50mmHg fraction was collected by fractional distillation to obtain 2.4 kg of the target product with a content of 99.5% and a yield of 86%.

preparation example 3

[0064] 1,3-dichloroglycerin preparation method (2)

[0065] Mix 8kg of glycerin and 670g of glacial acetic acid and heat to 100°C, pass through 7.8kg of dry hydrogen chloride gas, cool down after passing through enough, neutralize with solid sodium carbonate to pH 7.5, cool and filter sodium chloride, distill the filtrate under reduced pressure, and collect 96 -100°C / 50mmHg fraction, 7.5kg, yield 90%, purity 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com