Glue pot of glue spraying type thread-free glue binding machine

A wireless glue binding machine and glue-spraying technology, which is applied in binding adhesives, book binding, printing, etc., can solve the problems of hot-melt adhesive bonding performance degradation, difficult control of glue temperature, and pollution of the working environment. Easy to achieve glue temperature, short melting time and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

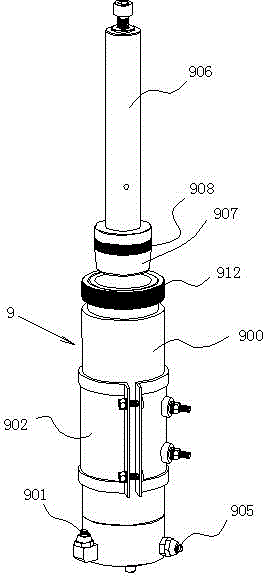

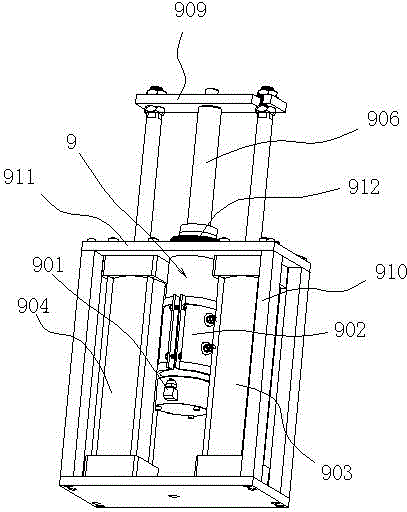

[0031] Such as Figures 1 to 9As shown, a glue tank of a glue-spraying wireless glue filling machine, the glue tank 9 includes a vertically arranged cylindrical glue chamber 900, the bottom of the glue chamber 900 is sealed, and the inside of the glue chamber 900 is sealed. A pressure piston 906 that can slide up and down is provided. The pressure piston 906 includes a piston head 907 located at the end of the pressure rod 906. The middle part of the piston head 907 is provided with an annular piston push piece 908. The ring piston push piece 908 The material is tetrafluoroethylene, the other end of the pressure rod 906 is connected with the piston rods of the left and right cylinders 904, 903 arranged on both sides of the glue tank 9 through a cross brace 909, and the tops of the left and right cylinders 904, 903 It is fixed on the inside of the top plate 911 of the frame 910 by bolts, and the glue tank 9 is fixed on the inside of the top plate 911 by the glue tank locking ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com